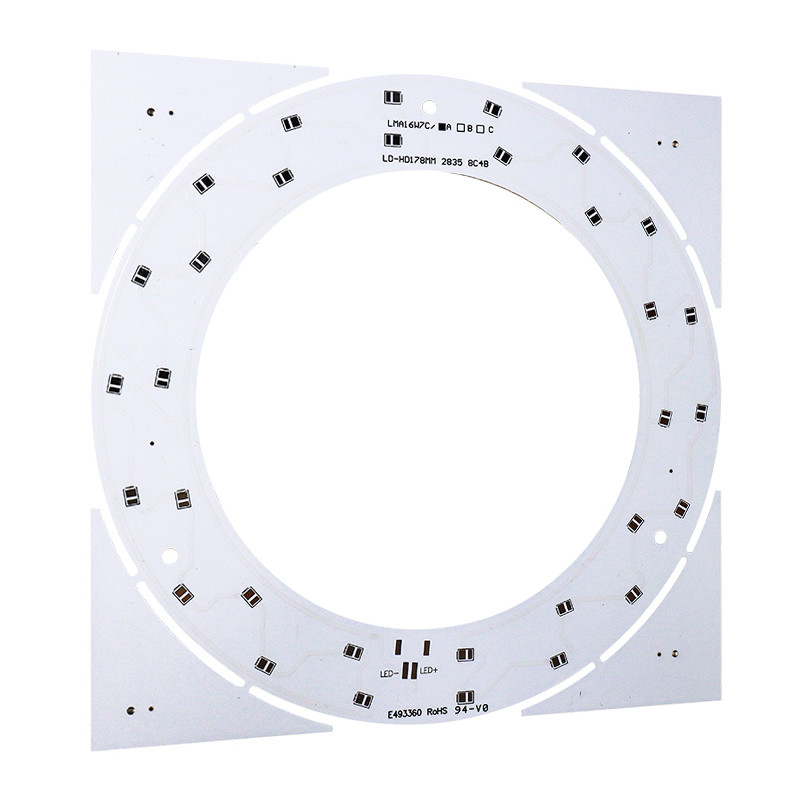

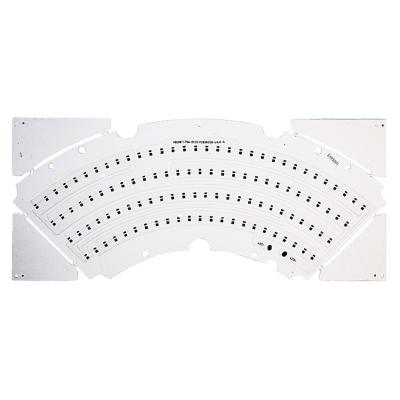

LED Circuit Board Materials

An LED PCB is a metal core PCB, which uses metal as the base material, such as Aluminum, Iron, or Copper. In most cases, LED PCBs are Aluminum PCBs. Aluminum is mostly used for the fabrication of LED PCBs because it is cheap and lightweight as compared to other metals. Thus, we can say, an LED PCB is similar to an Aluminum PCB.

Aluminum LED PCB comprises three layers. These layers are the copper layer, dielectric layer, and aluminum base layer. The topmost layer is the copper layer, which makes the electrical connections in the PCB. This layer is standard in all types of PCBs. For the protection of this layer, a surface finish is used. Copper provides excellent conductivity and completes the circuit.

The next layer is the dielectric layer, which is very important in metal core PCBs. This dielectric layer serves as an insulator, and it prevents the flow of current in the base aluminum layer. The layer has excellent thermal conductivity, which is good for heat dissipation.

The last layer of the PCB is the base layer, which is made of Aluminum. This layer makes the board unique and provides it a separate identity. Due to the base layer, the PCB is more durable than FR-4. It can withstand wear and tear and high temperatures. Moreover, it is excellent for heat dissipation. It’s lighter than copper and iron.