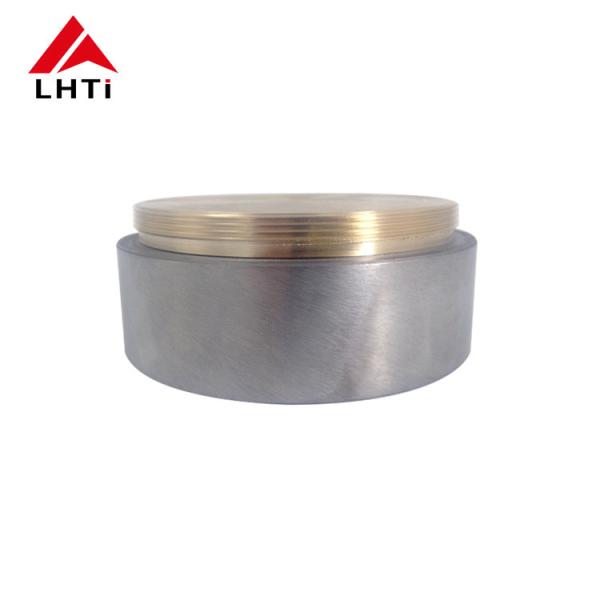

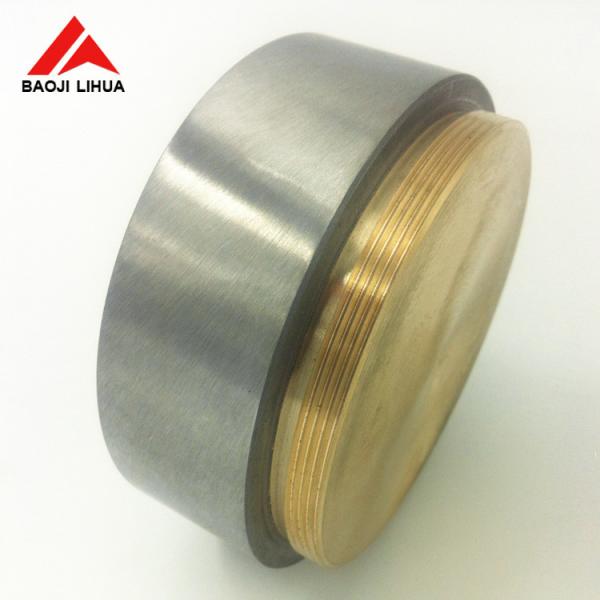

Sputtering Targets Grey Silver Ti Titanium Target to High Purity Sputtering in Medical Industry

Titanium Sputter Targets: Key Materials in Advanced Coating Technologies

Titanium sputter targets are essential in various high-tech applications, providing superior coatings that enhance the performance and longevity of numerous products. These targets are widely utilized across industries, including electronics, semiconductors, and military aerospace, where precision is paramount.

The Importance of Titanium Sputter Targets

In the realm of electronic components—such as CD storage media, semiconductor diodes, and liquid crystal displays—applying thin films of materials is crucial for enhancing functionality and performance. These films play a pivotal role in ensuring optimal device operation, including aspects like electrical conductivity, thermal management, and overall durability. Titanium sputter targets are particularly valuable because they facilitate the precise deposition of these films, which serve essential functions such as corrosion resistance, wear resistance, and improved adhesion. Unlike traditional coating methods, which often struggle to achieve the micron and nanometer precision required in modern applications, titanium sputter targets enable manufacturers to meet stringent specifications.

This precision is vital not only for consumer electronics but also for advanced applications in fields like telecommunications and aerospace, where even minor deviations can lead to significant performance issues. The ability to create uniform, high-purity films with consistent thickness across large areas makes titanium sputter targets indispensable in producing high-quality electronic components. Moreover, as technology continues to evolve and the demand for smaller, more efficient devices grows, the importance of these targets will only increase. Their versatility and effectiveness in a wide range of applications—from smart devices to cutting-edge nanotechnology—underscore their role as a preferred choice for manufacturers looking to enhance their products' reliability and longevity in an increasingly competitive market.

Composition and Types

Titanium sputter targets come in various materials and alloys, including:

- Gr1, Gr2, Gr5 Titanium

- TiAl (Titanium Aluminum)

- TiCr (Titanium Chromium)

- TiCu (Titanium Copper)

- TiSi (Titanium Silicon)

- Zirconium

- Chrome

- Molybdenum

Each type offers distinct advantages depending on the specific requirements of the application, such as electrical conductivity, thermal stability, and hardness.

Characteristics of Titanium Sputter Targets

For optimal performance, titanium sputter targets must meet several critical criteria:

- High Purity: Ensures minimal contamination during the deposition process.

