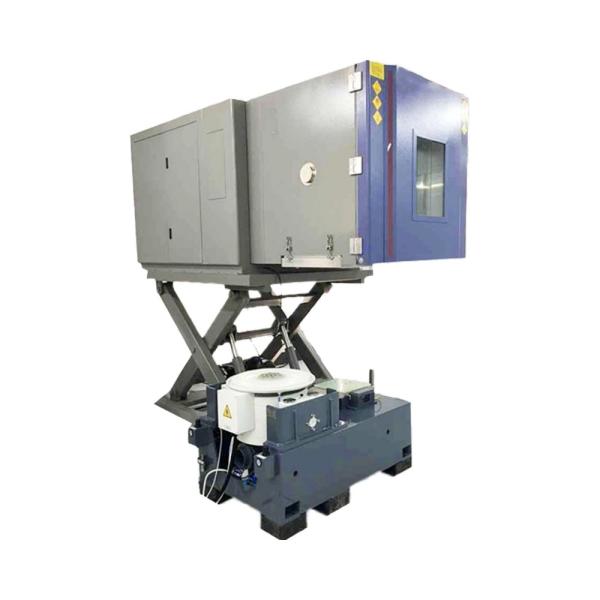

In the realm of military operations, the reliability and performance of military communication equipment are of paramount importance. The Custom Vibration Table combined with a Temperature Humidity Test Chamber is a specialized and sophisticated testing solution designed to meet the unique and stringent requirements of military communication gear. This integrated system enables military manufacturers and testers to subject communication equipment to a wide array of mechanical vibrations and environmental conditions, mirroring the harsh and unpredictable scenarios encountered in the field.

This advanced testing system is meticulously crafted for military communication equipment, including but not limited to radios, satellite communication devices, encrypted communication systems, and tactical communication headsets. The primary objective is to evaluate how these devices perform and endure under the combined stress of mechanical vibrations and temperature - humidity variations. By replicating real - world situations such as vibrations during transportation in armored vehicles, aircraft, or ships, and exposure to extreme temperatures and humidity levels in diverse terrains and climates, manufacturers can identify potential weaknesses in the design, enhance product quality, and ensure seamless communication in critical military operations.

- Tailored Vibration Capabilities

- The custom vibration table is engineered to generate a wide range of vibration frequencies, typically adjustable from 1 Hz to 2000 Hz. This broad spectrum allows for the simulation of various types of vibrations that military communication equipment may encounter. For example, low - frequency vibrations can mimic the rumbling of a military vehicle on rough terrain, while high - frequency vibrations can represent the shockwaves from nearby explosions. The vibration amplitude is precisely controllable, with a range of 0.1 mm to 100 mm (peak - to - peak), enabling the reproduction of different levels of vibration intensity.

- One of the key features of the custom vibration table is its ability to generate vibrations in multiple axes. Military communication equipment often experiences complex multi - directional forces. The table can generate vibrations in vertical, horizontal, and rotational axes, providing a more realistic simulation of the actual mechanical stresses. This multi - axis functionality is crucial for detecting potential weaknesses in the equipment's structure and internal components.

- Highly Customizable Vibration Profiles

- Operators have the flexibility to create highly customized vibration profiles based on specific test requirements. These profiles can incorporate continuous vibrations, intermittent shocks, or complex sequences that mimic the exact vibration scenarios military communication equipment is likely to face. For instance, a profile can be designed to simulate the vibrations during a military aircraft's takeoff, flight, and landing, including the vibrations caused by engine operation, turbulence, and sudden maneuvers. The ability to customize these profiles ensures that the testing is as realistic as possible, closely replicating the conditions in the field.

- Robust and Durable Construction

- Built with high - quality materials and advanced engineering, the custom vibration table is designed to withstand the rigors of continuous testing. The table's frame is constructed from heavy - duty steel, providing a stable and rigid platform for generating vibrations. The vibration - generating mechanism is engineered for long - term reliability and precision, ensuring consistent and accurate test results over extended periods. Additionally, the table is designed to handle a wide range of payloads, from small communication modules to larger, more complex communication systems.

- Extensive Environmental Simulation

- The temperature humidity test chamber integrated with the vibration table can create a wide range of environmental conditions. The temperature can be adjusted from extremely low values, such as - 50°C to simulate arctic or high - altitude military operations, to high temperatures of up to + 80°C to mimic desert or tropical combat environments. The humidity control can maintain relative humidity levels from 10% to 95%, enabling the testing of how communication equipment responds to different moisture levels. This is crucial as high humidity can cause corrosion, short - circuits, and other malfunctions in electronic components, while low humidity can lead to issues such as static electricity build - up.

