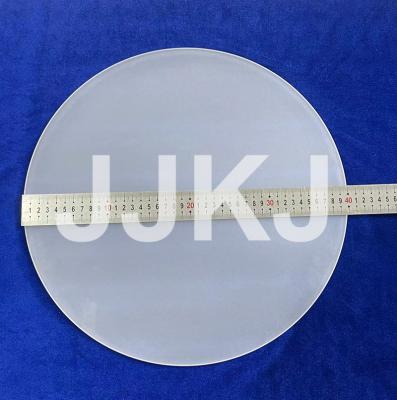

Clear Aperture Top Grade Large Sapphire Crystal Surface Coated Crystal 60/40 in C axis Orientation

WHY ARE SAPPHIRE WINDOWS SUCH HIGH PERFORMERS?

Sapphire windows and flat stock are incredibly hard, strong and wear resistant:

A sapphire window can be exposed to extreme abradants such as sand and particulates with minimal effect on the clarity of the window. This makes sapphire windows the ideal material for a variety of applications such as: Aerospace windows, downhole and drilling vision systems, inspection windows, watch crystals and gun sights.

Sapphire windows can take pressure like no other clear material, making sapphire windows the go-to transparent material for high-pressure vessels, deep sea windows and sight glasses. Combined with the exceptional thermal and chemical performance of sapphire, a sapphire window is the ideal transparency for pressurized in-process, deep sea and equipment sensors.

Sapphire flats and wear parts are used in applications in which wear is a problem. Systems like canning machines, slide plates, V-blocks, flat bearings and pushers utilize sapphire flats and blocks to extend the lifetime of the equipment and reduce downtime.

Properties of Single Crystal Sapphire Window:

| Chemical formula | Al₂O₃ |

| Purity | 99.999% |

| Crystal structure | Hexagonal |

| Density | 3.98g/cm³ |

| Hardness Mohs | 9 |

| Diameter | 300+ mm |

| Diameter Tolerance | ±0.05 mm |

| Thickness | 5-100 mm |

| Thickness Tolerance | ±0.05 mm |

| Surface quality | DSP 60/40 |

| Clear aperture | 90% |

| Bevel | 0.1-0.3mmx45 degree |

Applications:

Optical Windows are flat, plane-parallel, transparent optical surfaces designed to protect sensors and other electronic

instruments from environment conditions.

Optical Window selection considerations include material transmission properties as well as scattering, strength and resistance to certain environments. Their use should not impact on magnification of a system. Optical Windows can be optically polished and incorporate an element for diffusing light source to control illumination.

AR coatings can be applied to ensure maximum transmission performance for a particular wavelength. The windows are made in a range of materials including UV Fused Silica, Quartz, IR Crystals and optical glasses. Our optical window properties include x-ray protection, non-browning to UV light and light transmission from deep ultra violet to far infrared.

Optical Windows products include wedges, substrates, discs, flats, plates, rods, protection windows, laser windows, camera windows, light guides and domes.

Our Windows are used by scientific and industrial companies across the world of medical, defence, instrumentation, laser, research and imaging.

All our Optical Windows can be supplied from a standard range stock. We also supply custom optical windows made to your specification, sizes and specific design.