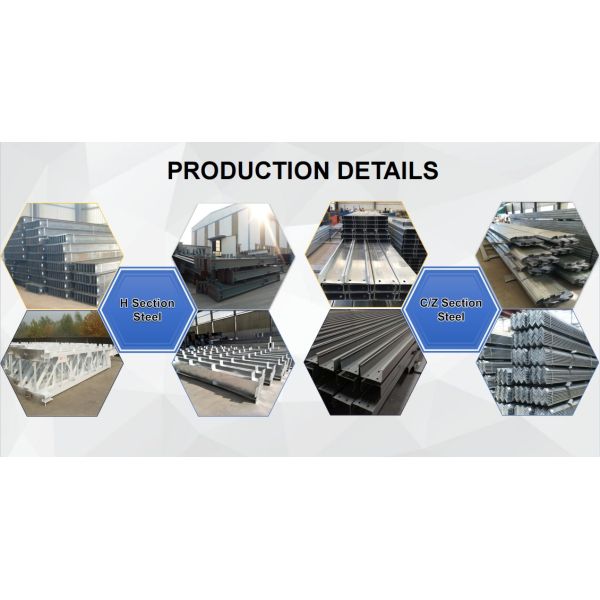

| Steel Structure Fame | Light weight steel structure |

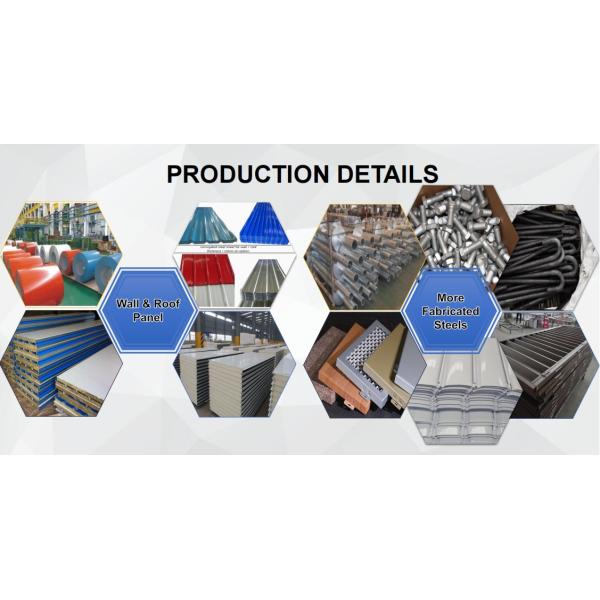

| Roof & Wall Cladding system | Steel sheet; Sandwich panel |

| Sandwich panel thickness | 50-200mm |

| Door Material | Sandwich panel door; Security door |

| Window Material | Plastic steel window; Aluminum allow edge window |

High Strength But Light Weight

Steel has high strength and high modulus of elasticity. Compared with concrete and wood, the steel structure has a lighter weight. So it is easier to transport and install. And it is obviously better suitable for large spans, high rise, and heavy loads structure.

More toughness, More plasticity, Material Uniform & More reliable structure

Steel material is better to undertake impact and dynamic loads with good seismic performance. Its internal structure is uniform, close to an isotropic homogeneous body. The actual working performance conforms to the calculation theory. Therefore, the reliability of the steel structure is high.

The steel structure production should be processed strictly as the requirements. During the production, anti-corrosion paint to the components is important. Today, we will introduce that which parts do not need to be painted and which are prohibited painted.

Parts that do not need to be painted:

(1) Anchor bolts and bottom plate;

(2) The part that is close to or buried in concrete;

(3) The inner surface of the seal;

(4) Surfaces that are tightly combined by assembling;

(5) Stainless steel surface;

(6) Designed parts that do not need to be painted.

Parts prohibited from painting:

(1) High-strength bolt friction joint surface;

(2) Machining surface required for mechanical installation;

(3) The area of 50-100mm on both sides of the adjacent parts to be welded on site;

(4) The nameplate and logo of the equipment;

(5) Designed areas where painting is prohibited.

For the parts that are forbidden to be painted, measures should be taken to shield them.

Steel Frame Installation

In the installation process of the large-span space steel structure, if there is a problem directly in the construction part, the slipping construction method is an effective solution.

There are generally two slip methods: structural slip method and supported slip method.

Structural slip method: The basic idea is to install all (or parts) of the structure on a site with assembly conditions, and then use the slip system to move the structure to the right position.

Supported slip method: a support frame is set on the basis of the structural design to provide a support and operation platform for the on-site installation of the structure. After the structural part is installed, the support frame is separated from the completed structure. This creates conditions for the on-site installation of adjacent structures until the structure is completely installed.