Introduction to Titanium Pipes in Heat Exchangers

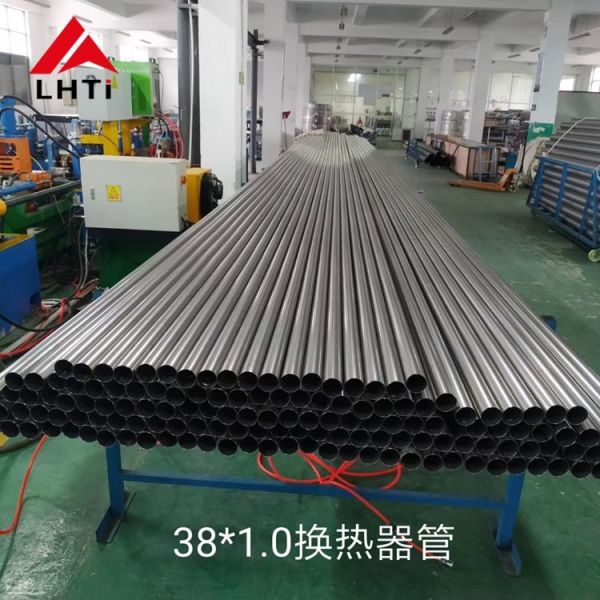

Heat exchangers play a crucial role in various industrial processes by transferring heat between two or more fluids without mixing them. Among the materials used for constructing these systems, titanium has gained significant attention due to its exceptional properties. The 19mm titanium pipe offers a unique balance of strength, lightweight characteristics, and corrosion resistance, making it an ideal choice for heat exchanger applications. This article explores the advantages, manufacturing processes, and various uses of 19mm titanium pipes in heat exchangers.

Advantages of 19mm Titanium Pipes

One of the primary advantages of using 19mm titanium pipes in heat exchangers is their remarkable corrosion resistance. Unlike traditional materials such as stainless steel or copper, titanium is highly resistant to pitting and crevice corrosion, especially in aggressive environments like those found in chemical processing or seawater applications. This property ensures a longer lifespan for the heat exchanger, reducing maintenance costs and downtime, which are critical factors in industrial settings.

Another significant benefit of titanium pipes is their lightweight nature. Weighing approximately 40% less than stainless steel, 19mm titanium pipes facilitate easier installation and transport. This reduction in weight is particularly beneficial in industries where structural support is a concern, allowing engineers to design lighter supporting frameworks. Additionally, the lower weight contributes to overall energy savings during transport and installation, further enhancing the cost-effectiveness of using titanium in heat exchangers.

Thermal conductivity is another important factor in the performance of heat exchangers. While titanium is not the best conductor compared to materials like copper, its thermal conductivity is still sufficient for many applications. Moreover, the combination of the 19mm diameter and the spiral design often employed in titanium pipes allows for improved heat transfer efficiency. This enhanced performance can lead to reduced energy consumption and increased operational efficiency, making titanium pipes a smart choice for modern heat exchanger designs.

| Item | Standard | Material | Size(mm) |

| Heat exchanger And Condenser tube | ASTMB338,ASTMB337, ASTMB861 | Grade1,2,3 | OD(5-114)X(0.3—10)XL1200mmMax |

| Corrosion Resistant Tubes | ASTMB338 | Grade7,Grade12 | OD(5-114)X(0.5—4.5)Xlength 12000mmMax |

| BikeFrame/Wheelchair/Exhaust tube/Pipes | ASTMB338 | Gr9/Ti3Al2v5 | OD(38.1—44.5)X(0.9-3.15)X(L1000—2000MM) |

| Automobile&MotorCycle Exhaust Tube/Pipes | ASTMB337/338 | Gr1,Gr2,Gr9 | OD(38.1—88.9)X1.2X(L1000—2000mm) |

| Marine Industry | ASTM/AMS | Gr2,Gr5,Gr7,Gr12 | OD(23.1-210)X(W0.5-6.0)X(L1000-6000mm) |

Key Properties of Grade 2 Grade 5 Titanium Pipe

Grade 2 and Grade 5 titanium are two of the most commonly used titanium alloys, each with distinct properties suited for different applications. Here's a breakdown of their key properties:

Grade 2 Titanium (Commercially Pure Titanium)

Grade 2 titanium is often referred to as CP Ti Grade 2 or commercially pure titanium. It is one of the most widely used grades of titanium because it offers excellent corrosion resistance, good strength, and weldability.

