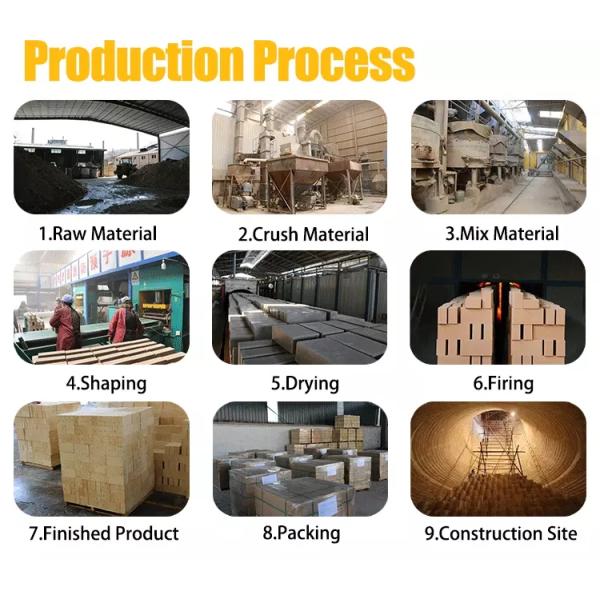

1.The corundum brick Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and Shipment

Properties of corundum bricks

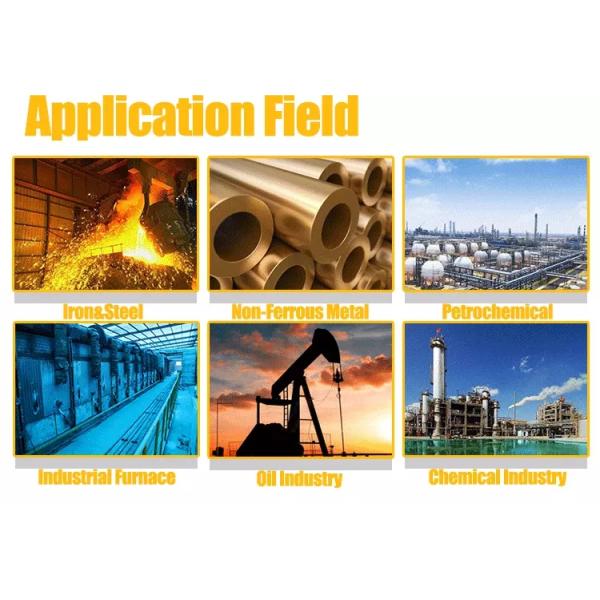

Corundum bricks are widely used in blast furnaces and hot air stoves in metallurgical industry, second-stage furnaces, gasifier, gasifier, cracking furnace, ceramic, building materials, military industry, scientific research and other industries.The corundum bricks on various kilns are subject to high temperature, high pressure, slag and strong reducing gas erosion and damage in addition to being restricted by various technological conditions.This kind of chemical erosion and structural damage to corundum bricks reduces the service life of corundum bricks.

Chemical reaction of the high temperature of alumina, alumina melting point is 2050 ℃, alumina and other oxide reaction at high temperature after the formation of the melting curve, there is a downturn in the melting temperature only chrome oxide and alumina can form a continuous solid solution, the solid melting zone between the two kinds of oxide melting point.

The main impurities in corundum bricks are silicon dioxide and iron oxide.In Al2O3 - SiO2 - FeO ternary system phase diagram, the lowest melting point is 1205 ℃, which formed in more than 1200 t can glass phase. Titanium oxide and niobium oxide can reduce the melting point of alumina products and also be the sintering AIDS.In the sintering process, alumina is mixed with titanium oxide and niobium oxide to form aluminum titanate or aluminum niobate. 1% of titanium oxide or niobium oxide is added into alumina.

Vanadium pentoxide is a low melting oxide.At low temperature, the boundary dissolution of aluminated aluminum crystals occurs and the grains are dissected.And vanadium pentoxide and CaO under oxidizing atmosphere, generate calcium vanadate of low melting point (618 ℃), under the weak reducing atmosphere generated volatile calcium vanadate. The destructive effect of vanadium pentoxide on corundum brick is to produce vanadium pentoxide precipitate between corundum grain in corundum brick, which causes cracking, and then produces structural crack and large scale flaking.

With sodium sulfide erosion of corundum brick is in the process of gas coagulation of sodium oxide in 1000 ℃ can erode corundum brick.The post-al2o3 in corundum was transformed into p-al2o3, which caused the volume of the brick to expand greatly (about 26%) and caused the corundum brick to crack and peel off the epidermis.

Na2O and SO3 under 1000 ℃ can react with sillimanite and mullite, to generate the gray stones and beta Al2O3, volume increases by about 86%, peeling, split brick.

2.The corundum brick Quality Assurance

HongTai Refractory is committed to high quality standards for all its products and services. With its thirst on State of the art technology at every level and a wide range of products, HongTai Refractory can provide ideal solutions for the stringent requirement of the customer. Backed by decade of experience in different industries, and close association with customers,HongTai Refractory will always bring new products which will give better life and value to the user.

The quality assurance system consists of the following steps:

1. Inspection and Control of incoming raw materials:According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

2. Inspection and process control:During the production, each brick weight twice to reduce weight error.

3. Inspection of product Standardization of quality of each product by process control and experimentation.

4. Taking corrective measures whenever deviations are noted.