Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

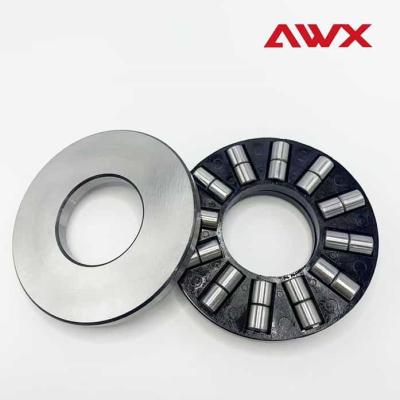

Thrust roller bearings comprise of bearing seats, shaft rings, rollers, and cages, out of which rollers are the central components. These rollers are situated between the bearing seats and shaft rings and are responsible for transmitting and dispersing axial loads by means of rolling. This design allows the thrust roller bearings to maintain a low friction coefficient while carrying high loads, thereby minimizing energy loss and increasing the life of the bearing.

Thrust roller bearings comprise of bearing seats, shaft rings, rollers, and cages, out of which rollers are the central components. These rollers are situated between the bearing seats and shaft rings and are responsible for transmitting and dispersing axial loads by means of rolling. This design allows the thrust roller bearings to maintain a low friction coefficient while carrying high loads, thereby minimizing energy loss and increasing the life of the bearing.