UV LED Curing System 2500W 395nm Switching signal Dimming& Water cooling for High intensity curing&3D printer

2500W 395nm UV Curing System Product Specifications

| Models | LN-CP-1250 |

| Dominant Wavelength | 395nm |

| Recommend Radiation distance | 3-10mm |

| Control method | Water cooling |

| LENS | QUARTZ GLASS LENS |

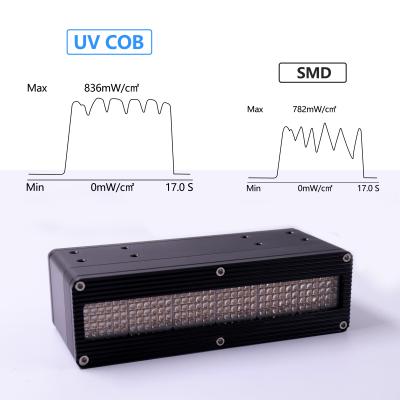

| CHIPS | High power SMD or COB |

Curing system Design Advantage:

1. Long lifespan

2. Low thermal resistance

3. High efficiency (45%-55%)

4. Inorganic encapsulation

5. High density and intensity

6. Screw-free assembly for high power curing use

7. Multi-wavelength (365nm/385nm/395nm/405nm/420nm) in one design

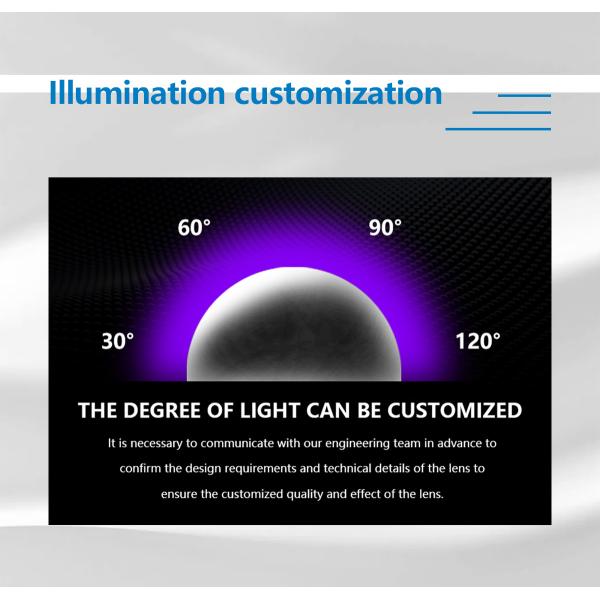

8. Optical optimization with special view angle in 30°, 60°, or 120°

LED Curing System Appilcation:

1,UV curing

2,LED growing market

3,Offset printer

4,3D printer

5,Exposure machines

6,Inkjet printer

7,High intensity curing Market like 3KW,7kW,15KW...

UVA System Product picture

IT HAS BEEN PROMOTED

UV-LED curing system technology has constant light intensity.excellent temperature control, portable and environmentally friendly features, relatively low procurement costs and virtually zero maintenance costs, and improves the quality and efficiency of the UV curing process.

THE DEGREE OF LIGHT CAN BE CUSTOMIZED

It is necessary to communicate with our engineering team in advance toconfirm the design requirements and technical details of thelens to ensure the customized quality and effect of the lens.

Photoconversion in water-cooled solidification systems

UV light is used to trigger the curing process in water-cooled curing systems. The UV light is generated by a UV lamp or LED light source, which emits UV light. The UV light then travels through a window of quartz or fused silica into the curing chamber. A photoinitiator in the UV-curable coating or adhesive captures the UV light, which triggers a chemical reaction to begin the curing process. The curing process releases heat, which can increase the temperature in the curing chamber. To prevent overheating and damage to the curing system, water runs through the curing chamber to cool down the heat released during the curing process. The water temperature is adjusted to maintain a stable curing temperature, which can help ensure consistent and effective curing.

In summary, water-cooled curing systems use UV light to trigger the curing process, which releases heat that is cooled by water to maintain a stable curing temperature. This process allows for efficient and effective curing while avoiding the risk of overheating and damage to the curing system.

3D/Inkjet Printer UV LED Curing System FAQ

Q1: Can you provide OEM,ODM service?

A1: Yes, we can provide OEM and ODM services.

Q2: Are the pictures all real photos?

A2: Yes, all the pictures of our products on this page are 100% real photos.

Q3: How can I get a quote from you?

A3: To get a quote from us, please leave us messages about your requirements, including products and quantity. Our professional team will reply to you very soon (mostly within a few hours).

Q4: Is there any discount for large order?

A4: Yes, if you need a large order or you want customized products, we can offer wholesale prices.

Q5: Do you support drop shipping and how much is the shippping cost?

A5: Yes, we support drop shipping. You should leave the receiver’s information when you place the order, then we will send the goods according to the address you have left. The shipping cost is based on your order’s volume and weight, and it can be calculated.

Q6: How to make an order?

A6: If you want to make an order, please feel free to send us an inquiry email or contact us by trademanager online. We will reply to you within 24 hours (working day).

Q7: What payment methods are available?

A7:We accept T/T, PayPal, Western Union and Secure Payment.

Q8: What about the delivery time?

A8: It depends on the order quantity. In general, delivery time is about 3-75working days. For samples, the delivery could be as fast as same day.