- Uniform Crystal Grains: Promotes consistent film quality across the surface.

- Good Compactness: Enhances durability and stability during sputtering.

These characteristics make titanium sputter targets ideal for high-performance applications where precision and reliability are essential.

Common Sizes and Customization

Standard sizes for titanium sputter targets include:

- Φ100*40 mm

- Φ98*40 mm

- Φ95*45 mm

- Φ90*40 mm

- Φ85*35 mm

- Φ65*40 mm

Manufacturers also offer customization options based on customer specifications or drawings, ensuring that the targets meet specific operational needs.

| Technical Parameters | Description |

| Product Name | Titanium Disc |

| Material | Titanium Alloy |

| Shape | Round |

| Thickness | 35mm-550mm Or As Your Requirement |

| Diameter | 150mm-1300mm Or As Your Requirement |

| Color | Silver |

| Surface Treatment | Polished |

| Application | Industrial |

| Package | Plywood Case Or According to Your Requirement

|

Understanding High Purity Titanium

Composition and Properties

High purity titanium is a lightweight, durable metal known for its exceptional mechanical strength and resistance to corrosion, making it a preferred material in various demanding environments, including medical applications. The purity of titanium plays a crucial role in its performance, especially in contexts where the material interacts with sensitive biological systems.

Titanium’s unique combination of properties—such as biocompatibility, resistance to body fluids, and non-toxicity—make it ideal for medical devices, where the material must safely coexist with the human body without causing adverse reactions. The high purity version of titanium ensures minimal impurity content, which is particularly important in high-precision applications such as implants or surgical tools, where even trace impurities could negatively impact performance.

Key Characteristics of High Purity Titanium Sputtering Targets

High purity titanium sputtering targets are manufactured to meet rigorous standards, providing a range of features that enhance their effectiveness in medical applications:

-

High Purity Levels:

- Titanium used for sputtering is typically of 99.99% purity or higher, which is critical in medical devices. Even small amounts of impurities can compromise the biocompatibility of the material, potentially leading to tissue rejection or allergic reactions. High purity ensures that the material interacts with the human body without releasing harmful substances.

-

Fine Particle Size:

- The fine particle size of high purity titanium sputtering targets contributes to more precise deposition during the sputtering process. This results in smooth, uniform coatings that are essential for high-performance medical devices. For example, when applied to implants, these coatings provide better surface bonding with bone tissue and reduce the risk of implant rejection or failure.

-

Ease of Sintering:

- High purity titanium targets sinter more effectively, creating dense and uniform coatings essential for producing high-quality medical devices. This property ensures that the thin films deposited during the sputtering process are consistent and uniform, which is critical for maintaining device performance over time. For example, dental implants or orthopedic devices benefit from sintered coatings that help enhance osseointegration (the integration of the implant with bone tissue).

-

Excellent Formability:

- Titanium is a highly formable material, and high purity versions allow for even greater flexibility in creating complex shapes. In the medical industry, this is particularly beneficial for manufacturing intricate medical instruments such as surgical tools, stents, and catheters. High purity titanium sputtering targets can be shaped and deposited onto a variety of substrates, ensuring compatibility with different medical device designs.

Applications of High Purity Titanium Sputtering Targets in the Medical Industry

High purity titanium sputtering targets are widely used in various medical applications. Their ability to form high-quality thin films plays a significant role in improving the performance of medical devices. Here are some key areas where these sputtering targets are applied:

1. Medical Implants

Titanium is widely used in the production of medical implants such as hip replacements, knee implants, dental implants, and spinal devices. The high purity titanium sputtering targets are used to create bioactive coatings on the surface of these implants. These coatings enhance osseointegration, helping implants bond better with the bone. The biocompatibility of titanium ensures that it is safe to use in direct contact with body tissues, while the sputtering process provides a means of applying precise, uniform coatings that improve the device's performance.

2. Surgical Instruments

Surgical instruments, such as scalpels, forceps, and scissors, benefit from high purity titanium coatings that improve their durability and resistance to corrosion. The sputtered titanium films provide enhanced hardness, making the instruments resistant to wear and degradation. Moreover, the coatings reduce friction, making it easier for the instruments to glide over tissues and perform more effectively during surgeries. These properties also make the tools easier to clean and sterilize.

3. Stents and Catheters

High purity titanium coatings are also applied to vascular stents and catheters. Titanium’s corrosion resistance ensures that these devices maintain their integrity when in contact with bodily fluids. Additionally, the thin titanium films applied to these devices can improve their mechanical properties, such as flexibility and strength. This is essential for devices like stents, which must navigate the blood vessels and remain securely in place without degrading over time.

