Automatic Sealing and High-Efficient Launch Insulating Glass Vertical Type Desiccant Filling Machine

Product Description

Automatic Sealing and High-Efficient Launch Insulating Glass Vertical Type Desiccant Filling Machine

This type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. This equipment use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. It is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The dispensing cylinder uses vertical rotary support system and it makes the refill of butyl easier. It can prolong the life of squeezing system and set the heating time in 24 hours with electricity and air pressure. The distance of squeezing head can be adjusted automatically according to different aluminum spacer. The machine has reached the worldwide technology with the characteristic of complete function and stable working mode.

Main Technical Parameter

| Item. | Spec. | |||

| filling aluminum frame max size | 2000mm*2000mm | |||

| filling aluminum frame min size | 300mm*250mm | |||

| molecular sieve diameter needed | 0.5-0.9mm | |||

| Dimension | 1300mm*1100mm*3650mm | |||

| Air source | ≥0.65MPa | |||

| Total power | 220V 50Hz 1.5Kw | |||

| Name | Brand | |||

| PLC | Germany SIEMENS | |||

| Triplet | TAIWAN AIRTAC | |||

| Low voltage electrical apparatus | Germany SIEMENS | |||

| Solenoid valve | TAIWAN AIRTAC | |||

| Sensor | Korea AUTONICS | |||

| Gas driller | Taiwan BOA | |||

| Guide | Taiwan TBI | |||

| Switch power | Taiwan TEND | |||

Advantages & Features

Benefits & Advantages

1.The machine height of can be adjusted according to the size of spacer frame 2.The machine time could be adjusted 3.The machine adopts auto loading and replenish 4.The machine adopts auto drilling, filling and sealing function 5.It use Germany Siemens PLC control system 6.The touching screen interface, simple and visible 8.It adopts vacuum pump loading device ,increase the loading speed 9.The desiccant filling machine could use big bucket desiccant ,save desiccant refill time, improve the work efficiency.

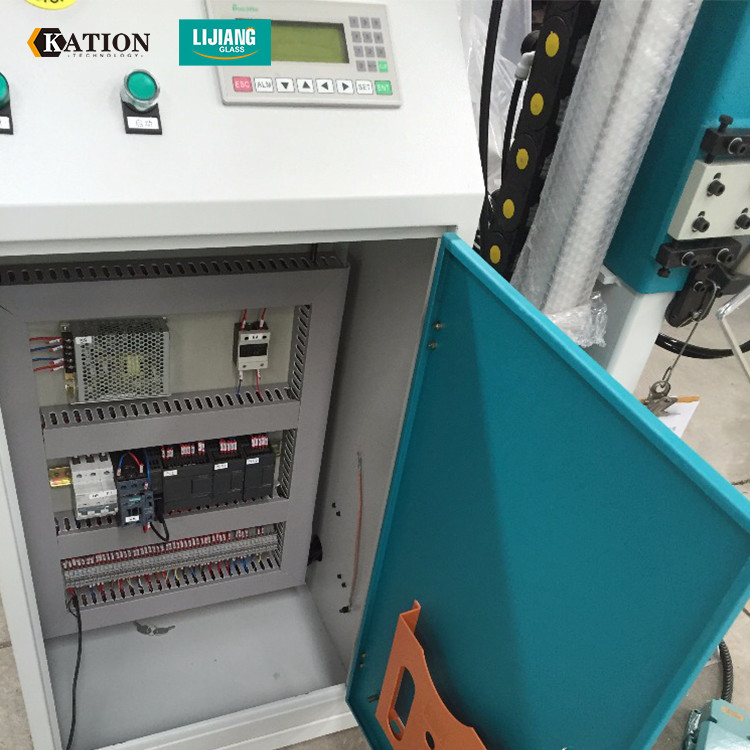

The Unique ID Code Number

All the electrical wires of the machine parts, have the unique ID code number, it could match with specification, also it will be make it easy for the communication with customers in the after sales service on furture.

The Touching Screen Interface

The touching screen interface, which the parts of machine, is simple and visible; and also, the filling time could be adjusted according to the size of spacer frame in the touch screen.

The Materials Bucket

The desiccant filling automatically loading from the materials bucket. (When the material was used up the sensor will alarming, desiccant will automatically loading.)

The Electrical Component

The electrical component are all Germany Brand-Siemens, which is adopt internationally renowned brands to ensure the stability of the equipment.