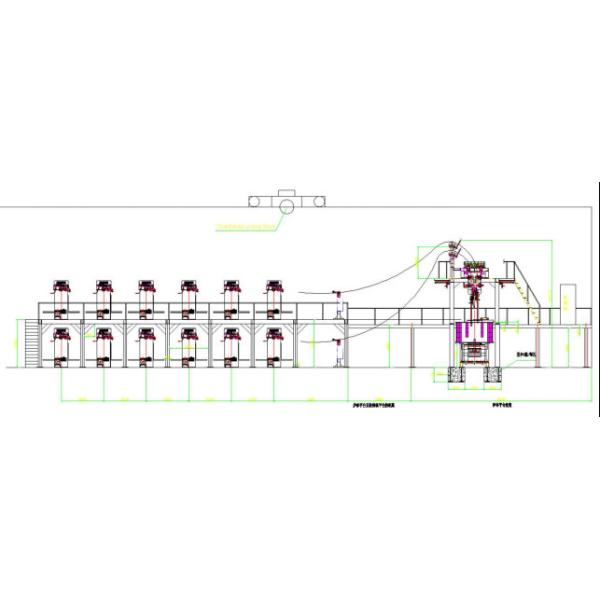

Copper Wire Upward Casting Machine CCR Line 500 Type Three Body Furnace

Feature

1. The gapless connecting expansion sleeve is used for the traction device, the PLC is used to control the servo motor correctly, and to assure that each order from the PLC is correct and accurate.

2. The paperless recorder is used and is connected to the manager’s computer. All the temperature records within one month can be checked, through which the controlling of the furnace temperature can be more effective and the rod quality can be increased. (chose when the buyer need)

3. The thickness of the furnace is increased, e.g., the furnace for 5000 type is 1.6 meters which is having a better heating preservation effect.

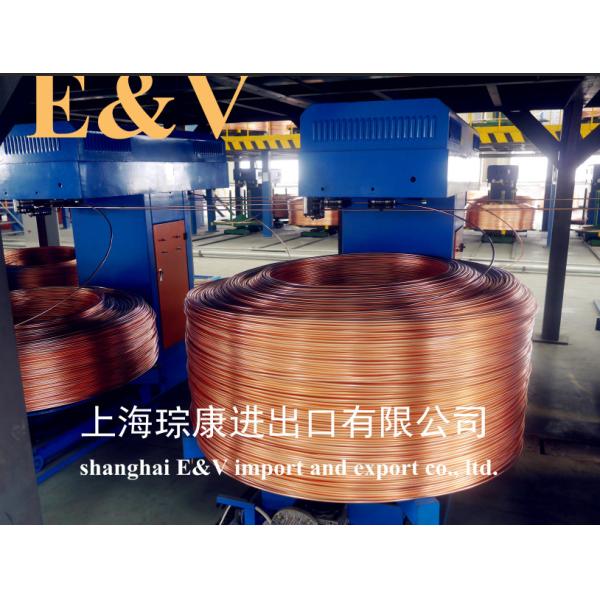

The upcasting line (unit for shot as here below) is used to produce the long and bright oxygen-free copper rod. The induction melting furnace melt the copper cathode into liquid, the liquid keeps off the air by charcoal or graphite flake in case of be oxidation. The holding furnace keeps the copper liquid temperature in 1150℃±10℃, the casting machine crystallizes the copper liquid in crystallizer quickly, then continuously produces copper rod, then the final product will be finished through the double head take up machine and other accessory equipment.

Main Technology Parameter For Copper Rod Up-casting Machine1

| | 2000MTΦ8mm→Φ14.4mm | 2000MTΦ17mm→Φ30mm | 3000MTΦ8mm→Φ14.4mm |

| Main para-meter | 1 | Model: SYJ0408-I2 | Model: SYJ0417-I2 | Model: SYJ0608-I3 |

| 2 | Yearly capacity:2000mt | Yearly capacity:2000mt | Yearly capacity:3000mt |

| 3 | Furnace structure:300type two- body furnace(1melting furnace,1 holding furnace) | Furnace structure:300type two- body furnace(1melting furnace,1 holding furnace) | Furnace structure:300type three- body furnace(2melting furnace,1 holding furnace) |

