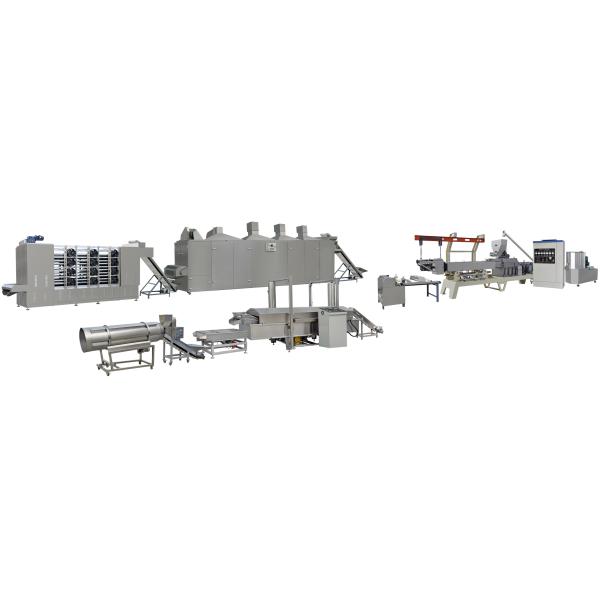

Five-Layers Roaster is used to dry a wide range of products, such as macaroni,dog snacks, corn flakes, core filling food, etc. Five layer structure can prolong the drying time and reduce the coverage area; Each layer is made of mesh belt with stainless steel; Side guard to prevent products falling from the belt; Various speed inverter drives for five layers; Auto temperature control system with the temperature range between 15-180℃; The body is well sealed to prevent any heating leakage, and thus reduce the savings in energy; Equipped with special thermal-protective coating to prevent any burnt or scald to the workers; Adjustable door hinge; flat laying mesh belt; tailor-made materials receiver Three kinds of power available: Electric, gas or oil.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)