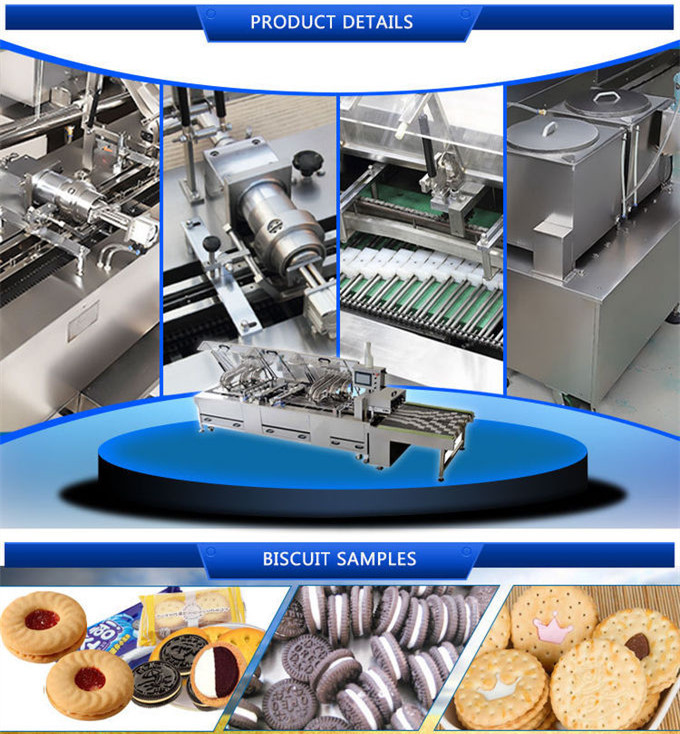

New Product High Speed Full Automatic Cookie Biscuit Flow Packing Processing Line

Siemens Brand PLC control system

Full stainless steel structure

Fast speed Max. 350bags per minute.

Sorting&Feeding conveyor

Main Feeding Conveyor Dimension:7000mm x 600mm width

Inlcuding: 3 sets sorting conveyor

Door slot plate

Door pushers 2sets, 4units Delta Servos controlled

Food grade PU belt 1.2mm thickness

SK-320 Packing Machine $6,000.00

Ø A date printer included,

Ø Standard conveyor belt length 2540mm, side with stacking support.

Ø Photo cell

Ø With Middle plastic brush and belt.

Ø Packing speed: 30-350bag/min

Ø Bag size: L (80-240) x W (35-165) x H (5-55) mm

Ø Max wid th of the packing film: 380mm

Ø Packing film thickness: 0.03-0.07mm

Ø Total power/voltage: 5KW/Single 220VAC/50Hz

Ø Machine Size: 4200 x 1100 x 1700 mm (L x W x H)

Ø Machine weight: 650 kg

Ø One set Spare parts.

Plastic push: 5pcs, Inner turret spanner: 1set,

Monkey wrench: 1set, Screwdriver: 1 set

Biscuit ice cream and chocolate sandwich machine

Sandwiching speed: 100-500pcs/min(sandwich biscuit)

Weight: approx 650kgs

Dimension: 4700x1500x1500mm

For option:

Single lane (2+1) biscuit sandwiching machine

Single lane Two color (2+1) biscuit sandwiching machine

Double lanes (2+1) biscuit sandwiching machine

Single lane (3+2) biscuit sandwiching machine

Four lanes (2+1) biscuit sandwiching machine

Our Services

Pre-Sales Service After-Sales Service

* Inquiry and consulting support. * Training how to instal the machine.

* Training how to use the machine.

* View our Factory. * Engineers available to service machinery overseas.

Pre-Sales Service

* Inquiry and consulting support.

* Any time welcome to view our factory.

* Bring your sample test in our machine.

* Check the quality and device.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Provide the solution within 2 hours.

* Engineers can speaking english to help.

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

If you are interested in the machine, please feel free to contact us, we will provide professional information and provide a suitable proposal for you.