Tank With Biofiltration+ SBR Biological Contact Oxidation+ MBR Filtration Sewage Treatment

Product Description

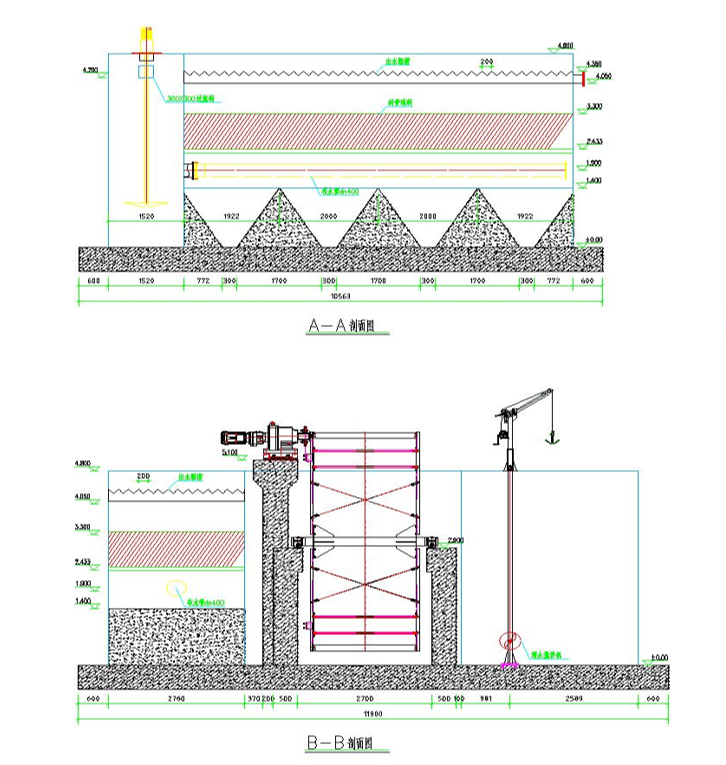

The SABR process integrates the biofilm method and the activated sludge method. On the one hand, a large amount of biofilm grows on the inner surface of the runner, which has the characteristics of the biofilm method. On the other hand, there are bacterial micelle growth in the pool outside the runner. The good environment. Therefore, the SABR process has the characteristics of both the biofilm process and the activated sludge process.

For sewage treatment with a scale of 500t/d or more, it adopts the form of enamel assembly tank, which is beautiful and compact. The main structure of the enamel tank is assembled by high-strength steel plate (ART310, 455MPa), special sealant, self-locking bolts and other materials. The enamel coating thickness of the enamel assembly board is 200-300um, one layer of glaze, one layer of glaze, and two layers are fired. In places with low temperature, an insulation layer can be made according to user needs.

Product Features

1. Small footprint: the integrated structure design is adopted, the units with different processing functions are concentrated in the same reactor, and the footprint is less than 0.8m2/(m3·d);

2. Short construction period: The main process system can adopt the formal form of equipment and enamel tanks, and it can be used when the pipeline is connected to the factory. The construction period can be controlled within 45 days;

3. Convenient management: Cloud control technology can realize remote monitoring and control of various process equipment, and can realize unattended operation.

Product Advantages

1. Ensure the quality of the effluent, and the effluent can meet the discharge requirements of Class B or Class A

2. Save 55% of your energy consumption and reduce operating costs

3. Reduce your footprint by 48%

4. Save you more than 30% of construction costs

Applications

Hotel, restaurant,sanatorium,hospital

Small village/town Station, airport, port

Factory , mining , military camp,scenic spots

Industrial organic wastewater similar

Product Model

| Technical Parameter |

| Model | 0.5 | 1 | 3 | 5 | 10 | 20 | 30 |

| Capacity (m3/h) | 0.5 | 1 | 3 | 5 | 10 | 20 | 30 |

| Air blower | Model | KY-0.75 | KY-1.1 | KY-1.2 | KY-4.4 | KY-8.8 | KY-11.5 |

| Power | 0.75 | 1.1 | 1.2 | 4.4 | 8.8 | 11.5 |

| Pump | Model | 40QW-10-0.75 | 40QW-10-7-0.75 | 50QW10-10-1.1 | 50QW25-7-1.5 | 50QW25-7-1.5 | 50QW42-9-2.2 |

| Power | 0.75-1.1 | 1.5 | 2.2 |

| Floor space | 4.5 | 6.5 | 12 | 15 | 35 | 51 | 76 |

| Inlet water | 150-400 |

| Outlet water | 20-30 |

FAQ

Q: What parameters do I need to provide for the inquiry?

A: Please inform the source of the sewage, water quality, flow rate, operating time, slot opening size(for the filter), total sludge (for the dewatering machine), we will choose the appropriate model and price for you.

Q: Do you offer after-sales service?

A: Yes. Engineers with more than ten years of after-sales experience will be dedicated to serve you.

Q: How long is your warranty?

A: One year after the arrival of the goods. During this period, any damage caused by non-human factors, we will send the damaged parts free of charge.

Q: Do you provide OEM service?

A: Yes, Any required logo is available.

Q: What certificates do you have?

A: ISO/CE/SGS.

Q: Can you meet my special requirements for my products?

A: Yes, we have a professional design team. We can provide drawings and design plan according to your requirements.