4. Diagnostic Equipment

High purity titanium sputtering targets are used in the creation of coatings for diagnostic tools like sensors, medical imaging devices, and endoscopes. Titanium coatings can help these devices resist corrosion, remain sterile, and last longer in harsh medical environments. Additionally, titanium coatings can provide bioactive properties that enhance the functionality of medical devices, enabling better tissue interaction and more accurate diagnostics.

5. Bioactive Coatings for Tissue Engineering

In the field of tissue engineering, titanium sputtering targets are used to deposit bioactive titanium coatings on scaffolds and devices designed to support tissue regeneration. These coatings improve the scaffold's ability to support cell adhesion, proliferation, and differentiation, thereby enhancing the effectiveness of the scaffold in tissue repair and regeneration.

Titanium Grades for Sputtering and Medical Applications

Titanium, due to its unique combination of properties such as biocompatibility, strength, light weight, and corrosion resistance, is widely used in both medical applications and sputtering processes. Understanding the various grades of titanium is essential for selecting the appropriate material for specific applications, particularly in the high-precision, high-performance environments found in the medical industry. In this article, we will explore the different titanium grades suitable for sputtering and their medical applications.

1. Titanium Grades Overview

Titanium grades are typically categorized into two main types:

-

Commercially Pure Titanium (CP Titanium): This grade consists of pure titanium with varying levels of oxygen content. It is highly resistant to corrosion and is commonly used in applications where biocompatibility and resistance to body fluids are critical.

-

Titanium Alloys: These grades are alloyed with other elements (such as aluminum, vanadium, or molybdenum) to enhance specific properties, such as strength, formability, and heat resistance. Titanium alloys are used in situations where higher mechanical properties are required.

2. Titanium Grades for Sputtering

Sputtering is a physical vapor deposition (PVD) process where a target material, typically in the form of a solid metal, is bombarded with energetic ions to deposit thin films onto substrates. Titanium sputtering targets are used to create coatings that are essential for enhancing the performance of medical devices, electronic components, and other high-tech applications.

a. Grade 1 (CP-Titanium Grade 1)

- Purity: 99.5% titanium (Commercially Pure)

- Properties: Grade 1 is the softest and most ductile of all titanium grades, offering excellent corrosion resistance and outstanding weldability. It has low strength but is highly formable.

- Applications: Grade 1 is suitable for thin film deposition via sputtering in applications requiring high biocompatibility. It is used in medical implants, dentistry, and surgical instruments, where the material must be highly resistant to body fluids and easy to shape.

b. Grade 2 (CP-Titanium Grade 2)

- Purity: 99.2% titanium (Commercially Pure)

- Properties: Grade 2 is stronger than Grade 1, while still offering excellent corrosion resistance. It is the most commonly used grade in medical and aerospace applications.

- Applications: Grade 2 is frequently used in medical implants like hip and knee replacements, spinal implants, dental implants, and surgical instruments. Its high resistance to corrosion and excellent mechanical properties make it ideal for body contact applications. As a sputtering target, it is often used for coating stents, catheters, and other medical devices.

c. Grade 3 (CP-Titanium Grade 3)

- Purity: 99.0% titanium (Commercially Pure)

- Properties: Grade 3 is stronger than Grade 2 and offers a balance between strength, corrosion resistance, and formability. It is still considered commercially pure but has slightly higher amounts of impurities.

- Applications: While not as commonly used as Grade 2 in medical applications, Grade 3 may still be used for medical implants and orthopedic devices, especially when higher mechanical strength is needed. It is also used in sputtering targets for thin film coatings that require strength and durability.

d. Grade 4 (CP-Titanium Grade 4)

- Purity: 99.0% titanium (Commercially Pure)

- Properties: Grade 4 is the strongest of the commercially pure grades. It offers higher strength than Grades 1, 2, and 3 but still maintains a relatively high level of corrosion resistance. It is the most used of the commercially pure grades in the medical field for demanding applications.

- Applications: Grade 4 is widely used for surgical implants, bone screws, dental implants, and vascular devices where both strength and biocompatibility are critical. It is also used in sputtering applications for medical devices that require enhanced mechanical properties and biocompatibility.

e. Grade 5 (Ti-6Al-4V) - Titanium Alloy

- Composition: 90% titanium, 6% aluminum, 4% vanadium

- Properties: Grade 5 is the most commonly used titanium alloy. It is known for its excellent strength-to-weight ratio, high mechanical strength, and relatively good corrosion resistance. However, it is not as corrosion-resistant as the commercially pure grades.

