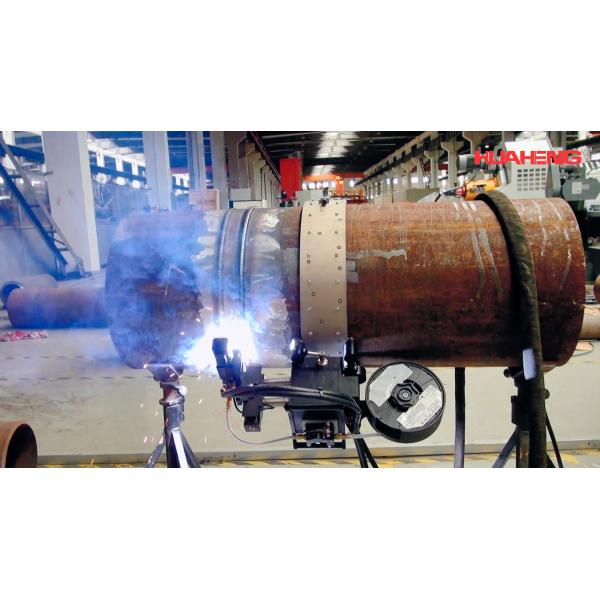

This system is a special trolley specially designed for MIG welding of pipes with super large diameters. It can weld pipes larger than φ300mm by matching the corresponding gear ring, and can realize bottom welding, filling welding and cover welding. Power supply specially designed for pipeline welding, especially suitable for engineering liquefied gas pipeline installation, oil pipeline installation and factory prefabrication.

Gear transmission mode, the rotation speed is stable and reliable; The unique MAG welding two-way bottoming welding process can meet the complex and changeable working conditions to a large extent; The double water cooling method is adopted, which is convenient for the welding process of filling and capping with large pipe diameter and large wall thickness; The integrated wire feeding system structure design ensures smooth wire feeding; Different guide rings can be selected to complete the welding of workpieces with different pipe diameters;