Screw Elements For Parallel Twin Screw Extruder Screw elements Used In The Plastic And Polymer Industries

1. Product Introduction:

We manufacture screw and kneading segments for co-rotating twin screw extruders ranging from 20 mm to 200 mm and over. Our manufacturing specializes in segmented screws for twin screw extruders and is optimized for flexible order handling.

2. Types of Screw Elements

* Convey Screw Segment

* Mixing Screw Segment

* Kneading Block & Disk

* Transition Screw Element

* Deep groove transfer element

* Screw element for side feeder

* 1-flighted,2-flighted,3-flighted screw elements

3. Main Materials For Screw Elements

For wear application:

* Tool Steel : W6Mo5Cr4V2;

* PM-HIP material : SAM10,SAM26,SAM39,CPM10V,CPM9V

For corrision application:

* Nitrided Steel: 38CrMoAI;

* PM-HIP material : SAM26,SAM39,CPM10V,CPM9V

For wear and corrision application:

* PM-HIP material:SAM26,SAM39,CPM10V,CPM9V

Other materials:

After several years researching, we developed the new materials of OS02H, Which can achieve the hardness of 57-62HRC, we also have OS02M , which can have the hardness of HRC40-45, but have the same corrosion resistance of HC276 materials, while the HC276 materials only has hardness of HRC22-26.

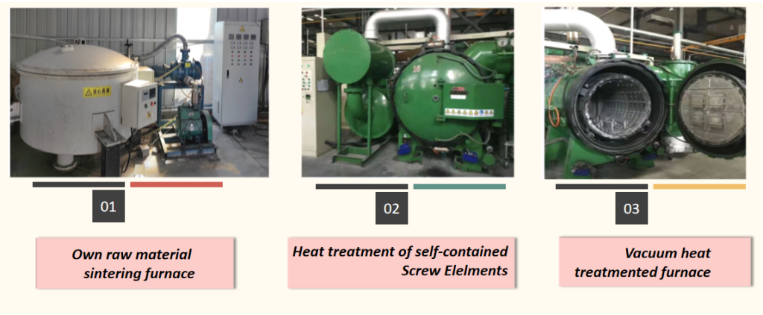

4.Production Equipments

At present, the company’s factory area exceeds 3000 square meters, and an additional 3000 square meters are under planning and design, covering the complete production process of material research and development, main component production, and testing. The company has 6 technical person,over 40 workers, and multiple imported production and testing equipment from Taiwan and Germany.

5. Why Choose Us

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products, while the main supplier in the market only buy raw materials for machining.

2) Continuously Research and improving the materials based on different application and different customer requirements. For example, for the screw elements used in hydrofluoric acid , we get our new materials of OS02M, its corrosion resistance is similar to HC276, but its hardness can reach to HRC40-45. so this materials both has good corrosion resistance and high wear resistance. It is the first choice Materials of screw elements used in strong corrossion industry.