Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

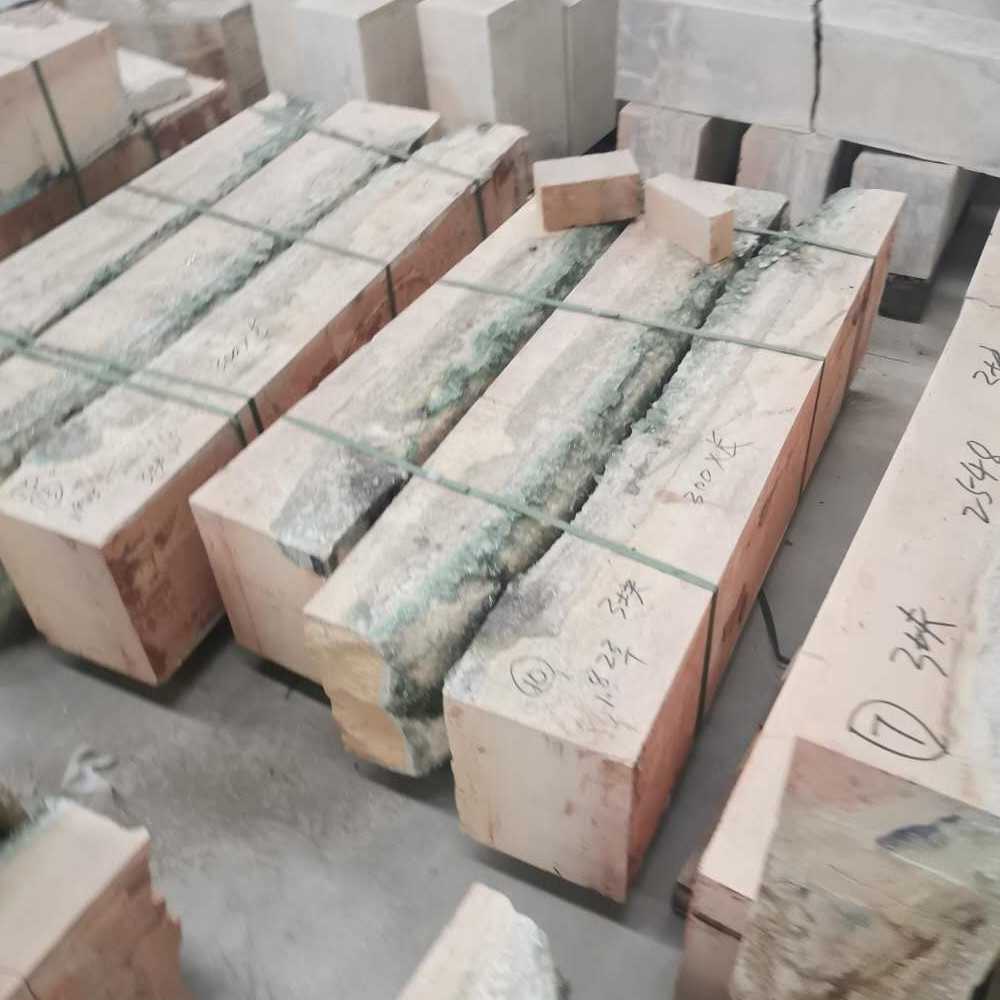

Second hand Fused Electrocast zircon corundum used bottom plate for glass melting furnace is a white solid formed by pure alumina powder and zircon sand containing 65% zirconia and about 34% silica in the electric furnace after being melted and injected into the model for cooling. Fused zirconia corundum brick is commonly known as white iron brick, also known as corundum-oblique zircon brick. The main chemical components are Al2O3 45%-50%, ZrO2 32%-44%, and SiO2 12-16%. The main mineral composition is oblique zircon (ZrO2), corundum (α-Al2O3) and glass phase. Oblique zircon crystals form the backbone of the brick, ZrO2 has a high melting point (2715°C), good chemical stability, and strong resistance to acidic and alkaline media, especially glass liquid.

Second hand Fused Electrocast zircon corundum used bottom plate for glass melting furnace is a white solid formed by pure alumina powder and zircon sand containing 65% zirconia and about 34% silica in the electric furnace after being melted and injected into the model for cooling. Fused zirconia corundum brick is commonly known as white iron brick, also known as corundum-oblique zircon brick. The main chemical components are Al2O3 45%-50%, ZrO2 32%-44%, and SiO2 12-16%. The main mineral composition is oblique zircon (ZrO2), corundum (α-Al2O3) and glass phase. Oblique zircon crystals form the backbone of the brick, ZrO2 has a high melting point (2715°C), good chemical stability, and strong resistance to acidic and alkaline media, especially glass liquid.