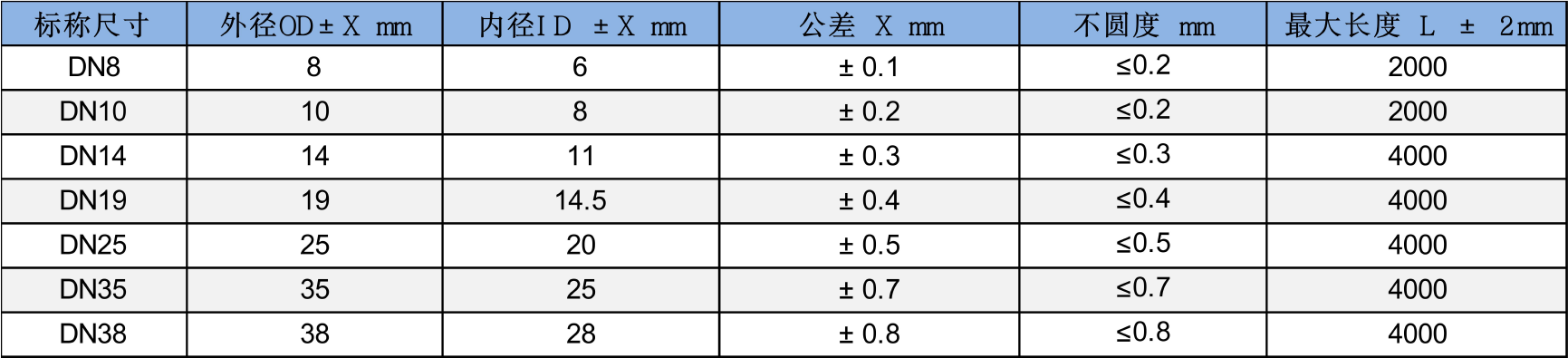

Standard specification for silicon carbide heat exchanger tubes

Typical applications

-

Used in tube heat exchanger (also known as shell and tube heat exchanger) equipment.

-

Suitable for various chemical substances cooling, condensation, heating, evaporation, film evaporation and absorption of chemical processes.

-

Especially suitable for all kinds of highly corrosive chemical substances as follows:

-

Bromide, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid and other strong corrosive acids;

-

Sodium hydroxide or other strong base;

-

Halogenated compound;

-

Salt solutions, and organic compounds.

-

Used in tube heat exchanger (also known as shell and tube heat exchanger) equipment.

Features and advantages

Silicon carbide heat exchanger tube

-

Silicon carbide heat exchange tube straightness standard: straightness (unit: mm/m)≦1.2%.Each heat exchange tube product must be fully through the standard pipe inspection before leaving the factory.

-

Silicon Carbide Heat Exchange Tubes Test Standard for Water Pressure Resistance: Each SiC tube is tested at 100Bar (60S) to ensure reliability and safety.

-

EN10204-3.1 Certificate available

-

Silicon carbide heat exchanger as the core of the new type of tubular heat exchanger, because of the silicon carbide has corrosion resistance, high temperature resistance, high thermal conductivity, high hardness, wear resistance and other excellent characteristics, silicon carbide heat exchanger is especially suitable for high temperature, high pressure, strong acid strong alkali corrosion, high-speed airflow erosion, particle wear and other working environment;It is an excellent high performance product to replace graphite heat exchanger, stainless steel heat exchanger, tantalum metal heat exchanger, Hastelloy heat exchanger, fluorine plastic heat exchanger and glass lining heat exchanger.

-

SiC heat exchanger has excellent heat exchange efficiency, more compact than the traditional heat exchange equipment, small volume, compared with glass lining heat exchanger to save 70% of the installation space (the same heat transfer required smaller heat exchange area).Because it is easy to disassemble, the silicon carbide heat exchanger tube can be entered directly into the side of the tube for cleaning or inspection, resulting in low maintenance costs.