- The chamber can also simulate rapid temperature and humidity transitions. In military operations, communication equipment may experience sudden changes in the environment, such as moving from a cool, dry bunker to a hot, humid outdoor area during a combat mission. The chamber can achieve temperature transition rates of up to 10°C/min and humidity transition rates of up to 5%/min, allowing for the testing of how equipment responds to these abrupt changes.

- Large and Uniform Test Volume

- The temperature humidity test chamber features a large test volume, typically ranging from 5 m³ to 30 m³, depending on the model. This spacious interior can accommodate a variety of military communication equipment, from individual handheld devices to large - scale communication consoles. The chamber is designed to provide uniform temperature and humidity conditions throughout the test volume, with temperature variations within ±1°C and humidity variations within ±5% relative humidity. This ensures that all parts of the tested equipment are exposed to the same environmental conditions, resulting in reliable and consistent test results.

- User - Friendly Interface

- The entire test system is controlled through a user - friendly interface that simplifies the operation process. The interface allows operators to easily set and adjust the test parameters for both the vibration table and the temperature humidity test chamber. It provides a clear display of the current test status, including vibration frequencies, amplitudes, temperature, humidity, and elapsed test time. The interface is designed to be intuitive, even for users with limited technical expertise, ensuring efficient and accurate testing.

- Comprehensive Data Acquisition and Analysis

- Equipped with a comprehensive data acquisition system, the test system records all relevant data during the test. This includes vibration measurements in multiple axes, temperature and humidity profiles, and any observed equipment failures or performance changes. The data can be stored in a secure database and analyzed using advanced software tools. The system can generate detailed test reports, including graphs, charts, and statistical analysis, to help engineers and military technicians understand the test results and make informed decisions.

- Remote Monitoring and Control

- Many models of this combined test system offer remote monitoring and control capabilities. This feature is particularly valuable in military applications, where testing may need to be conducted in secure or remote locations. Operators can monitor the test progress and adjust the test parameters from a remote location, such as a military command center or an off - site testing facility. This allows for continuous supervision and timely intervention, ensuring the efficiency and effectiveness of the testing process.

- Custom Vibration Table Parameters

-

| Rated Sine Force |

300kgf- 8000kg.f |

| Frequency Range |

DC-3000Hz |

| Max. Displacement p-p |

51-100mm |

| Max acceleration |

100g |

| Max. Velocity (m/s) |

2.0 |

| Max. Payload |

300-5000kg |

- Temperature Humidity Test Chamber Parameters

-

| Model |

CTHC-80 |

CTHC-150 |

CTHC-225 |

CTHC-408 |

CTHC-800 |

CTHC-1000 |

| Inside dimension(W x D x H) cm |

40 x 50 x40 |

50 x 60 x 50 |

50 x 75 x 60 |

60 x 85 x 80 |

100 x 100 x 80 |

100 x 100 x 100 |

| Outside dimension(W x D x H) cm |

95 x 140 x 95 |

105 x 150 x 105 |

105 x 165 x 115 |

115 x 175 x 140 |

155 x 190 x 140 |

155 x 190 x 160 |

| Internal material |

#304 Stainless Steel |

| External material |

Powder coated #304 Stainless Steel |

| Temperature range |

+ 150℃~ - 70 ℃ |

| Humidity range |

10% ~ 98% R. H |

| Temperature Uniformity ℃ |

0.01 |

| Humidity Uniformity % R. H. |

0.1 |

| Temperature stability ℃ |

±0.3 |

| Humidity stability % R. H. |

±2 |

| High temperature ℃ |

100 |

100 |

100 |

100 |

100 |

100 |

| Heating time (min) |

20 |

30 |

30 |

30 |

30 |

30 |

| Low temperature |

0, -40, -70 |

0, -40, -70 |

0, -40, -70 |

0, -40, -70 |

0, -40, -70 |

0, -40, -70 |

| Cooling time (min) |

20, 50, 70 |

20, 50, 70 |

20, 50, 70 |

20, 50, 70 |

20, 50, 70 |

20, 50, 70 |

| Air circulation system |

Mechanical convection system |

| Cooling system |

Imported compressor, fin evaporator, gas condenser |

| Heating system |

Sus304 Stainless steel High-speed heater |

| Humidification system |

Steam Generator |

| Humidification water supply |

Reservoir, Sensor-controller solenoid valve, recovery-recycle system |

| Controller |

Touch panel |

| Electrical power requirements |

Please contact us for requirements of specific models |

| Accessories |

Multi-layer enhanced glass window,test hole, action indicator light, case lighting barrier shelf x2 |

| Safety device |

Circuit system load protection, compressor load protection, control system load protection, humidifier load protection, overtemperature load protection, fault warning light |

- Reliability and Durability Testing

- By subjecting military communication equipment to combined mechanical vibrations and temperature humidity stress, the system helps identify potential weaknesses and failure points. This allows for the improvement of product designs to enhance reliability and durability, reducing the risk of equipment failures during critical military operations. In a combat situation, a communication breakdown can have severe consequences, and this testing system helps ensure that the equipment can withstand the harsh conditions.

