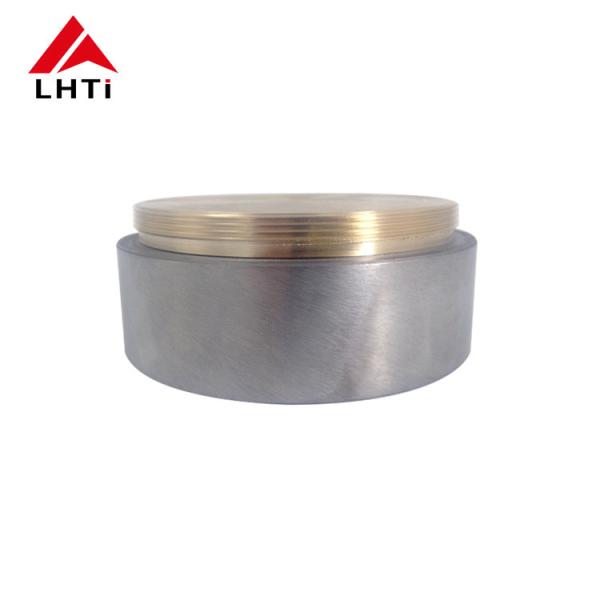

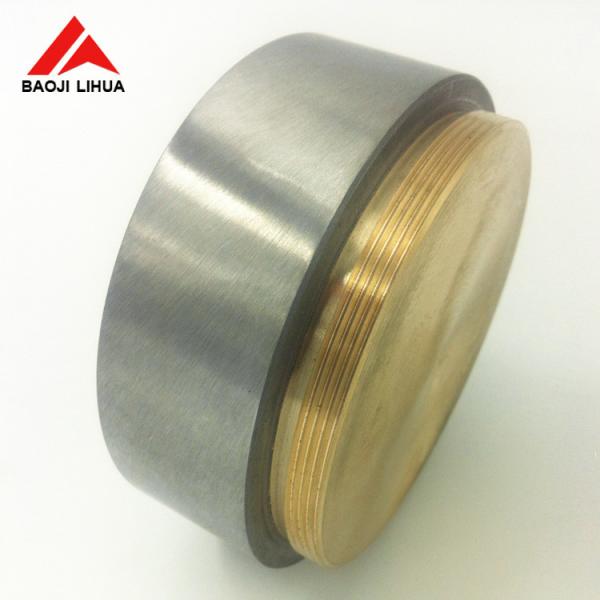

Titanium Target Silver Sputtering Target Titanium Disc to High Purity Sputtering in Medical Applications

In the realm of Physical Vapor Deposition (PVD) processes, titanium sputtering targets are critical in the production of thin films used in various medical applications. These thin films are crucial for enhancing the performance, durability, and biocompatibility of medical devices such as implants, stents, prosthetics, and surgical tools. Among the various titanium grades, Grade 5 (Ti-6Al-4V) and Grade 7 (Ti-0.15Pd) are particularly notable due to their unique properties that make them ideal for medical applications when used in sputtering.

| Technical Parameters | Description |

| Product Name | Titanium Disc |

| Material | Titanium Alloy |

| Shape | Round |

| Thickness | 35mm-550mm Or As Your Requirement |

| Diameter | 150mm-1300mm Or As Your Requirement |

| Color | Silver |

| Surface Treatment | Polished |

| Application | Industrial |

| Package | Plywood Case Or According to Your Requirement |

Titanium-aluminum alloy targets are specialized materials used in sputtering processes to deposit thin films with specific properties. These targets are made from a combination of titanium (Ti) and aluminum (Al), and they offer unique characteristics that make them valuable in various industrial applications.

Characteristics of Titanium Aluminum Alloy Targets:

-

High Purity:

- Titanium-aluminum alloy targets are produced with high purity, typically 99.5% or higher. This high purity ensures that the thin films deposited during sputtering are free from impurities, providing excellent performance and uniformity in applications that require precise coatings.

-

Fine Particle Size:

- The alloy targets are manufactured with a fine particle size, which enhances the efficiency of the sputtering process. Smaller particle sizes enable a more uniform deposition of the film on the substrate, improving the quality of the coating.

