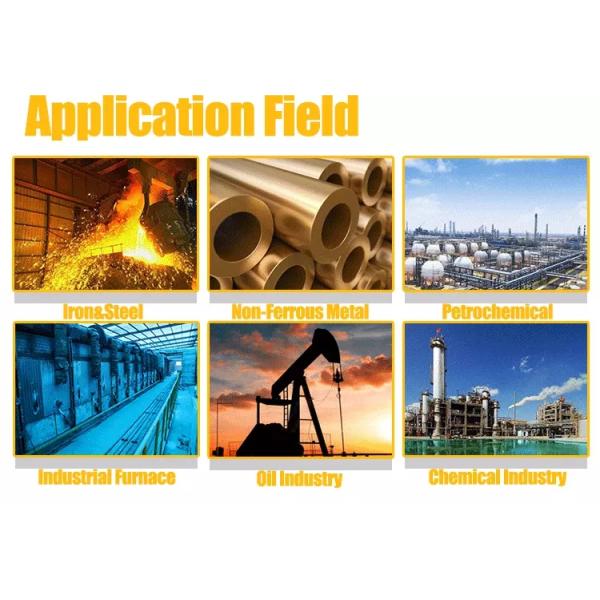

Usage for High alumina heat insulating brick/light weight high alumina insulation bricks: Light Weight high alumina poly ball insulation refractory bricks are widely used in kiln lining (not corroded by solution) and insulation layers in metallurgy, machinery, ceramics and chemical industries, which can reduce the weight of the furnace body, shorten the kiln time, reduce thermal diffusion, and protect The furnace temperature is uniform, and it can also be directly used as the lining of industrial furnaces. It is an ideal energy-saving product. Suitable for ceramic tunnel kilns, roller kilns, shuttle kilns, petrochemical reforming furnaces, conversion furnaces, metallurgical soaking furnaces, blast furnaces, hot blast furnaces, coking furnaces and other thermal equipment. Its use temperature is below 1300°C.

Application for High alumina heat insulating brick/light weight high alumina insulation bricks:

Iron&steel making industry:Blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle, tundish,heating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,annealing furnace, cupola furnace,electric arc furnace,induction furnace, AOD furnace, VOD furnace,etc thermal technology equipment. Non-ferrous Metal industry:Smelting furnace,refining furnace, reverberatory furnace,converter furnace. Building materials industry:Cement kiln,glass kiln,ceramic kiln,lime kilns,kiln car,tunnel kiln Energy & Incineration:Coke oven,general boiler,power,generation,boiler,circulating fluidized bed boiler,electric furnace,carbon rosating furnace,waste incinerators. Others:Petrochemical industry furnace.