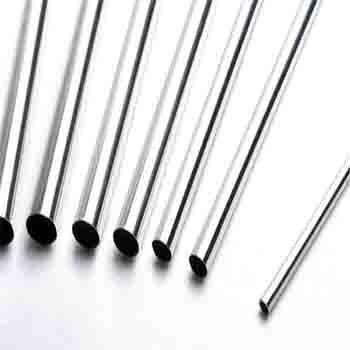

industry, mechanical instrument and so on. In In addition, in the same bending and torsional strength, stainless steel pipe has light weight, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also often used for furniture, kitchenware, etc.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)