1. Chemical Composition

- Titanium (Ti): ~99%

- Small amounts of oxygen, carbon, nitrogen, hydrogen, and iron.

- Grade 2 titanium is essentially pure titanium with low levels of alloying elements, making it ideal for corrosion-resistant applications.

2. Mechanical Properties

- Tensile Strength: Approximately 345–450 MPa (50–65 ksi)

- Yield Strength: Around 275 MPa (40 ksi)

- Elongation: 20–30%

- This gives it good ductility, making it easily formable and suitable for various applications where flexibility is important.

- Modulus of Elasticity: ~105 GPa (15.2 million psi)

3. Corrosion Resistance

- Excellent resistance to a wide range of corrosive environments, including seawater, chlorides, acids, and oxidizing agents.

- Resistant to pitting, crevice corrosion, and stress-corrosion cracking.

- Often used in chemical processing and marine applications where exposure to corrosive substances is common.

4. Weldability

- Excellent weldability with processes like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding.

- Can be welded in both as-received and annealed conditions without compromising mechanical properties.

5. Heat Resistance

- Can handle moderate temperatures up to around 400°C (752°F).

- Not as heat-resistant as some other titanium alloys like Grade 5.

6. Density

- Density: ~4.51 g/cm³ (4510 kg/m³)

- Slightly denser than some of the more alloyed titanium grades, but still relatively lightweight compared to steel.

Grade 5 Titanium (Ti-6Al-4V)

Grade 5 titanium, also known as Ti-6Al-4V, is an alpha-beta alloy containing 6% aluminum and 4% vanadium. It is one of the most popular titanium alloys due to its high strength, light weight, and excellent fatigue and corrosion resistance.

1. Chemical Composition

- Titanium (Ti): Balance (approximately 90%)

- Aluminum (Al): 6%

- Vanadium (V): 4%

- Iron (Fe), Oxygen (O), and Carbon (C) are present in trace amounts.

2. Mechanical Properties

- Tensile Strength: Approximately 895–1,200 MPa (130–175 ksi)

- Much higher than Grade 2 titanium, making it suitable for high-stress applications.

- Yield Strength: Around 828 MPa (120 ksi)

- Higher yield strength than Grade 2, making it more suitable for structural applications requiring better strength-to-weight ratios.

- Elongation: 10–15%

- Modulus of Elasticity: ~110 GPa (16 million psi)

3. Corrosion Resistance

- Good corrosion resistance to a wide range of environments, including seawater, chlorides, sulfuric acid, and acids.

- Comparable to Grade 2 in terms of resistance to corrosion in most environments but slightly less resistant in some aggressive, chloride-rich environments due to the presence of alloying elements like aluminum and vanadium.

4. Weldability

- Good weldability but requires more care compared to Grade 2 due to its higher strength and alloy content.

- Common welding processes include TIG, MIG, and EB (electron beam) welding.

- Proper heat treatment and welding procedures are critical to maintain the strength and mechanical properties.

5. Heat Resistance

- Can perform at higher temperatures than Grade 2, with a maximum continuous operating temperature around 400–600°C (752–1,112°F).

- Exhibits good thermal stability and can withstand moderate thermal cycling.

6. Density

- Density: ~4.43 g/cm³ (4430 kg/m³)

- Lighter than most steel alloys, contributing to its widespread use in aerospace and automotive applications where weight reduction is important.

