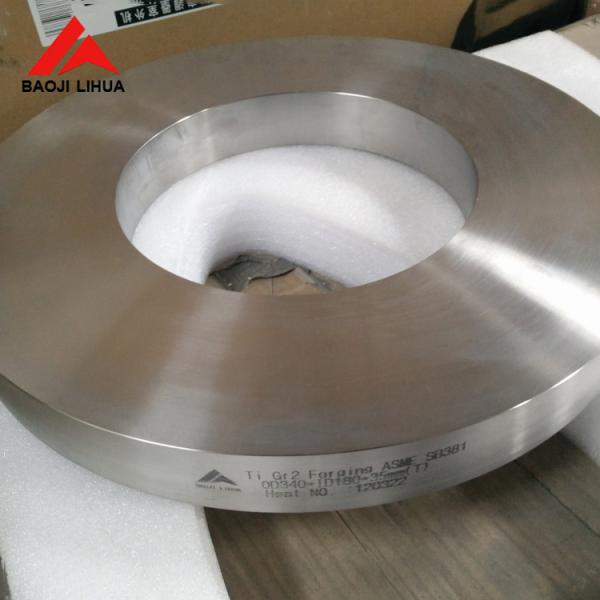

Surface treatment: polishing, chamfering.

application area:Aerospace, aviation, military industry,

light industry, chemical industry, textile, medical,

petrochemical and other fields.

Gr7 Titanium Forged Ring Titanium Forgings

Surface treatment: polishing, chamfering.

application area:Aerospace, aviation, military industry,

light industry, chemical industry, textile, medical,

petrochemical and other fields.

Gr7 Titanium Forged Ring Production process

Forging, die forging, rotary forging, precision forging and welding

Testing

Tensile strength test, hardness test, chemical composition test, ultrasonic test, radiographic test, penetration coloring test.

Surface

Surface treatment: polishing, chamfering.

Surface quality: the surface roughness Ra value of the two end faces shall not be greater than 3.2l μ m (subject to the requirements of ultrasonic inspection), the surface roughness Ra value of the inner and outer sides shall not be greater than 12.5 μ m (Ra value shall not be greater than 3.2 μ m when ultrasonic testing is required for the outer circumferential surface), and the chamfer radius shall be 5-15mm.

Application area

Aerospace, aviation, military industry, light industry, chemical industry, textile, medical, petrochemical and other fields.

| Chemical requirements | |||||||||||

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

6. Related Products