Renewable Paper Molded Machine For Making Egg Carton Fruit Tray Coffee Cup Tray

Description:

The egg box production line is composed of pulping system, reciprocating forming machine, drying line and hot press machine. By using waste paper such as newspaper, carton paper, office paper, paper scrap and other waste paper as raw materials, the production line is capable of producing egg boxes, fruit trays, beverage trays wine trays, coffee cup tray, medical care products.

Specification:

| Capacity | 800-1000pcs per hour |

| Feeding raw material | Waste paper |

| Operator Required | 3~5 people/shift |

| Drying Method | Dry in mold, thermal forming |

| Forming Method | Vacuum forming |

| Electricity consumption | 40-50 kw |

| Water consumption | 0.4-0.5ton/h |

| Control | PLC+ Touch screen |

| Machine Material | All parts in contact with water is SS304 Stainless Steel |

Q & A

WHAT WE DO

1. Diversified pulp molding production line for egg tray, egg carton, fruit tray, cup carrier, industrial package, disposable tableware, medical care products ,etc. 2. Rich specifications of pulp molding matching mold, offer the molds for egg tray, egg carton, fruit tray, cup carrier, industrial package, disposable tableware, medical care products, etc. 3. Various pulp molding tableware products: paper plate, sugarcane disposable lunch box, paper bowl etc.

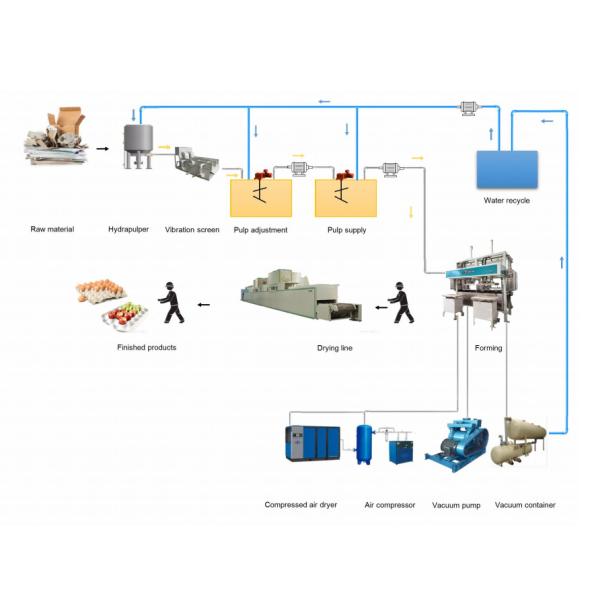

Production Working Process:

Illustrations of Machine & Product: