Some Considerations for Designing an LED PCB

Designing an LED PCB is a process that requires some standards and rules to be followed. It might sound like you only need to pop some LEDs on the printed circuit board, and you are good to go, but that’s not the case. Here is what it takes to design an LED PCB:

-

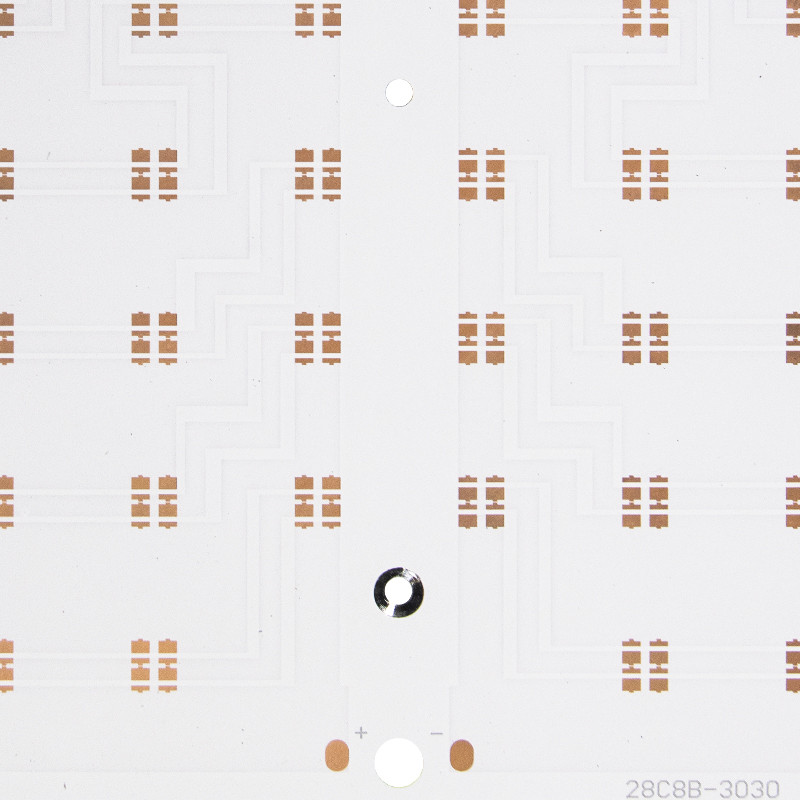

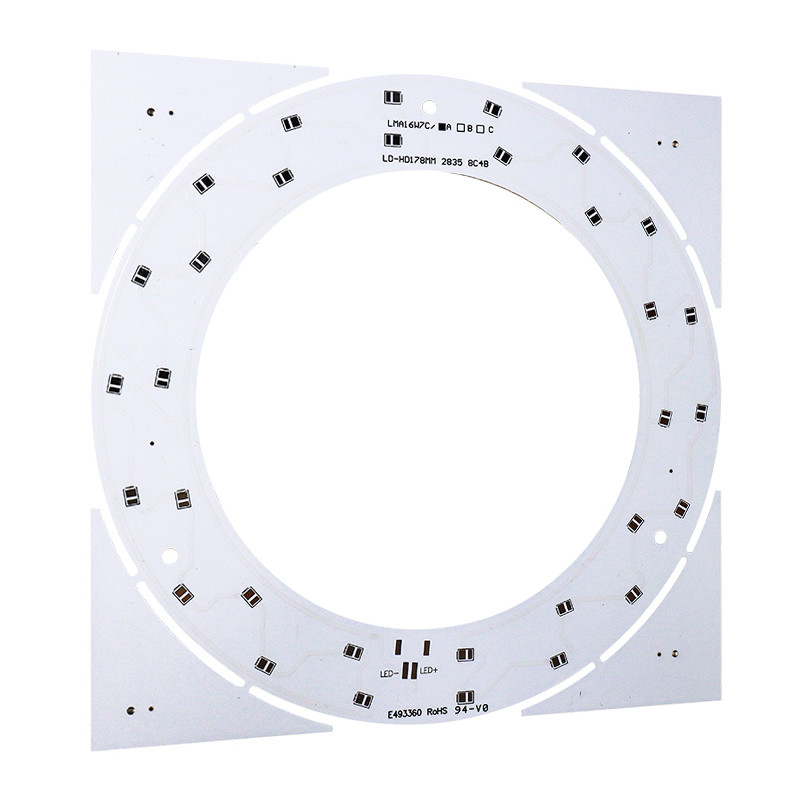

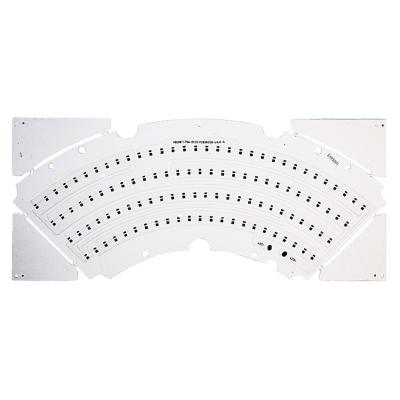

Component Placement: the right component placement is what it takes to design an efficient LED circuit board. Placing the right component at the right spot is crucial in PCB designing. Along with LEDs, an LED PCB contains other components such as connectors, resistors, and thermistors, which need to be placed at a suitable distance from each other. The creepage (the shortest distance between two components) and the clearance (distance measured through the air) should be considered when designing an LED PCB to avoid damaging consequences such as overvoltage.

-

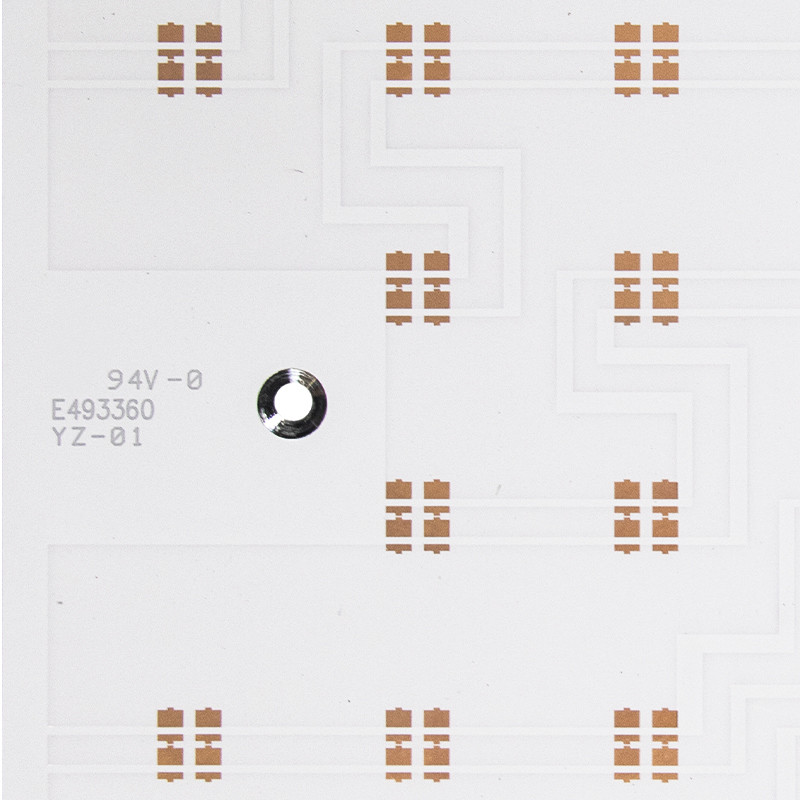

PCB Material: choosing the right material for your LED PCB is challenging because there are multiple materials available in the market, and each has its own pros and cons. You’ll need to study their merits and demerits to find out which material is suitable for your application. You might need professional help for it, and the best place to go to is PCBONLINE. We provide free and professional suggestions.

-

Thermal Management: LEDs and other components placed on the PCB will certainly dissipate heat energy, and if that energy is not channeled the right way, then it might end up damaging your circuit board. The addition of vias and heat sinks will allow you to manage the heat energy present within the board. Professionals at PCBONLINE knows exactly what it takes to manage the heat produced by electronic components.

-

Tracking: tracking is the process of ensuring that no part of the net is left open or is forming a short circuit. After the components are placed, the process of tracking begins. The flow of current is also monitored such that it does not contribute to the production of heat energy in the circuit.

A great example of machine vision systems using LED is a barcode scanner. Typically, a red LED is used in barcode scanners in supermarkets and grocery stores. LEDs are a source of bright light and are compact in size, making them a great fit for machine vision systems.