Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

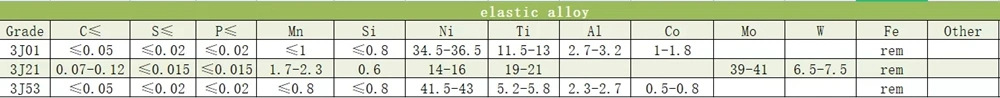

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53

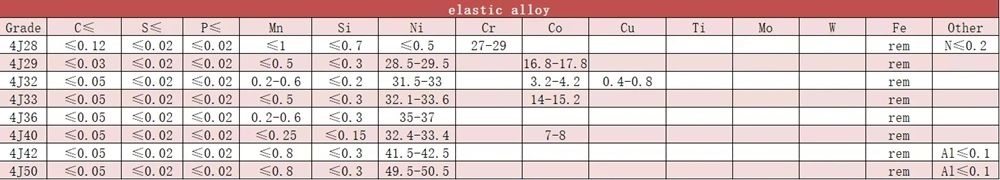

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53 Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50