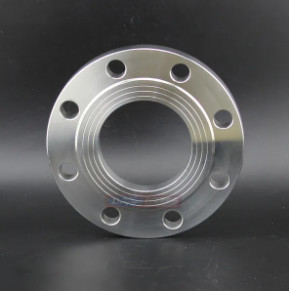

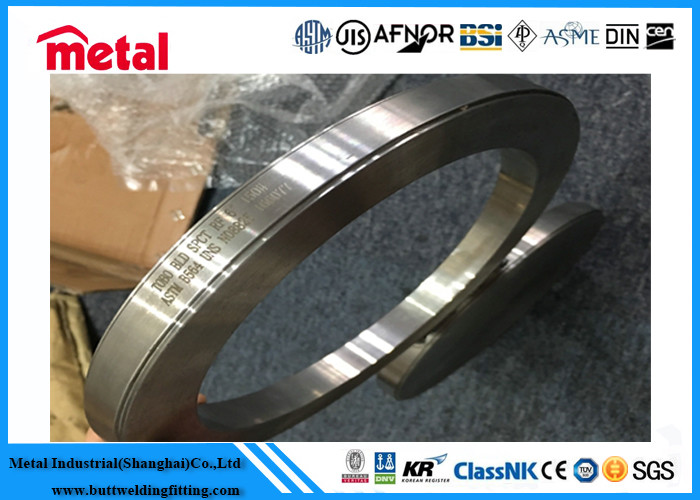

Professional Hubbed Slip-On Welding Flange Nickel Alloy B564 N04400 6"150#

| flangeType | Professional Hubbed Slip-On Welding Flange Nickel Alloy B564 N04400 6"150# |

| Standard | ASME/ANSI B16.5 |

| Size | 1/2’’~60’’ |

| Pressure Rate | 150lb to 2500lb |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Material | Alloy |

| Allloy steel flange | ASTM A182 F5; F11;F22;F91;F51 ASTM A350 LF1; LF2; A350 LF3 ;LF4;LF6;LF8 |

| Stainless Steel flange | ASTM A182 F304/304H/304L ASTM A182 F316/316H/316L ASTM A182 F321/321H ASTM A182 F347/347H |

| Nickel Alloys Flanges | Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276 |

| Copper Alloys Flange | Copper, Brass & Gunmetal |

| Package | Wooden cases, pallets, nylon bags or according to the customers' requirements |

| MOQ | 1pcs |

| Delivery time | 10-100 days depending on quantity |

| Payment terms | T/T or Western Union or LC |

| Shipment | FCA Tianjin/Shanghai, CFR, CIF, etc |

| Application | Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc |

| Remarks | Other materials and drawings are available. |

The bore size of a slip-on flange is larger than the outside diameter of the connecting pipe, as the pipe has to slide inside the flange to be connected by the execution of a fillet weld. Slip-on flanges are also defined “Hubbed Flanges” and they are easy to recognize due to their slim and compact

Other Products

Threaded Flange is similar to slip-on flange. However, it has a screw thread of female screw on the bore of the flange. The most important advantages are that the threaded flange can be bonded without welding and used in highly explosive areas with danger or low-pressure process and welding at toom temperature.

Value Added Services

· Hot Dip Galvanizing ,

· Epoxy Coating.

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1B