- Applications: Grade 5 is widely used for high-strength orthopedic implants, dental implants, aerospace components, and surgical instruments. Due to its strength and ability to be machined into complex shapes, it is used in devices requiring superior mechanical properties, such as hip replacements and knee implants. In sputtering, Grade 5 is used for applications that require a robust, high-performance coating, particularly in high-stress medical environments.

f. Grade 9 (Ti-3Al-2.5V) - Titanium Alloy

- Composition: 94.5% titanium, 3% aluminum, 2.5% vanadium

- Properties: Grade 9 is a lower-strength titanium alloy compared to Grade 5 but offers a better balance of formability and strength. It has good corrosion resistance and is highly resistant to fatigue.

- Applications: This alloy is often used in vascular implants, stents, and orthopedic applications that require a combination of strength, formability, and corrosion resistance. It is also used in sputtering targets for coating medical devices like catheters and surgical instruments.

3. Medical Applications of Titanium Grades

Titanium's biocompatibility, low toxicity, and resistance to corrosion make it the material of choice for many medical applications, including:

1. Medical Implants

- Grade 2 and Grade 4 titanium are commonly used for dental implants, hip and knee replacements, spinal implants, and bone screws. Their corrosion resistance and mechanical properties make them ideal for long-term body contact.

- Grade 5 is often used for high-strength implants where enhanced mechanical properties are required, such as in hip replacements or orthopedic devices.

2. Surgical Instruments

- Grades 2 and 4 are widely used for surgical instruments such as forceps, scalpels, scissors, and scalpels, providing excellent corrosion resistance and durability.

3. Cardiovascular Devices

- Grade 5 and Grade 9 are frequently used for vascular stents, catheters, and vascular grafts, where flexibility and strength are critical for device performance.

4. Prosthetics

- Grade 5 and Grade 9 are used for the fabrication of prosthetic joints and bone prostheses, where strength, fatigue resistance, and long-term durability are essential.

5. Sputtering Applications in Medical Device Manufacturing

Titanium sputtering targets are used to apply thin titanium coatings onto medical devices to improve their properties. Titanium coatings provide:

- Bioactive surfaces that improve osseointegration in implants.

- Corrosion resistance for stents, catheters, and other devices exposed to bodily fluids.

- Enhanced wear resistance for implants such as knee or hip replacements.

Grades 1, 2, 4, and 5 are commonly used in sputtering applications, depending on the specific requirements for mechanical properties, corrosion resistance, and biocompatibility.

Titanium in Medical Uses

Titanium, especially Grade 1 and Grade 2, is highly regarded in medical and biomedical fields for its biocompatibility, strength, and lightweight characteristics. It's commonly used in medical devices because it is not harmful to the body and is not likely to cause allergic reactions.

Key Medical Uses of Titanium:

- Orthopedic Implants: Titanium is commonly used in bone screws, plates, joint replacements, and spinal implants because it mimics the properties of bone.

- Dental Implants: Titanium's biocompatibility and strength make it a perfect choice for dental implants that require high durability and resistance to corrosion.

- Medical Instruments: Due to its corrosion resistance, surgical tools, needles, scalpels, and other medical instruments are often made from titanium or titanium alloys.

- Prosthetics: Titanium is used in the production of prosthetic limbs and implants for its combination of lightweight and strength.

- Cardiovascular Devices: Titanium is used in the production of pacemaker cases, stents, and valves due to its non-reactive nature in the human body.

- Wear-resistant coatings: Titanium sputtering targets can be used to deposit thin coatings on medical devices to enhance wear resistance, reduce friction, and improve biocompatibility.

Titanium Grades:

| Chemical requirements |

| | N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal

|

| Tensile requirements |

| Grade | Tensile srength(min) | Yeild strength(mm) | Elongation(%) |

| | KSI | MPa | Ksi | MPa | |

| 1 | 35 | 240 | 20 | 138 | 24 |

| 2 | 50 | 345 | 40 | 275 | 20 |

| 5 | 130 | 895 | 120 | 828 | 10 |

| 7 | 50 | 345 | 40 | 275 | 20 |

| 12 | 70 | 438 | 50 | 345 | 18

|

Conclusion:

Titanium alloy sputtering targets, including TiAl alloys, are versatile materials widely used for coating applications in industries ranging from aerospace to electronics and biomedical. These materials provide exceptional properties such as strength, corrosion resistance, biocompatibility, and wear resistance, making them ideal for demanding applications that require durable, high-performance thin films. When choosing a titanium sputtering target, factors like alloy composition, purity, and target geometry must be considered to achieve optimal results in the sputtering process.