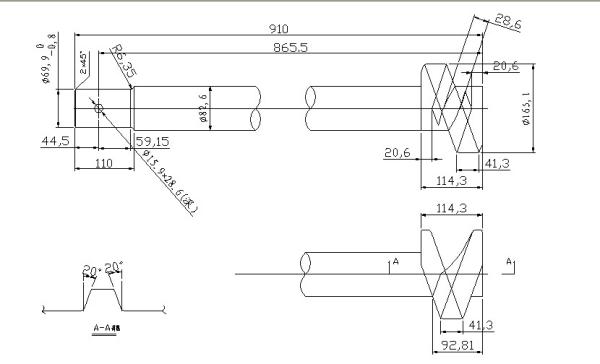

Zirconia stirrers and tappets for glass production

Zirconia is used to manufacture the components for glass production. Stirrers are used for homogenization and tappets (plungers) are used for portioning glass melts. They must be able to withstand extremely high temperatures and corrosive glass melts. Our products are ideally suited to these challenging conditions.

Your advantages at a glance:

-

-

Good dimensional stability

-

Excellent corrosion resistance

-

Good electrical and thermal conductivity

-

Advantages of ZrO2 stirrers compared with other ceramic stirrers:

- Better stirring action thanks to unlimited design possibilities

- Small shaft diameter and large blade diameter for more effective stirring

- Higher mechanical stability

- Better thermal shock resistance

- No contamination of the glass melt

- Considerably longer service life

We have stock for alumina (Al2O3) and make under request, in the following materials:

- magnesia partially stabilized zirconia (Mg-PSZ),

- yttria-stabilized tetragonal zirconia (Y-TZP) zirconia

- partially stabilized with yttria (Y-PSZ),

- zirconia fully stabilized with yttria (Y-FSZ),

- zircon (ZrSiO2),

- aluminum titanate (Al2TiO5),

- mullite (Al6Si2O13)

We provide the following to suit your application:

- Metallurgy flow control: Tundish ZrO2 metering nozzle inset and converter slag-stopping ZrO2 slide plate, ZrO2 Ring, Insert, Etc.

- Amorphous Alloys, metal Al, Cu, amorphous alloys powder air atomizing nozzle.

- Aritificail crystal(Sapphire) Growing Equipment- Rare compsite SS ceramic thermal field.

- Ti-Alloy industry-Sintering gasket(tray), smelting crubible.

- Sintering industry-Preheating ZrO2 parision, metal sputtering, target, tile, etc.

- Glass Industry- (95 HP ZrO2) photovoltaic glass, shale glass, etc., cover plate & lip brick, etc.