As technology advances, blister packing machines continue to evolve with features such as intelligent control systems, remote monitoring capabilities, and data analytics for performance optimization. These advancements aim to improve efficiency, reliability, and product safety in blister packaging operations. The machine not only protects products from external factors, but also improves productivity, saves labor costs, and ensures consistent quality during the packaging process. It forms the bottom by injecting mold and a bubble cover to protect products from out factors in manufacturing, transportation, storage, etc., and can better meet the needs of end users. More, the machine can also improve the efficiency of the production line through automatic error scheduling, transfer and sorting of different products, and is able to realize a high-speed production line.

1. Process

Parameter setting → blister formation (including PVC heating, PVC blister blow molding) → product loading → blister heat sealing →creasing → mechanical traction → finished product cutting discharge

2. Working Principle

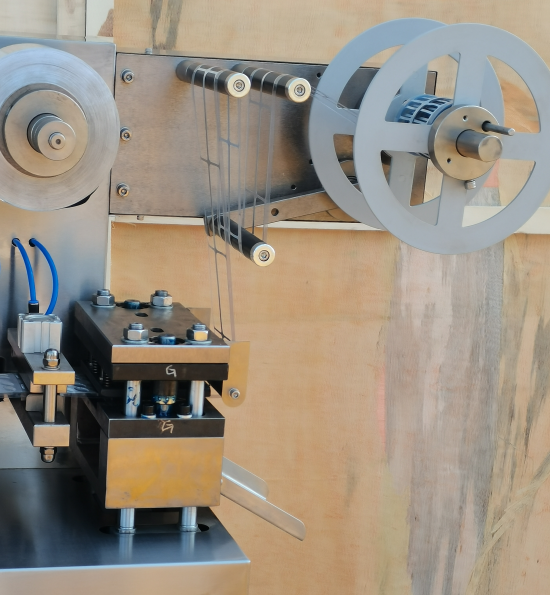

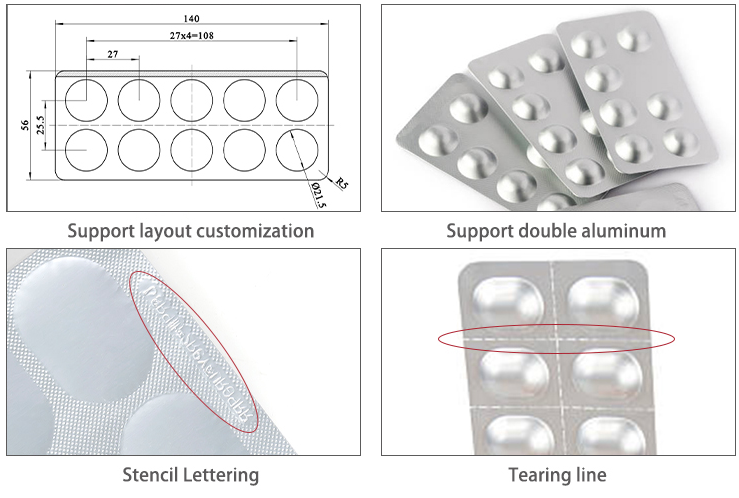

Flat panel blister packaging machine consists of bottom film transfer station, bottom film heating station, blister molding station, wrapped product loading station, cover film transfer station, cursor positioning station (optional), heat sealing station, tearing line station (optional), haul-off station, cutting station, waste rewinding station (optional). According to the process can be summarized as follows:

1.) parameter setting: according to the molding and production capacity needs to first enter the packaging parameters in the computer;

2.) Blister formation: After the equipment is started, the bottom film is transferred on the working platform driven by the "traction station", while the bottom film is formed into a blister under the action of the "bottom film heating station" and "blister forming station". At the same time, the bottom film forms the blister space under the action of "bottom film heating station" and "blister molding station";

3.) product loading: according to the nature and state of different materials with the appropriate loading system, so that the product lay flat in the blister;

4.) Blister heat sealing: the cover film is laminated with the bottom film in the transmission process, and the blister is sealed under the action of "heat sealing station";

5.) finished product cutting: blister heat sealing in the knife cutting, finished products through the discharge port collection.

3. Applications

Flat plate blister packaging machine is suitable for packaging some flat or thin products, such as electronic components, medicals, food, cosmetics and so on. It can carry out automatic and high-quality packaging for these products, improve production efficiency, reduce costs and improve product quality. The specific scope of application includes:

1.) Medical industry: capsules, tablets, vials, ampoules, etc.

2.) daily chemical: cream, liquid oil, solid, powder daily chemical products, etc.

3.) Electronic cigarettes: cartridges, atomizers, etc.

4.) Foodstuffs: honey, lollipop, seasoning, jam, edible oil, etc.

5.) medical devices: surgical instruments, small instruments, Chinese medicine instruments, medical polymer materials and products, etc.

6.) Electronic Components: electronic components, capacitors, transistors, etc.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)