- Material: Stainless steel 316 L, stainless steel 304, 304 L, 316, Monel, Hastelloy, and other materials can be custom produced.

- Filtration accuracy: 0.5 micron to 200 microns.

- Heat resistance: 800 °C.

- Standard thickness: 1.7 mm for 5 Layers; (3.5 mm for 6 Layers.)

- Standard size: 500 mm × 1000 mm, 600 mm × 1200 mm, 1000 mm × 1000 mm, 1200 mm × 1200 mm, 1500 mm x 1500 mm, other sizes can be made according to the customers’ requirement.

- Maximum size: 1500 mm × 1500 mm.

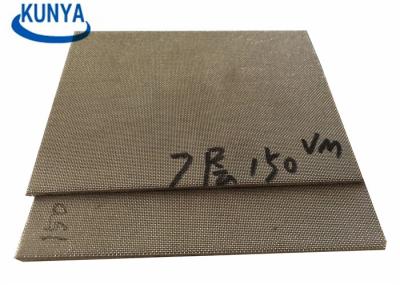

- 5 Layer Standard Sintered Wire Mesh Structure Show:

- 5 Layer standard sintered wire mesh technical data:

Noted: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm. And it has the higher anti-pressure ability

Noted: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm. And it has the higher anti-pressure ability

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Noted: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm. And it has the higher anti-pressure ability

Noted: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm. And it has the higher anti-pressure ability