| 4 | Casting strands:4 | Casting strands:4 | Casting strands:6 |

| 5 | Casting rod diameter : Φ8mm→Φ14.4mm | Casting rod diameter : Φ17mm→Φ30mm | Casting rod diameter : Φ8mm→Φ14.4mm |

| 6 | casting speed:0~3000mm/min | casting speed: 0~1000mm/min | casting speed: 0~3000mm/min |

| 7 | annual working time:7920h | annual working time:7920h | annual working time:7920h |

| 8 | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm |

| 9 | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm |

| 10 | Copper melting velocity:260kg/h | Copper melting velocity:260kg/h | Copper melting velocity:380kg/h |

| 11 | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton |

| 12 | Take-up form: frequency automatic adjust | Take-up form: automatic adjust | Take-up form: frequency automatic adjust |

| 13 | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling | Take-up plate driven approach: pushed by copper rod,manual adjusting | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling |

| 14 | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist |

| 15 | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet |

| 16 | Rod clamping method:air clamping | Rod clamping method: manual clamping | Rod clamping method:air clamping |

| 17 | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen |

| 18 | Total power:150KW AC three-phase 380V | Total power:150KW AC three-phase 380V | Total power:200KW AC three-phase 380V |

| | | | |

| Price | | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) |

Main Technology Parameter For Copper Rod Up-casting Machine2

| | 3000MT Ф17mm→Ф30mm | 5000MT Ф8mm→Ф14.4mm | 5000MT Ф17mm→Ф30mm |

| Main Para-meter | 1 | Model: SYJ0617-I3 | Model: SYJ1008-I3 | Model: :SYJ1017-I3 |

| 2 | Yearly capacity:3000mt | Yearly capacity:5000mt | Yearly capacity:5000mt |

| 3 | Furnace structure:300type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:300type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:300type three- body furnace(2melting furnace,1 holding furnace) |

| 4 | Casting strands:6 | Casting strands:10 | Casting strands:10 |

| 5 | Casting rod diameter : Ф17mm→Ф30mm | Casting rod diameter : Ф8mm→Ф14.4mm | Casting rod diameter : Ф17mm→Ф30mm |

| 6 | casting speed:0~1000mm/min | casting speed:0~3000mm/min | casting speed:0~1000mm/min |

| 7 | annual working time:7920h | annual working time:7920h | annual working time:7920h |

| 8 | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm |

| 9 | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm |

| 10 | Copper melting velocity:380kg/h | Copper melting velocity:650kg/h | Copper melting velocity:650kg/h |

| 11 | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton |

| 12 | Take-up form: automatic adjust | Take-up form: frequency automatic adjust | Take-up form: automatic adjust |

| 13 | Take-up plate driven approach: pushed by copper rod,manual adjusting | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling | Take-up plate driven approach: pushed by copper rod,manual adjusting |

| 14 | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist |

| 15 | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet |

| 16 | Rod clamping method:manual clamping | Rod clamping method:air clamping | Rod clamping method: manual clamping |

| 17 | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen |

| 18 | Total power:200KW AC three-phase 380V | Total power:240KW AC three-phase 380V | Total power:240KW AC three-phase 380V |

| | | | |

| Price | | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) |

Main Technology Parameter For Copper Rod Up-casting Machine3

| | 8000MTФ8mm→Ф14.4mm | 8000MTФ17mm→Ф30mm | 10000MTФ8mm→Ф14.4mm |

| Main para-meter | 1 | Model :SYJ1608-I3 | Model :SYJ1617-I3 | Model :SYJ2008-I3 |

| 2 | Yearly capacity:8000mt | Yearly capacity:8000mt | Yearly capacity:10000mt |

| 3 | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) |

| 4 | Casting strands :16 | Casting strands :16 | Casting strands :20 |

| 5 | Casting diameter: Ф8mm→Ф14.4mm | Casting diameter: Ф17mm→Ф30mm | Casting diameter: Ф8mm→Ф14.4mm |

| 6 | Casting speed:0~3000mm/min | Casting speed :0~1000mm/min | Casting speed:0~3000mm/min |

