Auto Sheet Loading & Unloading manipulator Exchange table CNC Fiber Laser Cutting Machine

Product Application,

Applied materials:

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied Industries:

Fiber laser cutting machine applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Technical characteristics,

The biggest advantages of machine help you choose most suitable one.

Available laser power range is 1000W-30000W.

1. We have tube welded table for economical solution, and plate welded table for heavy-duty applications, plate cutting, tube cutting both available.

2. Single table, double auto feeding table, with or without protective cover, both available.

3. We have professional CNC system designer, laser machine designer to meet all your customized request, offer professional and fast service.

4. Automatic feeding Robot is added to the laser cutting machine. Through pre-set program and one key operation, the sheet can be automatically sucked and transported from the stacking table to the cutting platform.

Structure of This Exchange Table Laser cutting machine,

1. Fully protected and enclosed design, more environmentally friendly

The whole machine is fully protected and closed design, safe and environmentally friendly, no pollution, in line with ergonomicsand international standards. The machine has multiple safety warning functions such as laser abnormal alarm, cutting abnormal alarm, gas low pressure alarm, chiller abnormal alarm, etc., to ensure stable and safe cutting of the machine.

2. Extruded aluminum gantry Beam

It adopts a gantry structure, a lightweight design, uses aerospace-grade extruded aluminum, and is finished after artificial aging and solution treatment. The gantry has excellent rigidity, surface quality, and integrity. It also has excellent dynamic performance and is conducive to high speed cutting.

3. Auto-focus laser cutting head

The machine is equipped with an automatic focusing laser head, the focus can be automatically adjusted, and the operation is simple, convenient, fast and accurate. Shorten piercing time, improve piercing quality, high-speed cutting, and saving time.

4. Operating software CYPCUT

● Real time display cutting trace and coordinate are available

● It enjoys high capacity of anti-jamming as well as high control accuracy

● Equipped with completed digital servo system

● It is well capable of self-diagnosis, self-adaptability

● Rapid change and file batching process

●. It deals with programs shortly

● It is well capable of anti-virus protection

● Automatic search edge function

● Break-point back function

● Backward function

● leapfrog function

● Edge-shared cutting

● Support varies codes

● The movement is steady

● Function of edit code

● Soft limit, alarm functions

5. Intelligent Dust removal system

The newly upgraded intelligent dust removal system has a more reasonable dust removal design, which effectively increases the ventilation and dust removal effect and prolongs the service life of the equipment

6. Auto Sheet Loading & Unloading Manipulator

Gantry type automatic servo loading and unloading manipulator adopts gantry + suction cup + double forks integrated into a single lifting platform to finish plate loading and unloading.

The user controls the touch screen to switch between automatic feeding mode and manual feeding mode, which is suitable for different working states.

Main technology parameters,

| Machine Name | Exchange Table CNC fiber laser cutting machine |

| Model | DF4020-8000W |

| power of laser | 8000w |

| laser source | MAX/RAYCUS/IPG |

| Laser wavelength | 1080nm |

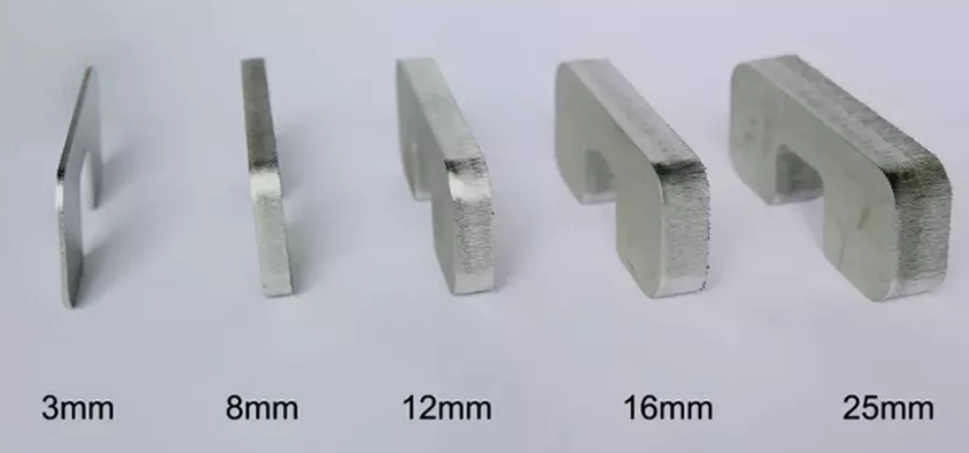

| Maxim Cutting Thickness | carbon steel(O2) | 25mm-28mm |

| stainless steel(N2) | 14mm-15mm |

| Aluminum sheet | 10mm-12mm |

| Brass sheet | 8mm |

| Maxim cutting speed | 120m/min(according to materials) |

| Max. acceleration | 1.2G |

| Energy instability | ≤2% |

| supported graphic formats | CAD,CorelDraw software,DXF/DWG/PLT |

| Cutting area | 4000×2000 |

| X axis travelling | 4000 |

| Y axis travelling | 2000mm |

| Z axis travelling | 250mm |

| accuracy of re-position | ±0.03mm/m |

| accuracy of position X/Y axis | ±0.05mm/m |

| Max. loading weight of workbench | 2000KG |

| Max. loading weight of Manipulator | 750kg |

| power of the machine | 350V-420V/50Hz |

| Weight of machine | 12500kg |

| Dimensions | 11800x3550x2600mm |

Main components,

| Name | Brief description | Brand of country |

| Fiber Laser | 8000W | MAX/RAYCUS/IPG |

| Optical system | MAX/RAYCUS/IPG | MAX/RAYCUS/IPG |

| Autofocus cutting head | Special cutting head for optical fiber | Raytools/Precitec |

| Dedicated cooling system | Double circulation system, heat exchange titanium tube, over temperature alarm, flow protection | Wuhan Hanli/Tongfei |

| Mechanical transmission system | Taiwan Hiwin high-precision high-speed rail Taiwan YYC rack and Pinion (helical) | Taiwan Hiwin Taiwan YYC |

| Deceleration system | INNOWELLE-FIEDLER/Alpha | Germany |

| Proportional Valve | SMC | Japan |

| Electrical installation | Schneider/ABB | France |

| Tracking sensor system | High precision automatic induction, accuracy 0.1 mm | Shanghai CYPCUT |

| Computer System | Special Industrial PC for laser | Taiwan Yanxiang |

| X-AXIS | SERVO unit | Yaskawa/Fuji, Japan Delta,Taiwan |

| Y-AXIS | SERVO unit | Yaskawa/Fuji, Japan Delta,Taiwan |

| Z-AXIS | SERVO unit | Yaskawa/Fuji, Japan Delta,Taiwan |

| Cutting software | Professional CNC cutting software | Shanghai CYPCUT |

| Nesting software | CypNest | Shanghai FSCUT |

| I / O card | 32 points | CYPCUT |

| Voltage Regulator | Optional | China |

| Cutting machine | Precision Gantry Exchange table | PSL |

| Auto Loading & Unloading Robot | 750KG | PSL |

| Power supply Regulator | | PSL |