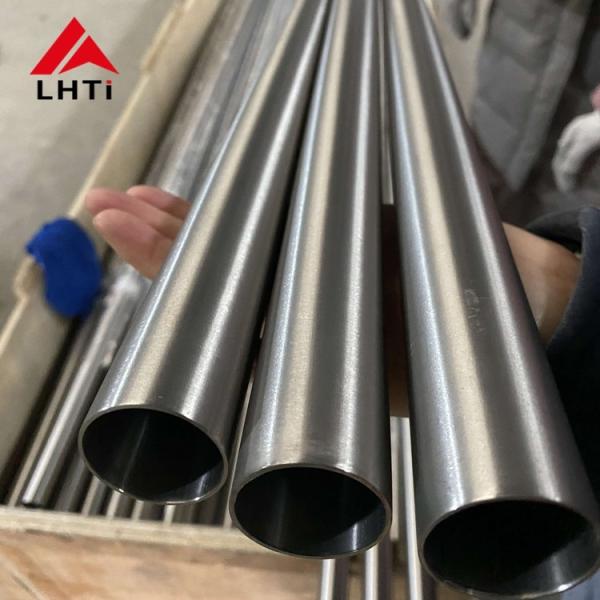

Manufacturing Processes of 19mm Titanium Pipes

The manufacturing of 19mm titanium pipes involves several advanced techniques that ensure high quality and performance. Initially, high-purity titanium is sourced, often in the form of ingots that undergo processes like vacuum arc remelting to achieve the desired material properties. This initial step is vital for producing pipes that meet stringent industry standards, particularly in sectors like aerospace and chemical processing.

Once the raw material is prepared, the titanium undergoes processes such as extrusion or rolling to create the tubular shape. The specific diameter of 19mm is achieved through precise machining techniques that maintain the structural integrity of the material. Post-manufacturing processes may include heat treatment to enhance mechanical properties and relieve internal stresses, which is essential for ensuring durability under operational conditions.

Welding plays a critical role in assembling titanium pipes for heat exchangers. Gas tungsten arc welding (GTAW) is commonly used due to its capability to produce strong and defect-free joints. This method is particularly important for maintaining the corrosion resistance of the titanium, as poor welding can create weak points susceptible to environmental damage. Rigorous quality control measures, including non-destructive testing and dimensional inspections, are implemented to ensure that the final product adheres to all specifications.

ASTM B338 is a standard specification that covers seamless and welded titanium tubes and pipes for various applications, particularly in the aerospace, chemical processing, and marine industries. Here’s a concise introduction to ASTM B338 titanium tubes:

Overview of ASTM B338

-

Scope:

- ASTM B338 specifies requirements for titanium tubes in various grades, including commercially pure titanium and titanium alloys. The tubes can be either seamless or welded, and they are designed for use in high-performance environments.

-

Material Grades:

- Common grades include CP (Commercially Pure) titanium grades (Grade 1 to Grade 4) and alloyed grades (e.g., Grade 5, Ti-6Al-4V). Each grade offers different properties, such as strength, ductility, and corrosion resistance.

-

Applications:

- The specification is primarily used in industries that require high strength-to-weight ratios and excellent corrosion resistance, such as aerospace, chemical processing, marine engineering, and medical applications.

-

Manufacturing Processes:

- The tubes are produced through processes like hot working, cold working, and heat treatment to meet specific mechanical properties and dimensions. They may also undergo inspections for quality assurance.

-

Standards and Testing:

- ASTM B338 outlines requirements for testing mechanical properties, corrosion resistance, and dimensions, ensuring that the tubes meet industry standards for performance and safety.

-

Specifications:

- The standard provides detailed requirements for tube dimensions, wall thicknesses, tolerances, and surface finishes, ensuring that they meet the rigorous demands of their intended applications.

Benefits of ASTM B338 Titanium Tubes

- Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, including seawater and acidic conditions.

- Lightweight: Lower density compared to steel, making them suitable for applications where weight savings are critical.

- Strength: High tensile strength and fatigue resistance, ideal for demanding applications.

- Biocompatibility: Suitable for medical applications, as they do not react adversely with bodily tissues.

Key Properties of ASTM B338 Titanium Tubes:

The ASTM B338 specification highlights several critical properties of titanium tubes, which contribute to their performance across various applications. Here are the key properties:

1. Mechanical Properties

- Tensile Strength: ASTM B338 titanium tubes exhibit high tensile strength, enabling them to withstand significant stress without deforming. For example, commercially pure titanium (Grades 1 and 2) typically has a tensile strength ranging from 240 to 450 MPa, while titanium alloys like Ti-6Al-4V can exceed 900 MPa.

