PCB CORES

Engineers design printed circuit boards to work best within their particular application. The designs can specify the nature of the circuit, the PCB coating material, the size of the PCB and a variety of other qualities. One of the most basic qualities to change, however, is the core of the circuit board.

PCB bases come in a variety of materials, including:

-

FR-4: Most common of these materials is FR-4, a base composed of glass and epoxy. While fire-retardant, FR-4 tends to be relatively inefficient at transferring heat.

-

Epoxies: Another, albeit less common substrate for PCBs is a material known as an epoxy. While less durable than other options, epoxy-based PCBs are much cheaper to manufacture.

-

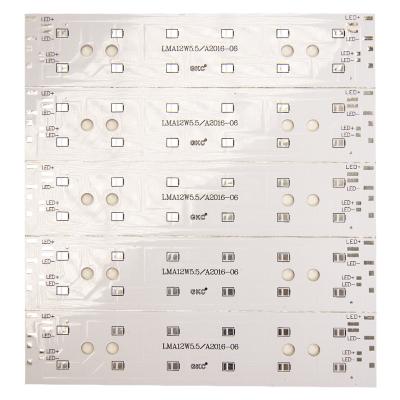

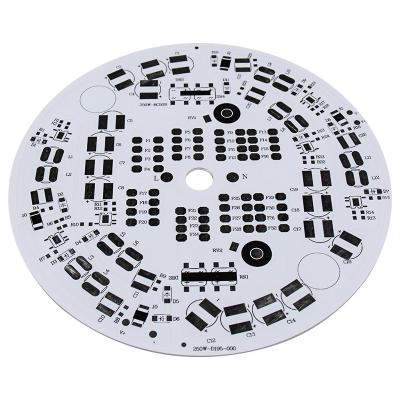

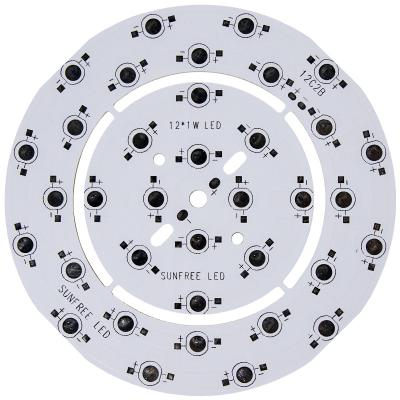

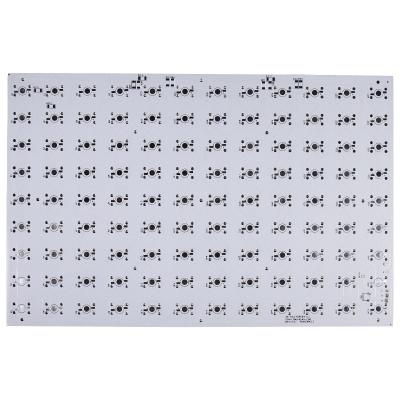

Metal-core: Metal-core PCBs are very effective for a variety of applications, specifically those involving heat transfers. These bases consist of metal, usually aluminum, laminated with copper. These metals give the circuit board improved electrical insulation and thermal conductivity.

When thermal qualities are not as important, FR-4 or epoxy bases are more common, as these tend to be relatively less expensive. However, when thermal qualities are important for the proper function of the end product, metal-core printed circuit boards are likely the solution.