Certification :

CE , ISO, CE, SGS

Supply Ability :

10 Set/Sets per Month Biscuit Baking Oven

Packaging Details :

The machine shall be packaged by wooden cases,which are suitable for long distance transportation and seaworthy.

Applicable Industries :

Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops, automatic biscuit machine

After Warranty Service :

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location :

Canada, Italy, Brazil, Mexico, South Korea, Sri Lanka

Showroom Location :

Canada, United States, Brazil, Russia, Morocco, Argentina, Algeria, Bangladesh, South Africa

Video outgoing-inspection :

Provided

Machinery Test Report :

Provided

Marketing Type :

New Product 2020

Warranty of core components :

1 Year

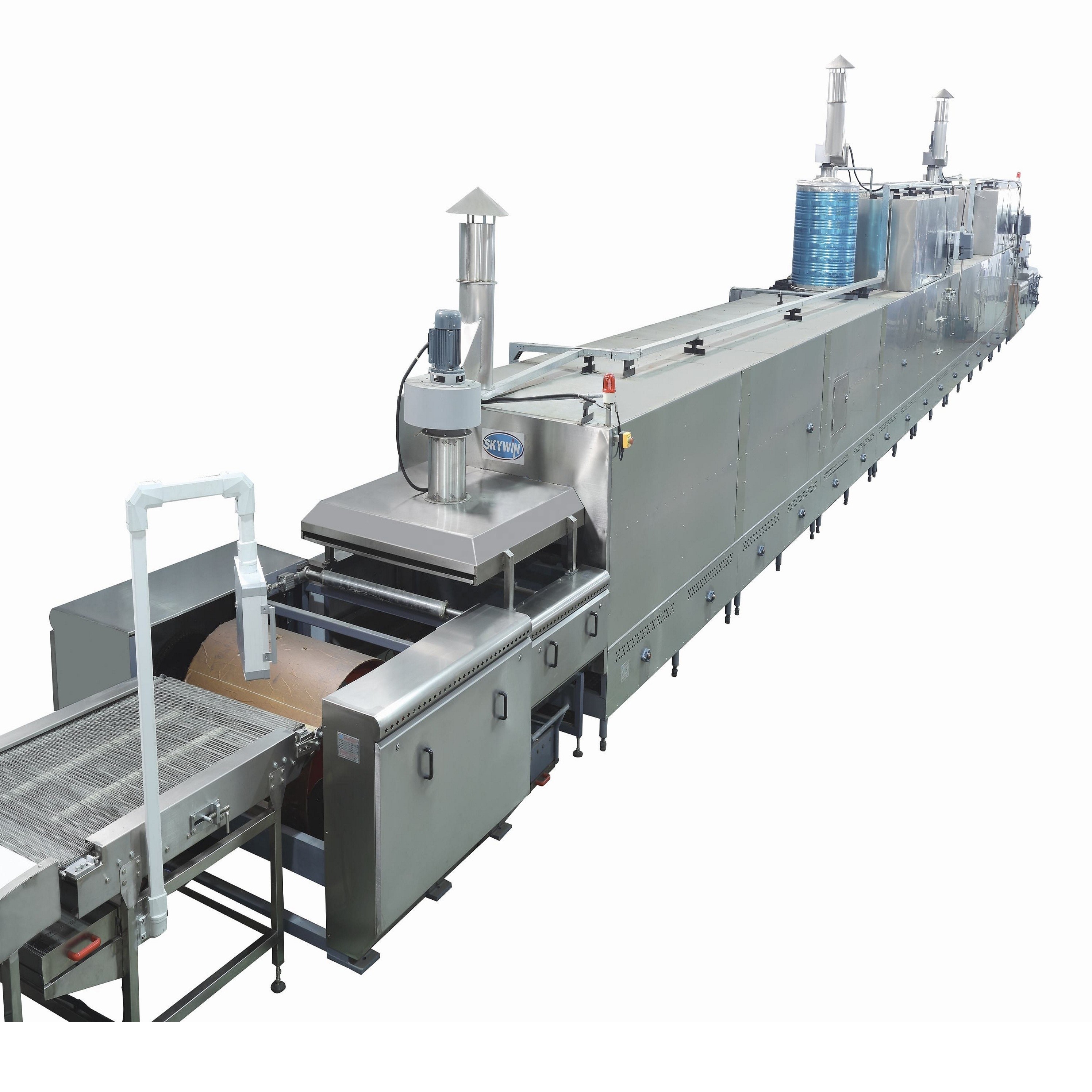

Core Components :