- Yield Strength: Yield strength indicates the maximum stress that can be applied before permanent deformation occurs. Commercially pure titanium has yield strengths around 170 to 350 MPa, whereas titanium alloys like Ti-6Al-4V have much higher yield strengths, enhancing their suitability for load-bearing applications.

- Elongation: This property reflects the ductility of the material, indicating how much it can stretch before breaking. ASTM B338 tubes generally demonstrate good elongation (around 20% or higher), which is crucial for applications requiring forming and shaping.

2. Corrosion Resistance

- Exceptional Resistance: Commercially pure titanium is highly resistant to corrosion, particularly in aggressive environments such as seawater, acidic conditions, and oxidizing media. This makes it ideal for marine and chemical processing applications.

3. Lightweight Nature

- Density: Titanium is about 45% lighter than steel, which significantly benefits applications where weight reduction is essential. This lightweight characteristic allows for the design of more efficient structures without sacrificing strength, particularly in aerospace and high-performance automotive applications.

4. Fatigue Resistance

- Durability Over Time: Titanium alloys exhibit excellent fatigue resistance, making them suitable for cyclic loading applications, such as in aerospace components where repeated stress occurs over time.

5. Thermal Properties

- High-Temperature Performance: Titanium can maintain its strength and integrity at elevated temperatures, making it suitable for applications like exhaust systems in automotive and aerospace sectors.

6. Biocompatibility

- Medical Applications: The biocompatible nature of commercially pure titanium makes it an excellent choice for medical implants and devices, minimizing the risk of adverse reactions in the human body.

Summary

The combination of high tensile and yield strength, excellent corrosion resistance, lightweight nature, and durability makes ASTM B338 titanium tubes highly versatile and suitable for a wide range of demanding applications, from aerospace to medical devices. These properties ensure efficient design and performance, particularly in environments where traditional materials may fail.

Applications of 19mm Titanium Pipes in Heat Exchangers

The versatility of 19mm titanium pipes makes them suitable for various applications in heat exchangers across multiple industries. In the chemical processing sector, these pipes are frequently used in systems that handle corrosive substances, where traditional materials would fail. Their ability to withstand harsh chemicals while maintaining structural integrity ensures reliable operation and minimizes the risk of equipment failure.

In the food and beverage industry, maintaining hygiene and preventing contamination is paramount. The non-reactive nature of titanium makes 19mm pipes an excellent choice for use in pasteurization and sterilization processes. By ensuring that no harmful substances leach into products, these pipes help companies comply with strict safety regulations, thereby protecting consumer health and maintaining product quality.

The pharmaceutical industry also benefits significantly from the application of 19mm titanium pipes. In processes requiring precise temperature control, such as vaccine production, these pipes offer consistent thermal performance without compromising the integrity of sensitive compounds. The biocompatibility and corrosion resistance of titanium make it a preferred choice for applications where maintaining purity and safety is critical.

Future Trends in Titanium Seamless Pipe Technology

As industries continue to evolve, the demand for titanium seamless pipes in heat exchangers is expected to grow. Ongoing research and development efforts are focused on enhancing the properties of titanium alloys, enabling them to perform even better under extreme conditions. Innovations in manufacturing techniques, such as additive manufacturing, are also opening new avenues for producing complex geometries and tailored designs that meet specific application requirements. These advancements will likely lead to increased adoption of titanium seamless pipes in various industries.

Sustainability is becoming a significant driver in material selection, and titanium's recyclability contributes to its appeal in modern applications. As industries strive to reduce their environmental footprint, the use of durable and recyclable materials like titanium will become increasingly important. Future developments may focus on improving recycling processes for titanium, ensuring that it remains a sustainable option for heat exchangers and other critical applications.

Digitalization and smart technologies are also set to revolutionize the way heat exchangers are designed and monitored. Integrating sensors and real-time monitoring systems into titanium seamless pipe designs could provide valuable insights into performance and condition over time. Such advancements would not only enhance operational efficiency but also enable predictive maintenance strategies, ultimately leading to reduced operational costs and improved reliability.