-

Easy Sintering:

- Titanium-aluminum alloys exhibit good sintering properties, which means they can be easily processed into dense and solid forms. This is crucial for ensuring that the target is durable, reliable, and capable of withstanding the stresses of the sputtering process without degradation.

-

Good Formability:

- Titanium-aluminum alloy targets are known for their excellent formability. This characteristic allows them to be manufactured into various shapes and sizes, ensuring compatibility with different sputtering systems and enhancing their versatility in a wide range of applications.

Applications of Titanium Aluminum Alloy Targets:

Titanium-aluminum alloy sputter targets are used in various industries due to their distinct properties, such as wear resistance, corrosion resistance, and the ability to form strong coatings. Some key applications include:

-

Cutting Tools:

- Titanium-aluminum alloy coatings are commonly used in cutting tools, where they improve wear resistance, corrosion resistance, and thermal stability. These coatings extend the lifespan of tools like drills, end mills, and lathe tools, making them more efficient in high-speed machining.

-

Cemented Carbide Drill Bits and Tools:

- Cemented carbide drill bits and tools benefit from the titanium-aluminum alloy coating as it significantly enhances the tool's performance in abrasive and high-temperature conditions. The coating also improves the tools' cutting ability and resilience when drilling or machining tough materials.

-

Cemented Carbide Ceramic Tools:

- These coatings are applied to ceramic tools made from cemented carbide, enhancing their abrasion resistance, toughness, and strength. This is particularly useful in applications that require tools to handle extremely hard materials, such as in aerospace or automotive industries.

-

Cemented Carbide Molds:

- Titanium-aluminum alloy coatings are also used in molds made from cemented carbide. These molds, used in the metal casting process, benefit from the enhanced wear resistance and corrosion resistance provided by the titanium-aluminum coatings, which contribute to longer service life and improved product quality.

-

Powder Metallurgy Parts of Superhard Materials:

- Titanium-aluminum alloys are essential in producing superhard materials through powder metallurgy. The coatings improve the hardness, thermal stability, and corrosion resistance of the final products, making them suitable for applications in industries such as mining, drilling, and cutting tools.

-

Metal Composite Ceramics:

- These alloys are often used as additives in the manufacturing of metal composite ceramics. The combination of metal and ceramic properties provides materials with enhanced strength, heat resistance, and electrical conductivity, making them suitable for demanding applications in electronics and mechanical systems.

-

Additives for High-Temperature Resistant Alloys:

- Titanium-aluminum alloys serve as key additives in the production of high-temperature resistant alloys. These alloys are commonly used in applications such as jet engines, gas turbines, and heat exchangers, where thermal stability and strength are critical. The addition of titanium and aluminum improves the overall temperature resistance and structural integrity of the alloy.

2. The main performance requirements of the target

(1) Purity Purity is one of the main performance indicators of the target, because the purity of the target has a great influence on the performance of the film. However, in practical applications, the purity requirements of the target materials are also different. For example, with the rapid development of the microelectronics industry, the size of silicon wafers has grown from 6 ", 8" to 12 ", and the wiring width has been reduced from 0.5um to 0.25um, 0.18um or even 0.13um, the previous target purity of 99.995% Can meet the technical requirements of 0.35umIC, and the preparation of 0.18um lines requires 99.999% or even 99.9999% for the purity of the target.

(2) Impurity content Impurities in the target solid and oxygen and water vapor in the pores are the main sources of pollution for the deposited film. Different targets have different requirements for different impurity contents. For example, pure aluminum and aluminum alloy targets used in the semiconductor industry have special requirements for alkali metal content and radioactive element content.

(3) Density In order to reduce the pores in the solids of the target and improve the performance of the sputtered film, the target is usually required to have a higher density. The density of the target not only affects the sputtering rate, but also affects the electrical and optical properties of the film. The higher the target density, the better the film performance. In addition, increasing the density and strength of the target allows the target to better withstand the thermal stress during sputtering. Density is also one of the key performance indicators of the target.

(4) Grain size and grain size distribution The target material is usually polycrystalline, and the grain size can be on the order of microns to millimeters. For the same target material, the sputtering rate of the target with fine grains is faster than that of the target with coarse grains; the thickness of the film deposited by sputtering the target with a small difference in grain size (uniform distribution) is more uniform .