| 7 | annual working time:7920h | annual working time:7920h | annual working time:7920h |

| 8 | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm |

| 9 | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm |

| 10 | Copper melting velocity:1020kg/h | Copper melting velocity:1020kg/h | Copper melting velocity:1270kg/h |

| 11 | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton |

| 12 | Take-up form: frequency automatic adjust | Take-up form: automatic adjust | Take-up form: frequency automatic adjust |

| 13 | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling | Take-up plate driven approach: pushed by rod, manual adjusting | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling |

| 14 | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist |

| 15 | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet |

| 16 | Rod clamping method: air clamping | Rod clamping method: manual clamping | Rod clamping method: air clamping |

| 17 | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen |

| 18 | Total power:400KW AC three-phase 380V | Total power:400KW AC three-phase 380V | Total power:500KW AC three-phase 380V |

| | | | |

| Price | | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) |

Main Technology Parameter For Copper Rod Up-casting Machine4

| | 10000MTФ17mm→Ф30mm | 12000MTФ8mm→Ф14.4mm | 12000MTФ17mm→Ф30mm |

| Main para-meter | 1 | Model :SYJ2017-I3 | Model :SYJ2408-I3 | Model :SYJ2417-I3 |

| 2 | Yearly capacity:10000mt | Yearly capacity:12000mt | Yearly capacity:12000mt |

| 3 | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) | Furnace structure:500type three- body furnace(2melting furnace,1 holding furnace) |

| 4 | Casting strands:20 | Casting strands:24 | Casting strands:24 |

| 5 | Casting diameter: Ф17mm→Ф30mm | Casting diameter: Ф8mm→Ф14.4mm | Casting diameter: Ф17mm→Ф30mm |

| 6 | Casting speed :0~1000mm/min | Casting speed 0~3000mm/min | Casting speed 0~1000mm/min |

| 7 | annual working time:7920h | annual working time:7920h | annual working time:7920h |

| 8 | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm | Liquid tracking precision:±2mm |

| 9 | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm | Take-up coil standard: φ700mm×φ1500mm×800mm |

| 10 | Copper melting velocity:1270kg/h | Copper melting velocity:1520kg/h | Copper melting velocity:1520kg/h |

| 11 | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton | Copper melting power consumption:<350kwh/ton |

| 12 | Take-up form: automatic adjust | Take-up form: frequency automatic adjust | Take-up form: automatic adjust |

| 13 | Take-up plate driven approach: pushed by rod ,manual adjusting | Take-up plate driven approach: PLC control, frequency adjust,automatic coiling | Take-up plate driven approach: pushed by rod ,manual adjusting |

| 14 | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist | Material feeding method:whole piece of electrolytic copper cathode fed by electric hoist |

| 15 | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet | Upward driven approach:driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet |

| 16 | Rod clamping method: manual clamping | Rod clamping method: air clamping | Rod clamping method: manual clamping |

| 17 | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen | Operation interface:date display,servo motor controlled by touch screen |

| 18 | Total power:500KW AC three-phase 380V | Total power:600KW AC three-phase 380V | Total power:600KW AC three-phase 380V |

| | | | |

| price | | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) | A price: price negotiable AA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling ) AAA price: price negotiable (updates price A: 1.change the brand of electrical panel to Siemens,2.stepless automatic temper controlling, 3.full-automatic feeding devise) |

Unit instructions for furnace

The line frequency induction furnace includes furnace body ,furnace frame and inductor.

The shell of the furnace is made of welded steel, inside part is made of casted refractory brick and quarts sand. Furnace frame is used for propping up the whole furnace, it is fastened on the foundation by ground bolt, inductor composed of coil, water jacket, iron core and copper channel.The high voltage side of the inductor(primary)includes coil with cooling water, the voltage could be adjusted form 90V-420V(holding furnace is 90V-380V), the low voltage side of the inductor(secondary)includes short circuited copper channel, after electrifying, it will produce big current in copper channel with the action of electromagnetism induction, and melt the copper channel and also melt the cathode at the same time .

Water jacket and coil all need to be cooled by water, the water can be recycling used, and is supplied by the cooling water system.

Welome to contact us