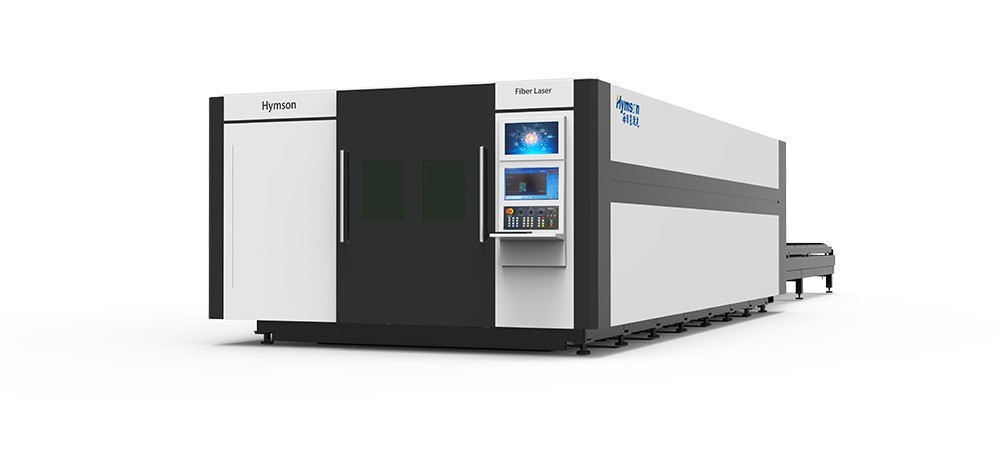

HF·TU FIBER LASER CUTTING MACHINE

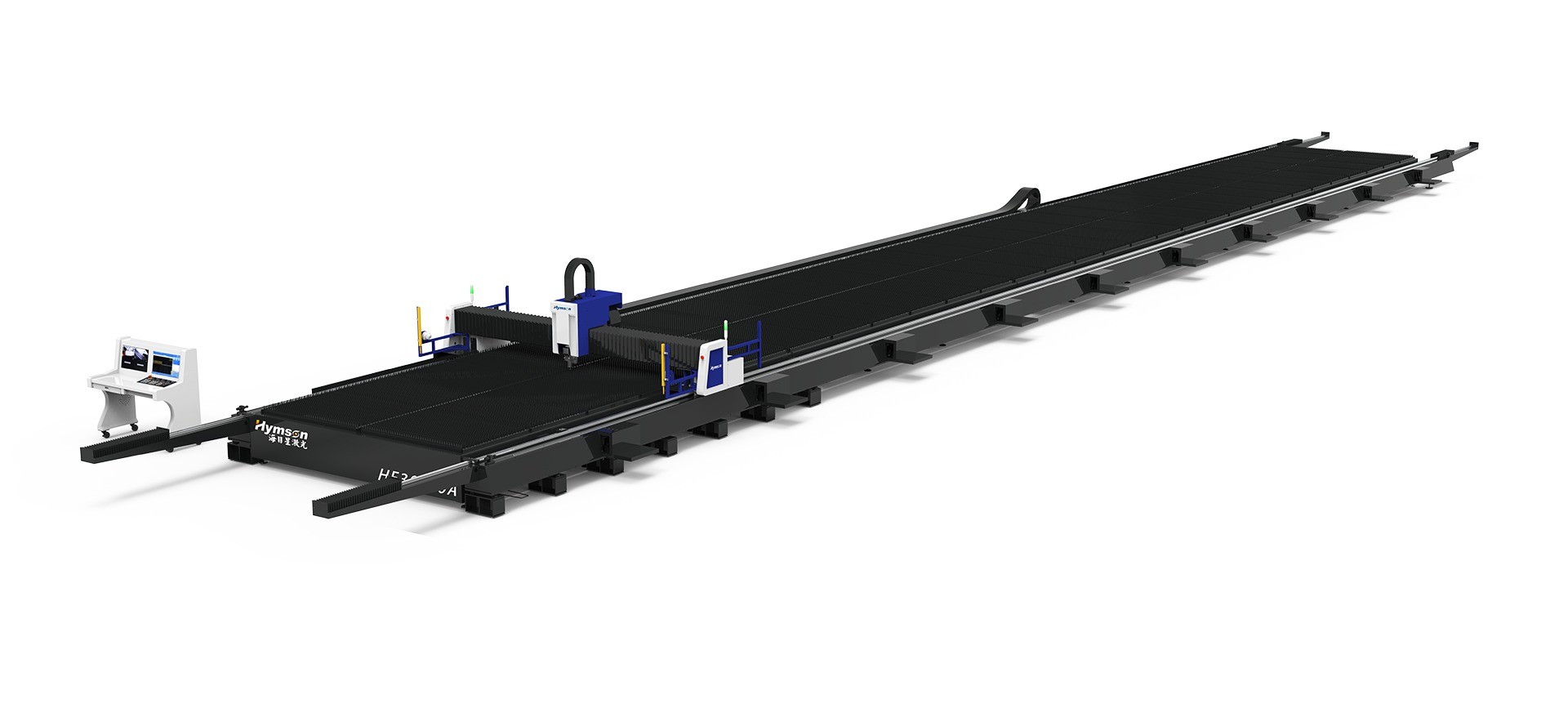

HF·TU Series steel plate cutter machine, as a brand new uncoiling feeding laser cutting machine launched by Hymson Laser, has four functions of uncoiling, feeding, cutting, and unloading.

HF·TU Series Uncoiling Feeding Laser Cutting Machine

→Know more about our cutting technology←

Uncoiling Feeding Laser Cutting Machine Realizes Uncoiling and Cutting in One

Features

1. One-stop processing

The metal plate cutting machine realizes the integrated automatic production line of uncoiling-leveling-feeding-cutting-unloading, which not only guarantees the surface quality but also guarantees the cutting speed, which greatly improves the processing efficiency of laser cutting

2. Highly intelligent cutting software

Equipped with a full-featured Master 9000 cutting software, HF·TU Series steel plate cutter machine is easy to learn and operate, highly intelligent and supports modular integration and one-touch operation.

3. Meet the diversified needs of coil processing

The metal plate cutting machine can be equipped with an automatic unloading device to perfectly combine laser cutting + automation to create a composite laser processing mode

4. Automatic unwinding and leveling equipment

The maximum load-bearing capacity is 8000kg (customizable), which can realize the net cutting of the coil material, and can automatically unwind or recycle the coil material to eliminate material wrinkles and reduce material loss

Applications

Elevator manufacturing, hardware kitchenware, chassis cabinets, electrical cabinets, hardware sanitary ware, metal utensils, machine tool sheet metal, electrical equipment, lighting hardware, advertising signs, and other thin metal coil sheet metal cutting processing applications.

Applicable material range

Pre-sale Service

2. We offer pictures, videos and other relevant documents for you to know more about the machine.

3. We are online and would respond fast to answer all your questions.

4. If you have chance visiting China, you are warmly welcome to visit our factory.

After-sale Service

2. The training video, detailed manual, and catalog sent with the machine. The customer could study the operation of the machine by watching the clear training video.