- Design Optimization

- The data collected from the tests provides valuable insights into how military communication equipment responds to different conditions. Engineers can use this information to optimize product designs, such as improving the structural integrity of the equipment, enhancing the shielding of electronic components to prevent electromagnetic interference, or developing more efficient cooling systems for high - temperature environments. For example, if a radio's performance deteriorates under high - humidity and vibration conditions, the design can be modified to improve its resistance.

- Quality Control

- The system serves as a crucial tool for quality control in the military communication equipment manufacturing process. By testing equipment before it is deployed in the field, military manufacturers can ensure that it meets the strict quality standards set by the military. This helps to prevent costly equipment failures and ensures the effectiveness of military communication networks.

- Compliance Testing

- The military communication equipment industry is subject to strict military standards and regulations regarding the performance and reliability of equipment. The custom vibration table combined with the temperature humidity test chamber enables manufacturers to conduct compliance testing to ensure that their products meet these requirements. For example, military standards may specify the maximum vibration levels and temperature - humidity ranges that communication equipment must withstand.

- Stringent Manufacturing Process

- The manufacturing of this combined test system follows strict quality control procedures. Each component, from the vibration table's drive system and the temperature humidity test chamber's sensors to the control electronics and structural frame, is sourced from reliable suppliers and undergoes thorough inspection and testing. The assembly process is carried out by highly trained technicians in a clean and controlled environment. The system is calibrated and verified at multiple stages during production to ensure its accuracy and performance.

- Quality Certification and Validation

- Our test system has obtained relevant quality certifications, such as ISO standards for testing equipment and military - specific certifications. It has also been validated by independent testing laboratories to ensure that it meets industry standards and provides accurate and reliable test results. We continuously update and improve our product based on the latest technological advancements and customer feedback to maintain its high quality and performance.

- Tactical Radio Testing

- A military equipment manufacturer used the system to test a new series of tactical radios. The radios were subjected to a combination of multi - axis vibrations, extreme temperature changes, and high humidity conditions. The testing revealed that the radio's antenna connection was prone to loosening under high - vibration and low - temperature conditions. By improving the antenna's locking mechanism and using more durable materials, the manufacturer was able to enhance the radio's reliability, ensuring stable communication in the field.

- Satellite Communication Terminal Testing

- A defense contractor utilized the system to test a satellite communication terminal. The terminal was exposed to a variety of vibration and temperature humidity conditions to simulate the harsh environment of space and ground - based operations. The testing showed that the terminal's electronic components were sensitive to high - humidity and rapid temperature transitions, which could lead to system failures. By improving the component's packaging and adding thermal management systems, the contractor was able to improve the terminal's performance and reliability, ensuring seamless communication for military satellite networks.

- Combat Helmet Communication System Testing

- A company manufacturing combat helmet communication systems used the system to test the durability and performance of its products. The systems were subjected to vibrations, temperature variations, and humidity changes to simulate the conditions they would experience during combat. The testing identified that the microphone in the helmet was prone to malfunctioning under high - humidity and high - vibration conditions. By improving the microphone's design and adding moisture - resistant coatings, the company was able to enhance the communication system's performance, providing clear and reliable communication for soldiers on the battlefield.

- Pre - Sales Technical Consultation

- Our team of military testing experts provides in - depth technical consultations to help customers understand the capabilities and suitability of the system for their specific testing needs. We offer demonstrations and training sessions to familiarize customers with the operation and functionality of the system before purchase. We also assist in selecting the appropriate test parameters and accessories based on the military communication equipment to be tested.

- After - Sales Service and Maintenance

- We offer comprehensive after - sales service, including on - site installation and commissioning. Our team of experienced technicians is available for regular maintenance, calibration, and emergency repairs. We provide genuine spare parts and timely upgrades to ensure the long - term performance and reliability of the testing system. We also offer service contracts that include preventive maintenance and priority technical support.

- Training and Technical Support

- We conduct training programs for new users to ensure they can effectively operate the testing system and interpret the test results. Our technical support team is available 24/7 to answer questions, provide troubleshooting assistance, and offer guidance on test method optimization. We also provide software updates and support for the data acquisition and analysis systems to keep the system up - to - date with the latest features and technologies.

The Custom Vibration Table combined with the Temperature Humidity Test Chamber is an essential tool for the military communication equipment industry. If you are looking to enhance the quality and reliability of your military communication equipment, this system offers a comprehensive solution. Contact us today to learn more and get a customized quotation