| Details | 1. Size (Length* Width* Eave height, roof slope) : MOQ as 200sqm |

| 2. Type: Single slope, Double slope, Multi slope Single span, Double span, Multi span Single floor, Double floors | |

| 3. Base: Cement and Steel foundation bolts | |

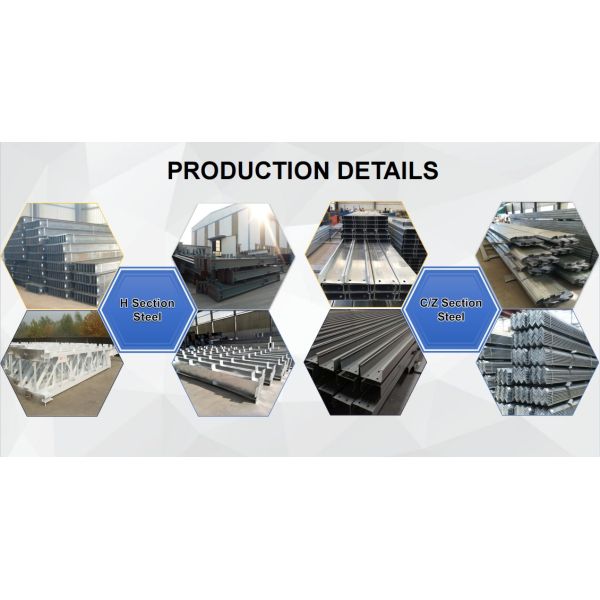

| 4. Column & Beam: Q345(S355JR) or Q235(S235JR) steel, all bolts connection! Straight cross-section or Variable cross-section! | |

| 5. Bracing: X-type or V-type or other type bracing made from angle, round pipe, etc | |

| 6. C or Z purlin: Size from C120~C320, Z100~Z200 | |

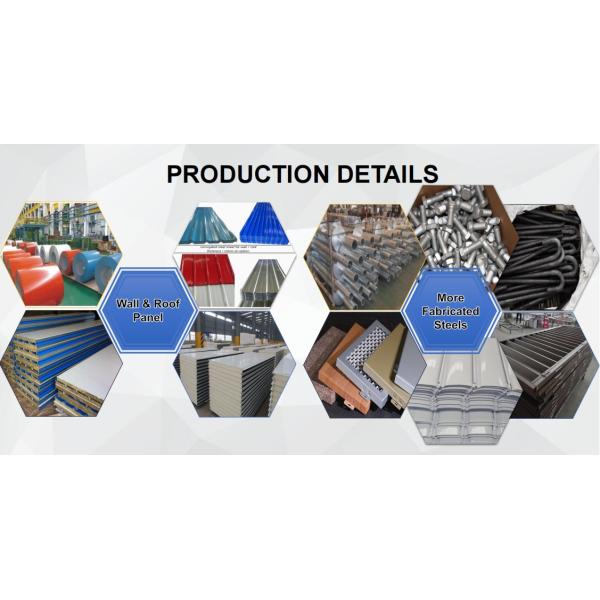

| 7. Roof and wall panel: Single steel sheet: thickness 0.326~0.8mm Sandwich panel: thickness 50mm~100mm | |

| 8. Accessories: Semi-transparent skylight belts, Ventilators, down pipe, galvanized gutter, etc | |

| 9. Surface treatment of steel: 2 layer epoxy zinc rich primer and 2 layer antirust paint |

Three-steps to control steel structure projects quality

First step, Materials

Strict control of materials is the first step.

Before the production and process of steel structure components, we should check whether the steel type, specification and quality of the steel meet the designed requirements and standards, and use it after confirming that it is qualified.

High-strength bolts, ordinary bolts, and qualified welding rods, welding wires and fluxes are selected according to the steel grade, all are should be paid attention.

Step two, Installation

The installation method of steel structure projects is very important.

After the anchor bolts are leveled, connect them in accordance with regulations. First install a column beam, then the support is installed to form a system. After that one span is finished, the next span is started. This installation is safe and without any hidden dangers. The positioning of the steel column must be accurate. The elevation of the top of the column must be consistent and on the same straight line. The correct connection method and reasonable design of the connection form play an important role in the installation of steel structures.

Step three, Technology

No matter how good the material is and how best the method is, the construction personnel must have rich experience in construction technology. The technology and qualifications of welders and crane workers must be checked and guaranteed. At the same time, the project department is required to establish a quality assurance system and technical personnel shall be certified.

Preparation Of Steel Structure Construction

⑴Technical Preparation:Develop the installation technical plan.

The single-layer steel structure project should adopt the separate installation method. The roof system should adopt the comprehensive installation method. Multi-layer steel structure project generally adopts comprehensive installation method.

⑵Construction equipments and materials Preparation

Including hoisting machinery, various auxiliary construction equipment, steel structure components, various welding materials and fasteners, etc.

⑶ Column foundation inspection

Column foundation leveling and elevation control; Review the axis and spring up the alignment line;Check the axis position, size and quality of the anchor bolt.

⑷ Component cleaning

clean up the steel pillars and other lifting steel components in advance; Nnumber them and mark the installation line.