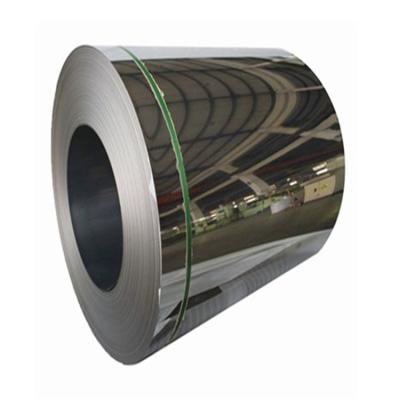

Top Quality No.4 Hairline SB 4 Finish Surface 430 Stainless Steel Coil/Roll For Refrigerator Kitchens

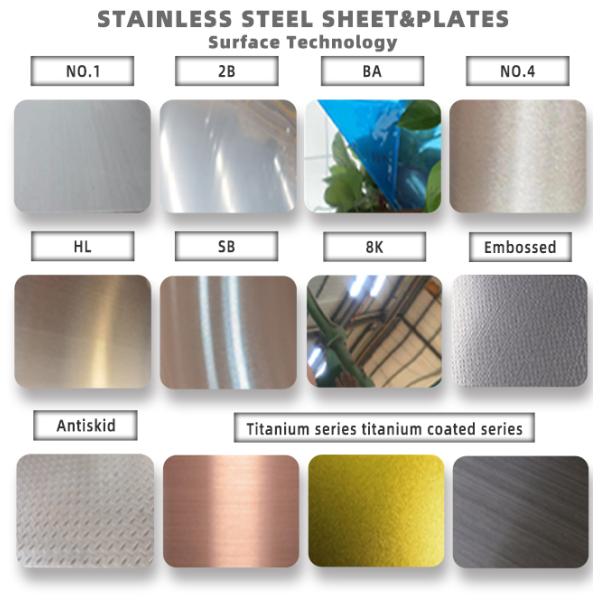

No. 4:A linearly textured finish that may be produced by either mechanical polishing or rolling . Average surface roughness ( Ra) may generally be up to 25 micro-inches . ......

HL/ Hairline:Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size.

SB/ Scrach Bright:Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size.

Hairline SB Stainless Steel Coils

| Product Name | ASTM /AISI / SUS No.4 Hairline SB 4 Finish Surface 430 Stainless Steel Coil/Roll |

| Grade | 201,202, 301,302,303,304,304L,316,316L,321,308,308L,309,309L,309S,309H,310,310S ,410,420, 430,2205,2507,409,904L etc |

| Specification | Thickness:cold rolled 0.1~3mm hot rolled 3mm~6mm per customized |

| Width:914mm;1000mm;1219mm;1250mm;1500mm;1524mm or per customized |

| Finish/Surface: NO.1,2B,BA,8K,No.4,HL,SB,Embossed,Checkered, etc... |

| Standard | ASTM A240/240M ; ASME SA-240/SA-240M; JIS G4305; DIN/BS/NF EN10028-7 ; ISO;GB/T 3280-2015 |

| Technology | Cold Rolled; Hot Rolled |

| Edge | Mill Edge; Cut Edge |

| Trade Term | EXW , FOB , CIF , CFR, DDU, etc . |

| Application | Dinner set, Kitchen ware, Owner frame of security door, Auto vent-pipe, Vacuum cup Clean bucket water sink and so on |

| Advantages | Factory Price; Top quality; First-rate service; We have many long-term customers to prove our reputation. |

| Chemical Composition |

| ASTM | JIS | DIN/BS/NF EN | GB/T | ISO | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr |

S20100

201 | SUS201 | X12CrMnNiN17-7-5

1.4372 | 12Cr17Mn6Ni5N

(1Cr17Mn6Ni5N) | X12CrMnNiN17-7-5 | 0.15 | 1 | 5.50-7.50 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

S20200

202 | SUS202 | X12CrMnNi18-9-5

1.4373 | 12Cr18Mn9Ni5N

(1Cr18Mn8Ni5N) | ----------- | 0.15 | 1 | 7.50-10.00 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

S30100

301 | SUS301 | X5CrNi17-7

1.4319 | 12Cr17Ni7

(1Cr17Ni7) | X5CrNi17-7 | 0.15 | 1 | 2 | 0.045 | 0.03 | 6.00-8.00 | 16.00-18.00 |

S30400

304 | SUS304 | X5CrNi18-10

1.4301 | 06Cr19Ni10

(0Cr18Ni9) | X5CrNi18-9 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

S30403

304L | SUS304L | X2CrNi19-11

1.4306 | 022Cr19Ni10

(00Cr19Ni10) | X2CrNi19-11 | 0.03 | 1 | 2 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

S30900

309 | SUH309 | X12CrNi23-13

1.4833 | 16Cr23Ni13

(2Cr23Ni13) | X12CrNi23-13 | 0.2 | 1 | 2 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

S30908

309S | SUS309S | X12CrNi23-13

1.4833 | 06Cr23Ni13

(0Cr23Ni13) | X12CrNi23-13 | 0.08 | 1 | 2 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

S31000

310 | SUH310 | X15CrNiSi25-21

1.4841 | 20Cr25Ni20

(2Cr25Ni20) | X8CrNi25-21 | 0.25 | 1 | 2 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

S31008

310S | SUS310S | X8CrNi25-21

1.4845 | 06Cr25Ni20

(0Cr25Ni20) | X8CrNi25-21 | 0.08 | 1 | 2 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

S31600

316 | SUS316 | X5CrNiMo17-12-2

1.4401 | 06Cr17Ni12Mo2

(0Cr17Ni12Mo2) | X5CrNiMo17-12-2 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

S31603

316L | SUS316L | X2CrNiMo17-12-2

1.4404 | 022Cr17Ni12Mo2

(00Cr17Ni14Mo2) | X2CrNiMo17-12-2 | 0.03 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

S31635

316Ti | SUS316Ti | X6CrNiMoTi17-12-2

1.4571 | 06Cr17Ni12Mo2Ti

(0Cr18Ni12Mo3Ti) | X6CrNiMoTi17-12-2 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

S32100

321 | SUS321 | X6CrNiTi18-10

1.4541 | 06Cr18Ni11Ti

(0Cr18Ni10Ti) | X6CrNiTi18-10 | 0.08 | 1 | 2 | 0.045 | 0.03 | 9.00-12.00 | 17.00-19.00 |

1.Good Quality and Complete Specifications

The cutting is flat and smooth,advanced technology reliable quality complete specifications. 2.Accurate Tolerance

Advanced machine production,exquisite workmanship,accurate thickness strict testing,each product is produced in strict accordance with the requirements.

3.Support Customization

There are many product styles, complete specifications,support customization.

4.Professional Packaging

Single box packaging.standard export sea-worthy packing and standard carton or according to customers demand for steel customized.

Certificates