Double tanks forming machine to produce high quality package

Molded pulp is often considered a sustainable tableware material, unlike plastic material, molded pulp is produced from natural fiber, which can be recycled again after its life-cycle of 3-4 months degradable by landfill.

By using virgin pulp ( surgarcane bagasse, bamboo pulp, wood pulp, straw pulp) , this reciprocating forming machine & wet hot pressing machine are capable of making all kinds of pulp molding industrial package for electronic product, cosmetics products, high-end liquor packaging and crafts, etc

This reciprocating forming machine can manufacture multiple different pulp tray with different mould at the same time, since two forming sections are separated and can work independantly.

In addition, a robot arm is optional if you want the production to be full automatic.

| Technical Description |

| Capacity | 60-250kg/ hr |

| Feeding raw material | Virgin pulp ( bagasse pulp/bamboo pulp/wood pulp/straw pulp) |

| Workshop Requirement | 1000~ 1800㎡ |

| Operator Required | 8~10 staffs/shift for semi-auto 5~8 staffs/shift for full auto |

| Machine Material | All parts in contact with water is SS304 Stainless Steel |

| Forming Method | Vacuum forming |

| Electricity consumption | 180-400kw/hr |

| Water consumption | 1-2 tons/hr |

| | |

Feature

- Forming, wet pressing processes independently

- Robot arms is optional to meet the requirement of customer

- Flexible machine setting, according to the automation requirement

- More choice on the layout design to match different plant size

- Low machine investment to start-up business

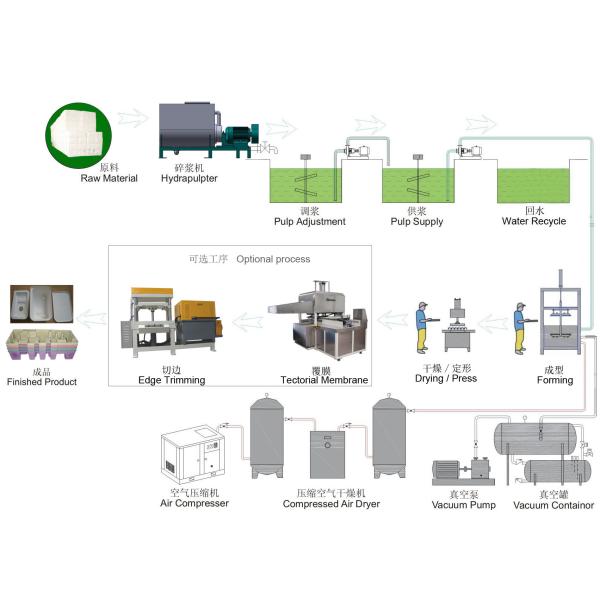

Production Working Process

Application: