Doypack premade pouch packing machine

Doypack premade pouch packing machines represent a form of machinery that automatically packages a diverse array of goods, typically employed to fill products into pre-made bags and seal them. Pouch packaging machines find extensive use across multiple industries. Their benefits, including streamlining production processes, adaptability, maintaining product freshness, effective material utilization, and automation, establish them as essential and pivotal equipment within manufacturing facilities. These machines are instrumental in enhancing production efficiency, guaranteeing top-notch packaging, and aligning with the demands of modern manufacturing standards.

Product Application:

- Food Industry: doypack premade pouch packing machine are widely used in the food industry, including packaging nuts, dried fruits, puffed foods, frozen foods, condiments, beverage powders and other food products.

- Pharmaceutical Industry: Used for packaging medicines, health products, medical devices and other pharmaceutical related products.

- Cosmetics Industry: Suitable for packaging cosmetics, skin care products, shampoo, shower gel and other beauty products.

- Daily Necessities Industry: Used for packaging washing powder, detergent, hand sanitizer and other daily necessities.

- Agricultural Industry: Suitable for packaging seeds, fertilizers, agricultural products, etc.

Product Advantages

- Streamlined Production: These machines automate packaging processes, boosting productivity and output.

- Versatility: Capable of packaging a wide range of products, suitable for diverse industries.

- Freshness Preservation: Sealing capabilities maintain product freshness and prolong shelf life.

- Material Efficiency: Precise filling and sealing reduce waste, leading to cost savings and sustainable practices.

- Automation: Reducing manual labor, enhancing consistency, and improving operational efficiency.

- Increased Productivity: Optimizing packaging workflows, minimizing downtime, and enhancing productivity.

- Quality Assurance: Ensuring consistent and reliable packaging for superior product quality and customer satisfaction.

- Customization: Tailoring machines to meet specific packaging needs, providing flexibility for various products.

- Cost-Effectiveness: Investing in these machines can lead to long-term savings through improved efficiency and reduced packaging costs.

- Meeting Industry Demands: Essential for fulfilling modern manufacturing requirements, ensuring competitiveness in the market.

How to use Doypack premade pouch packing machines:

- Machine Setup: Ensure the machine is properly set up and calibrated according to the specific requirements of the product being packaged. Check that all components are in working order, including the filling mechanism, sealing unit, and controls.

- Material Preparation: Load the pre-made pouches onto the machine's pouch feeding system. Prepare the product to be filled into the pouches, ensuring it is ready for the packaging process.

- Adjust Settings: Set parameters such as filling volume, sealing temperature, and speed based on the product specifications. Make any necessary adjustments to optimize the packaging process.

- Start the Machine: Initiate the machine to begin the packaging process. Monitor the machine's operation to ensure smooth and efficient packaging.

- Filling and Sealing: The machine will automatically fill the pre-made pouches with the product. The filled pouches will then move to the sealing station where they are sealed to ensure product freshness and security.

- Quality Check: Periodically inspect the filled and sealed pouches to ensure they meet quality standards. Address any issues or defects promptly to maintain product integrity. End of Operation: Once the desired quantity of pouches is filled and sealed, stop the machine. Clean the machine thoroughly to prepare for the next production run.

- Maintenance: Regularly maintain the machine by cleaning and lubricating components as recommended by the manufacturer. Conduct inspections to identify and address any routine potential issues to ensure optimal performance.

It is crucial to follow the manufacturer's instructions and guidelines for the specific Doypack premade pouch packing machine being used to ensure safe and efficient operation.

Our packaging machine range includes:

VFFS machine VS Vertical form fill Seal machine:

- Granule VFFS Packing Machine.

- Powder VFFS Packing Machine.

- Liquid VFFS Packing Machine.

Flow wrapping machine VS pillow packing machine:

- Up Paper Flow Packing Machine.

- Down Paper Flow Packing Machine.

- Four Side Sealing Flow.

- cookie/cake/popsicle Packing Machine.

- Heat Shrink Packaging Machine.

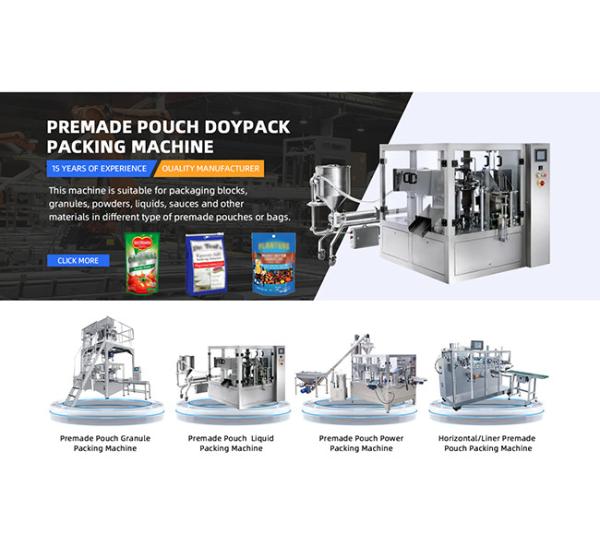

pouch packing machine VS doypack packaging machine:

- Granule Doypack Packing Machine.

- Powder Doypack Packing Machine.

- Liquid Doypack Packing Machine.

- Rotary Premade Pouch Packing Machine.

- Horizontal/Liner Premade Pouch Packing Machine.

Automatic packaging line solution

- weight inspection machine

- metal inspection machine

- robot carton packing system

- carton sealing machine

- coding machine

- robot palletizing system

Our packaging machines can be used to package the following foods:

nut,driedfruits,bakerycandy.sugar,food/dumplingproducts,cookie,cake,bread.frozensnack,chocolate,chips,marshmallow,confectionery.popsicle,candy bars,ice cream bars,brownies,muffins, nooddles,etc.

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we provide quality products at factory price, welcome to visit us!

Q2: If we buy your machine, what quality guarantee or warranty do you provide?

A2: We provide you with high-quality machines with a 3-year warranty and provide lifetime technical support.

Q3: When can I get the machine after payment?

A3: The delivery time is subject to the exact machine you confirmed

Q4: How do you provide technical support?

A4:1. Provide technical support via phone, email or MSN/Skype 24/7

2.Provide you with instructions/videos for machine installation, adjustment, setting, maintenance.

3. Engineers are available to provide services for overseas machinery

Q5: How does your after-sales service work?

A5: Ordinary machines will be properly adjusted before shipment. You can use the machine immediately. You can also get free training advice on our machines in our factory. You can also get free advice and consultation, technical support and service, and lifetime technical support via email/fax/phone.

Q6: How about spare parts?

A6: After we handle everything, we will provide you with a spare parts list for your reference

Q7: If we have very special requirements for the production line, can you help me with the design?

A7: Customized design is available with experienced mechanical engineers

Q8: If we have samples of new products, can you help analyze and design the machine?

A8: Yes, our technical department can help analyze, design and test the new products you provide.

Q9: Can you tell me how to start an order?

A9: After paying a 30% deposit to our company after signing the contact information (Pl). We arrange production. Test and inspect the machine before shipment.

Checked by customers or third-party agencies through online or on-site testing. Send the balance before shipment

Q10: Can you send me the product catalog and price list?

A10: An electronic catalog showing product styles is available for your reference. Since the prices of specific products vary, please consult us for your detailed products

Q11: Can l visit your factory?

A11: Sure, Our factory address: Room 304,Wanchuangfang, No.155 Anzhi Road, Jiading District,Shanghai,China