Q & A:

Illustrations of Machine & Product:

Paper Pulp Forming Machine To Produce Packaging With Customize Dimension

Description:

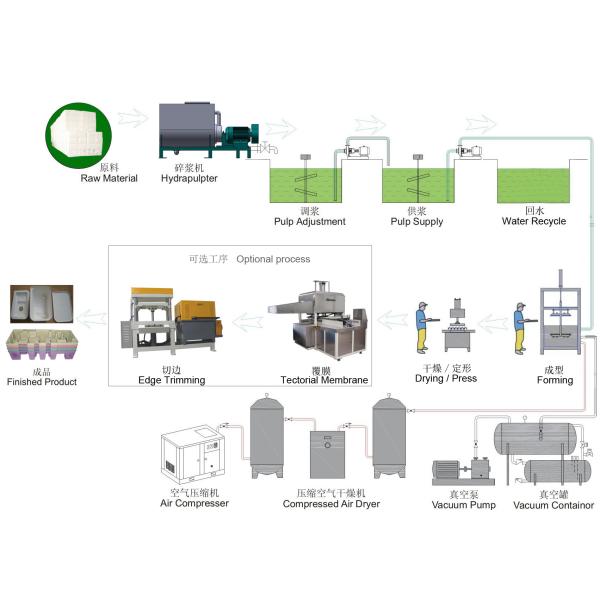

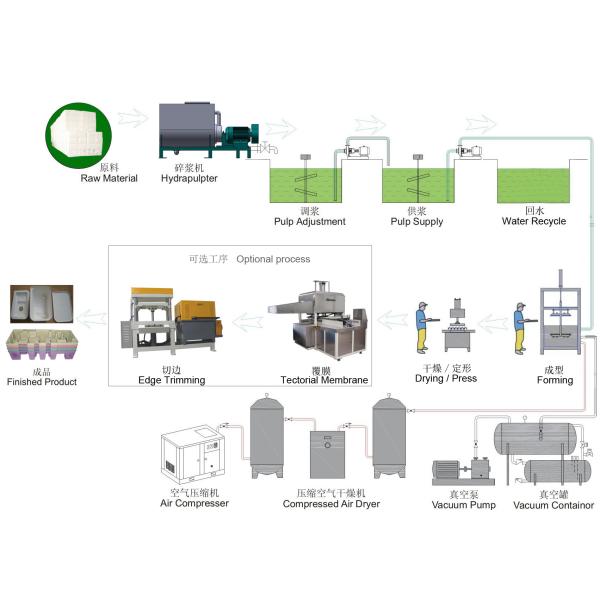

There are different designs of molding dies. These dies matter in the quality and shape of the product. Generally, there are two types of pulp molding machines – Forming mold and Transfer mold.

The forming mold is used to shape the prepared pulp as required. Whereas, the transfer mold aims to help to get the wet pulp products out from the forming mold.

By using virgin pulp ( surgarcane bagasse, bamboo pulp, wood pulp, straw pulp) , this reciprocating forming machine & wet hot pressing machine are capable of making all kinds of pulp molding industrial package for electronic product, cosmetics products, high-end liquor packaging and crafts, etc

The whole production is under automatic control via HIM, processes of forming, wet hot pressing, and trimming and stacking run continually,

Our machine select high quality electronic devices and pneumatic components and are fully designed by computer assistant engineering and high technology. It has been proven high efficiency, low maintenance and energy saving.

Specification:

| Capacity | 60-250kg/ hr |

| Feeding raw material | Virgin pulp ( bagasse pulp/bamboo pulp/wood pulp/straw pulp) |

| Workshop Requirement | 1000~ 1800㎡ |

| Operator Required | 4 -5 workers/ shift |

| Drying Method | Dry in mold, thermal forming |

| Forming Method | Vacuum forming |

| Electricity consumption | 180-400kw/hr |

| Water consumption | 1-2 tons/hr |

| Control | PLC+ Touch screen |

| Machine Material | All parts in contact with water is SS304 Stainless Steel |

Q & A:

Illustrations of Machine & Product: