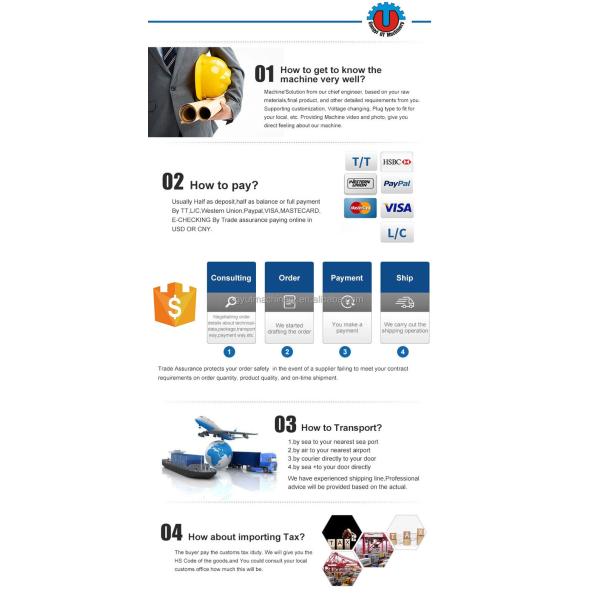

About Packing, for small size or single machine, we can offer free fumigation wooden case with steel frame, it not only can protect machine from damage, but also avoid checking when exporting.

For multiple machines or production line, it's better to loaded in standard container 20GP, 40GP, 40HQ, unually it needs wrapped with plasitc firstly, then loaded in container.

We can offer EXW, FOB and CIF terms.

EXW: You arrange the shipping details from our factory to your port by yourself.

FOB: We arrange freight transport to Qingdao, Shanghai or other ports of China, then you arrange the shipping details from China port to your country port.

CIF: We arrange all shipping details to your country port, and ensure machines smooth arrival.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)