What is Reverse Osmosis?

Reverse osmosis (R/O) is a water treatment process in which water is forced through a semi-permeable membrane that has very small holes or "pores". Clean water passes through and impurities that are too big to pass through the membrane are left behind and flushed away. In a word, it is a machine to make pure/ultra pure water.

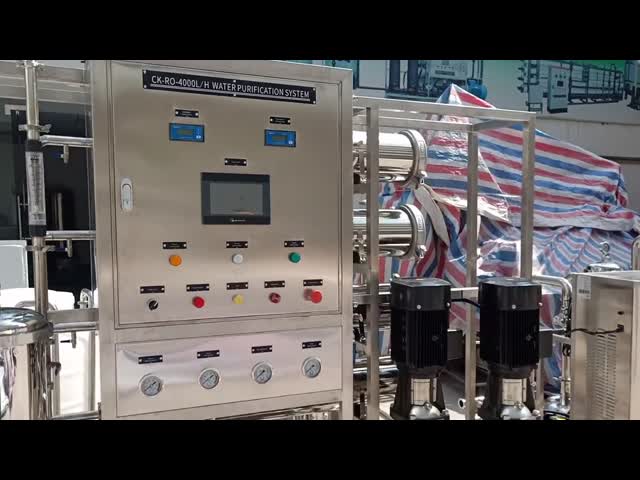

RO System Includes:

Feed Water Pump

Pretreatment Filter (according to your water anlysis report choose the Multi-media filter,Activated carbon filter,soften system )

PH Dosing system

Cartridge filter

CIP Clean System

High pressue pump

RO Membrane

Main Technical Parameters:

| Model | Flow rate (L/h) | Power(KW) | Water use efficiency | RO membrane | Dimension

L X W X H(mm) |

| RO-500L | 500 | 1.5 | ≥ 50% | 4040 | 1650X630X1800 |

| RO-750L | 750 | 2.5 | ≥ 50% | 4040 | 1870X630X1850 |

| RO-1000L | 1000 | 2.5 | ≥ 50% | 4040 | 1870X650X1850 |

| RO-2000L | 2000 | 3.5 | ≥ 50% | 4040 | 2440X650X1750 |

| RO-3000L | 3000 | 4 | ≥ 50% | 4040 | 2440X620X1850 |

| RO-5000L | 5000 | 7.5 | ≥ 50% | 8040 | 2000X900X1800 |

| RO-6000L | 6000 | 9.5 | ≥ 60% | 8040 | 3000X900X1800 |

| RO-8000L | 8000 | 13.5 | ≥ 60% | 8040 | 3000×900×1800 |

| RO-9000L | 9000 | 14 | ≥ 60% | 8040 | 4000X900X1800 |

| RO-10T | 10T/H | 19 | ≥ 60% | 8040 | 3000X900X1800 |

| RO-12T | 12T/H | 19.5 | ≥ 60% | 8040 | 4000X900X1800 |

| RO-15T | 15T/H | 23 | ≥ 60% | 8040 | 4000X900X1950 |

| RO-20T | 20T/H | 28 | ≥ 60% | 8040 | 5000X900X1950 |

| RO-30T | 30T/H | 55 | ≥ 60% | 8040 | 7000X900X1950 |

Flow Chart Of RO Water Treatment Machine

Raw water pump - Sand filter - Carbon filter -Cartridge filter - High pressure pump- RO membrane host-RO Cleaning system

1. Raw water supply pump: To use CNP

2. High-pressure pump: To use CNP

3. Reverse Osmosis Membrane: To use DOW, China

4. Pre-treatment device: To use PVC tank with manual valve

5. Conduit: To use PVC

6. Electric standard configuration: PLC automatically control

7. Electrical components: To use Zhengtai's and Schneider's products

8. Frame: To use stainless steel. 4 Reverse Osmosis Modules( RO)

RO system is key part for the water treatment system, which is widely used to make the pure water and drinking water. RO membrane removes many types of large molecules and ions from solutions by applying pressure to the solution when it is on one side of a selective membrane. The result is that the solute such as iron, Virus, bacteria and solids is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side.

5 Piping, Valves & Fittings

The pipe, valves and fittings (including tubing) ball valves, butterfly valves, piping used to the system is SS304. Reverse Osmosis Modules is equipped with sample valve for the convenience to check the product water.

6 Control devices

The whole automatic production line is achieved through the converter and PLC programmer and data collector such as the liquid lever sensor, flow sensor and etc. The whole production line is monitored by remote computer. When the water level of the product water tank is high, the system will stop automatically. When the water level of the product water tank is low, the system will run automatically. Advantages of RO systems:

Running stablely, high desalination and recovery rate.

Easy to operate and small maintenance workload

Compact structure and saves installation place.

Highly efficient and low energy consumption

No secondary pollution and low operation cost

Applications for RO plants:

• Homes and villas

• Hotels/hospitals

• Commercial complexes

• Kindney dialysis Unit

• Poultry farms

• Food and beverages industry

• Bottled water plants

• Cooling tower /boiler feed water