The placement of components

Once the netlist is exported, it is imported into the routing software which translates each line of code into connections and with all the indications of the components present.

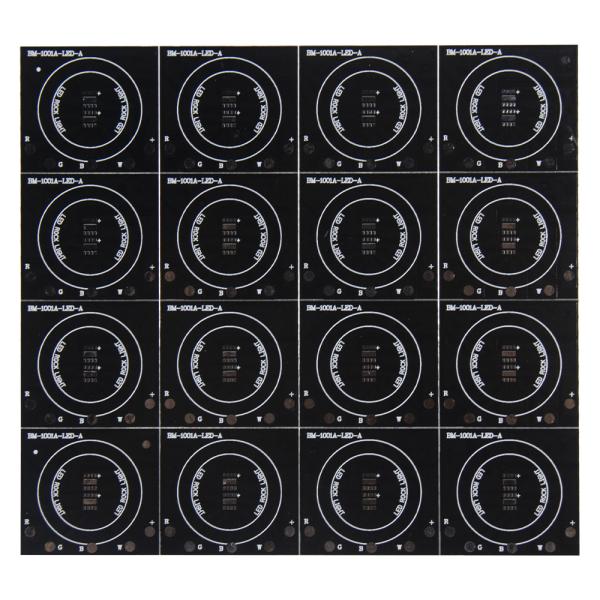

Positioning is one of the most critical phases of the Master PCB because the choice and positioning criteria adopted for the components will influence the routing of the tracks.

A good positioning at this stage will avoid many problems of interference, crosstalk, and coupling of critical signals.

The positioning of the components will always be carried out taking into account the electrical functions of the components, avoiding the no-go areas for placement and for the routing of the tracks.

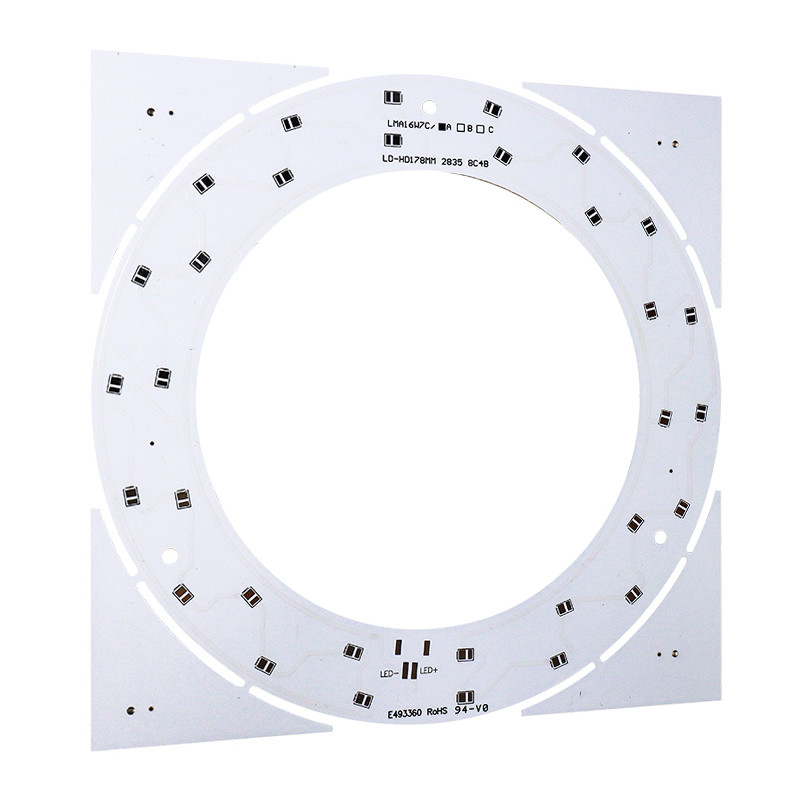

Track routing is the interconnection of all the connections present in the wiring diagram between the components.

The tracks that will be created will connect the pin pads of the components and will use multiple interconnection layers to concentrate all the connections inside the PCB.

Each layer is interconnected by metalized holes, also called vias.

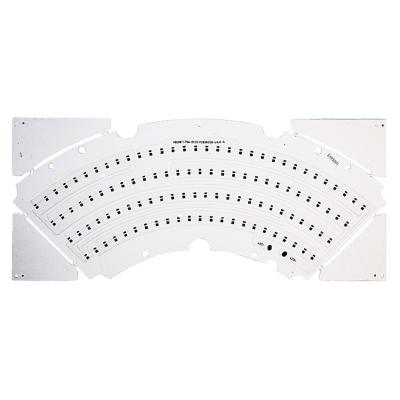

The size of the tracks will be suitably calibrated according to the electrical constraints of the signals that will cross the board.

All electrical insulation (track-track, track-pitch, pitch-pitch, track-floor, floor-via, track-away, pitch-away, etc.) must be carefully chosen.