Titanium in Medical Uses

Titanium, especially Grade 1 and Grade 2, is highly regarded in medical and biomedical fields for its biocompatibility, strength, and lightweight characteristics. It's commonly used in medical devices because it is not harmful to the body and is not likely to cause allergic reactions.

Key Medical Uses of Titanium:

- Orthopedic Implants: Titanium is commonly used in bone screws, plates, joint replacements, and spinal implants because it mimics the properties of bone.

- Dental Implants: Titanium's biocompatibility and strength make it a perfect choice for dental implants that require high durability and resistance to corrosion.

- Medical Instruments: Due to its corrosion resistance, surgical tools, needles, scalpels, and other medical instruments are often made from titanium or titanium alloys.

- Prosthetics: Titanium is used in the production of prosthetic limbs and implants for its combination of lightweight and strength.

- Cardiovascular Devices: Titanium is used in the production of pacemaker cases, stents, and valves due to its non-reactive nature in the human body.

- Wear-resistant coatings: Titanium sputtering targets can be used to deposit thin coatings on medical devices to enhance wear resistance, reduce friction, and improve biocompatibility.

Titanium Grades:

| Chemical requirements |

| | N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal

|

Titanium is a highly versatile metal, and it is categorized into various grades based on its composition and properties. These grades are generally classified into three main categories: Commercially Pure (CP) Titanium, Titanium Alloys, and Specialty Titanium Alloys. Here’s an overview of the most common titanium grades:

1. Commercially Pure (CP) Titanium

Commercially Pure titanium is the most basic form of titanium with minimal alloying elements. It is typically used in applications requiring excellent corrosion resistance and biocompatibility, but it does not have the high strength of titanium alloys.

-

Grade 1 (CP1):

- Composition: Minimum 99.5% titanium, with very small amounts of iron and oxygen.

- Properties: Grade 1 is the softest and most ductile of the commercially pure grades. It offers excellent corrosion resistance, especially in highly corrosive environments like seawater.

- Applications: Chemical processing, marine applications, medical implants, aerospace components.

-

Grade 2 (CP2):

- Composition: Minimum 99.2% titanium.

- Properties: Grade 2 has slightly higher strength than Grade 1, while still retaining excellent corrosion resistance. It is the most widely used commercially pure titanium grade.

- Applications: Heat exchangers, aerospace, medical devices (implants, surgical instruments), and marine applications.

-

Grade 3 (CP3):

- Composition: Minimum 99% titanium.

- Properties: Offers higher strength than Grade 2 but with slightly reduced formability.

- Applications: Chemical processing, marine, power generation, and medical applications.

-

Grade 4 (CP4):

- Composition: Minimum 98.5% titanium.

- Properties: The strongest of the commercially pure grades, offering excellent strength-to-weight ratio. It has a slightly lower corrosion resistance compared to Grade 2 but is still excellent for most industrial and medical uses.

- Applications: Aerospace, chemical industry, marine, medical implants, automotive components.

2. Titanium Alloys

Titanium alloys are generally stronger than commercially pure titanium and have enhanced properties, such as improved strength, better fatigue resistance, and sometimes superior corrosion resistance. These alloys are typically categorized by the elements alloyed with titanium, such as aluminum, vanadium, molybdenum, iron, or zirconium.

Alpha Alloys

These titanium alloys are primarily alloyed with aluminum and offer excellent strength and corrosion resistance at high temperatures. They have a high alpha phase content.

-

Grade 5 (Ti-6Al-4V):

- Composition: 90% titanium, 6% aluminum, 4% vanadium.

- Properties: One of the most widely used titanium alloys, Grade 5 offers an excellent balance of strength, light weight, and corrosion resistance. It is also heat-treatable to further enhance its mechanical properties.

- Applications: Aerospace (aircraft, rockets), medical implants (orthopedic and dental), marine, power generation, and sports equipment.

-

Grade 6 (Ti-5Al-2.5Sn):

- Composition: 5% aluminum, 2.5% tin, and the balance titanium.

