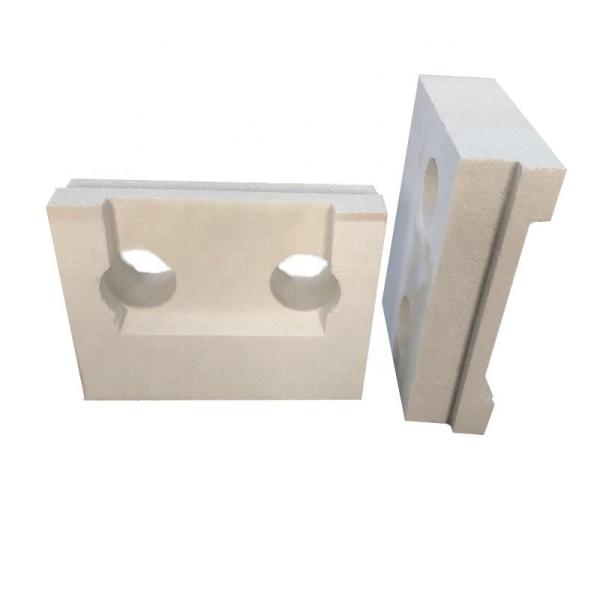

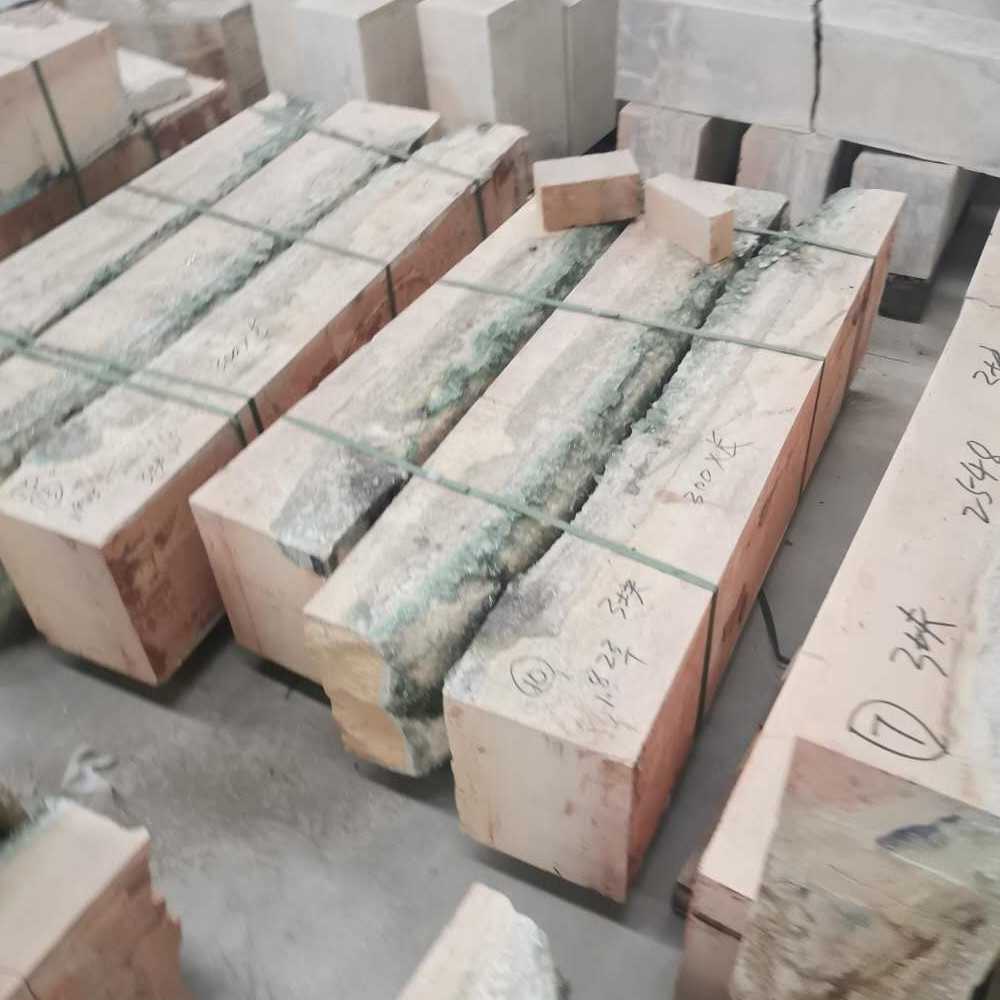

The dense microstructure of AZS33 zirconium corundum bricks makes the bricks have good resistance to glass liquid corrosion, and it is not easy to produce stones or other defects in the glass furnace. It is the most widely used product in glass kilns, and is mainly used for the upper structure of the melting pool, the pool wall and paving bricks of the working pool, and the material channel.

AZS33 is the most widely used product in the cast AZS series, and has excellent performance in preventing contamination of glass liquid. It is widely used in the wall, bottom, upper structure and feeding channel of the glass furnace.