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump, The Whole Line

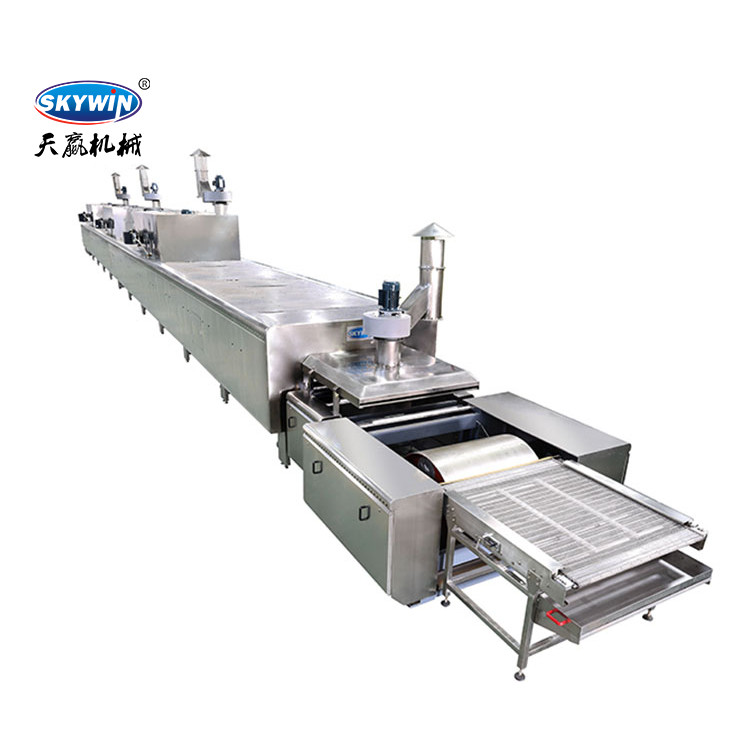

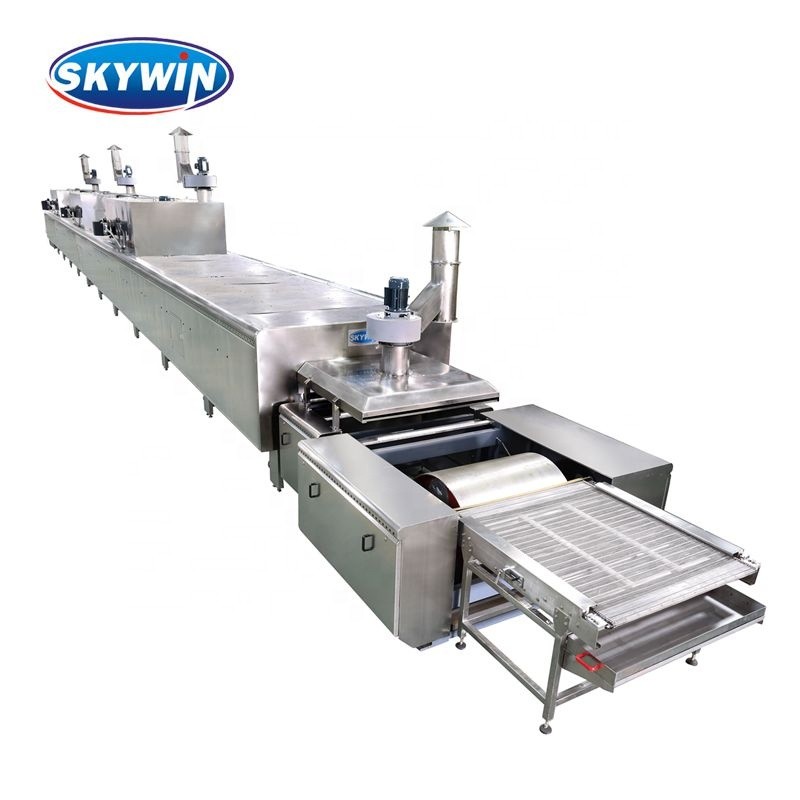

Dimension(L*W*H) :

1900*1350*800mm

After-sales Service Provided :

Field installation, commissioning and training

Application fields :

Vegetable processing plant, Winery, Cannery, Flour mill, Commercial catering, Cooking oil factory, Meat processing plants, Seasoning plant, Dairy products factory, Fruit processing plant, Bakery, Snack food factory, Frozen food Factory, Beverage Factory

Machinery Function :

biscuit making machine

Raw material :

Milk, Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Water

Output product name :

Hard and Soft Biscuit

Key Selling Points :

Multifunctional

Materials :

Stainless steel 304#

Conveyor belt :

Cotton and PU

Motor :

Chinese famous brand GUOTAI

After-sales Service :

Service Machinery Overseas

Automatic :

Touch Screen Control

Air Cylinder :

AirTAC Brand