- Properties: Offers better weldability than Grade 5 and is used for high-temperature applications where some corrosion resistance is still required.

- Applications: Aerospace components, high-temperature applications, gas turbine engines.

Beta Alloys

Beta alloys have higher amounts of beta-phase stabilizers (such as vanadium, molybdenum, or chromium), which improve their strength, formability, and resistance to high-temperature oxidation. They are generally used in applications requiring high strength.

Alpha-Beta Alloys

These alloys are a mix of both alpha and beta phases and offer a balance of strength, formability, and corrosion resistance. The alpha-beta alloys are the most commonly used titanium alloys in structural and high-performance applications.

- Grade 23 (Ti-6Al-4V ELI):

- Composition: 6% aluminum, 4% vanadium, with extra low interstitial elements such as carbon, oxygen, and nitrogen.

- Properties: This is the extra low interstitial (ELI) version of Grade 5. It offers improved biocompatibility, making it particularly useful for medical implants. Grade 23 is known for its excellent strength-to-weight ratio and superior fatigue resistance.

- Applications: Orthopedic implants, aerospace, dental implants, and sports equipment.

3. Specialty Titanium Alloys

These alloys are specifically developed for niche applications that require very specific properties.

-

Grade 7 (Ti-0.15Pd):

- Composition: Titanium with 0.12-0.25% palladium.

- Properties: Known for its superior corrosion resistance in highly acidic environments, especially in chloride-containing environments. It’s also more biocompatible than other alloys, making it suitable for medical applications.

- Applications: Medical devices, aerospace, chemical processing, and marine applications.

-

Grade 11 (Ti-0.3Pd):

- Composition: 0.3% palladium, and the balance titanium.

- Properties: Similar to Grade 7, with slightly higher palladium content for enhanced corrosion resistance. It is typically used in more demanding environments.

- Applications: Aerospace, chemical processing, and marine environments.

-

Grade 13 (Ti-0.3Ni):

- Composition: 0.3% nickel and titanium.

- Properties: Offers good corrosion resistance and is used in applications that require high strength and excellent performance in certain chemical environments.

- Applications: Marine applications, chemical processing.

| Tensile requirements |

| Grade | Tensile srength(min) | Yeild strength(mm) | Elongation(%) |

| | KSI | MPa | Ksi | MPa | |

| 1 | 35 | 240 | 20 | 138 | 24 |

| 2 | 50 | 345 | 40 | 275 | 20 |

| 5 | 130 | 895 | 120 | 828 | 10 |

| 7 | 50 | 345 | 40 | 275 | 20 |

| 12 | 70 | 438 | 50 | 345 | 18

|

4. Purpose

It is widely used in decorative coatings, wear-resistant coatings, CDs and VCDs in the electronics industry, as well as various magnetic disk coatings.

Tungsten-titanium (W-Ti) films and tungsten-titanium (W-Ti) -based alloy films are high-temperature alloy films with a series of irreplaceable excellent properties. Tungsten has properties such as high melting point, high strength and low coefficient of thermal expansion. W / Ti alloy has low resistance coefficient, good thermal stability and oxidation resistance. Such as various devices require metal wiring that plays a conductive role, such as Al, Cu, and Ag have been widely used and researched. However, the wiring metal itself is easily oxidized, reacts with the surrounding environment, and has poor adhesion to the dielectric layer. It is easy to diffuse into the substrate materials of devices such as Si and SiO2, and it will form metal and Si at a lower temperature. Compounds, which act as impurities, greatly degrade the performance of the device. The W-Ti alloy is easy to be used as a wiring diffusion barrier due to stable thermomechanical properties, low electron mobility, high corrosion resistance and chemical stability, especially suitable for use in high current and high temperature environments .

Conclusion:

Titanium alloy sputtering targets, including TiAl alloys, are versatile materials widely used for coating applications in industries ranging from aerospace to electronics and biomedical. These materials provide exceptional properties such as strength, corrosion resistance, biocompatibility, and wear resistance, making them ideal for demanding applications that require durable, high-performance thin films. When choosing a titanium sputtering target, factors like alloy composition, purity, and target geometry must be considered to achieve optimal results in the sputtering process.