3. If there is a technical problem or new inquiry, Hymson has a fast response to service support by online or email even if need by the phone call.

4. Professional technical support and after sales following up. A free software update.

FAQ

Hymson laser produce fiber laser cutting machine in China, our primary products include steel plate cutter machine, metal plate cutting machine, tube laser cutting machine, precision laser cutting machine, laser welding machine.

2) Where is your fiber laser equipment applied to?

Our steel plate cutter machines come with the best steel plate laser cutting machine price, which is suitable for all kind of stainless steel, carbon steel, aluminium, copper, galvanized steel, electrolytic steel and silicon steel etc.

3) What are the advantages of your laser equipment?

By using Hymson laser, you can monitor end-to-end process and take complete control of all the machining process. The whole machining process will be done smoothly, which will greatly improve production efficiency. In addition, the precision and consistency of the products in mass production is guaranteed.

4) How to do control the quality when you produce laser equipment?

We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser cutting machine. In addition, all raw materials are strictly inspected in accordance with international standards before they are put into production.

5) Which countries are your laser machinery sold to?

Our laser cutting machine sell all over the world, such as United States, Spain,Netherlands,Poland,France,Turkey, Switzerland,Iran,Egypt, India, South Africa, Malaysia, Canada,Mexico,Colombia,Brazil,Chile,Korea, Japan and many other countries.

| Equipment Model | HF3015TU |

| Effective Cutting Range | 3000mmX1500mm |

| Effective Z-axis Stroke | 130mm |

| X/Y-axis Positioning Accuracy | ±0.03mm/m |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Maximum Speed of X/Y-axis Linkage Positioning | 140m/min |

| Maximum X/Y-axis Acceleration | 1.0g |

| Maximum Z-axis Positioning Speed | 30m/min |

| Maximum Z-axis Acceleration | 1.0g |

| Main Power Protection Grade | IP54 |

| Total Weight of Equipment | About 8T |

| Maximum Load of Workbench | 0.8T |

| Floor Space of Whole Machine | 8330mmX5700mm |