Five commonly used assembly methods for steel structural components:

1. Ground sampling method

Assembly method: Use a ratio of 1:1 to put the actual components on the assembly platform. Then, according to the position of the parts on the actual sample, they are assembled into components.

Use range:

Small batch structure assembly, such as trusses and frames

2, Copy and assembly method

Assembly method: First assemble into a single-sided (single piece) structure by ground pattern method. And the spot welded is necessary. Then turn over as a duplicate tire mold, assemble another single-sided structure on it, and assemble twice.

Use range:

Truss structure with symmetrical cross sections

3, Stand up method

Assembly method: Choose top-down or bottom-up assembly according to the characteristics of the component and the stable position of the parts.

Use range

Used to configure a stable, low-height structure or large diameter cylinder

4, Lying down method

Assembly method: assembly on the position where the component is placed.

Use range:

Used for slender members with small cross-section but large length

5. Fetal membrane assembly method

Assembly method: the assembly of the parts of the component with the tire mold positioned at its assembly position.

Use range:

Used to manufacture products with large batches of components and high precision

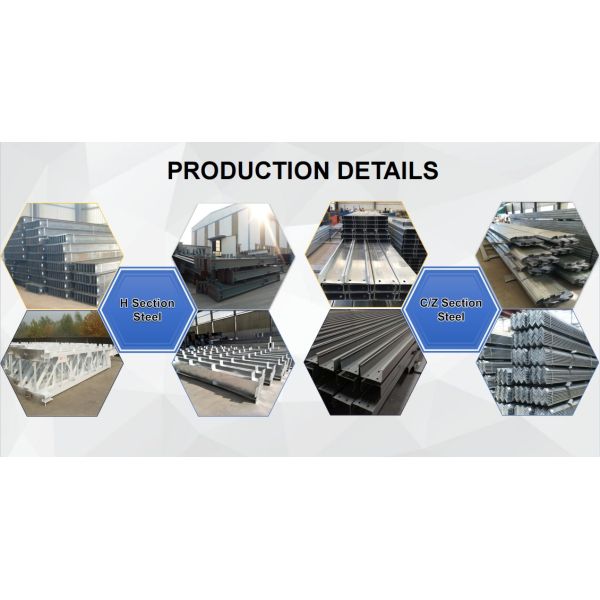

| Main components | Base | Cement and steel foundation bolts |

| Main frame | H-section steel | |

| Material | Q235B, Q345B or others as buyers' requests. | |

| Purlin | C / Z Steel: Size from C120~C320, Z100~Z20 | |

| Bracing | X-type or other type bracing made from angle, round pipe | |

| Bolt | Plain bolt and High-strength bolt | |

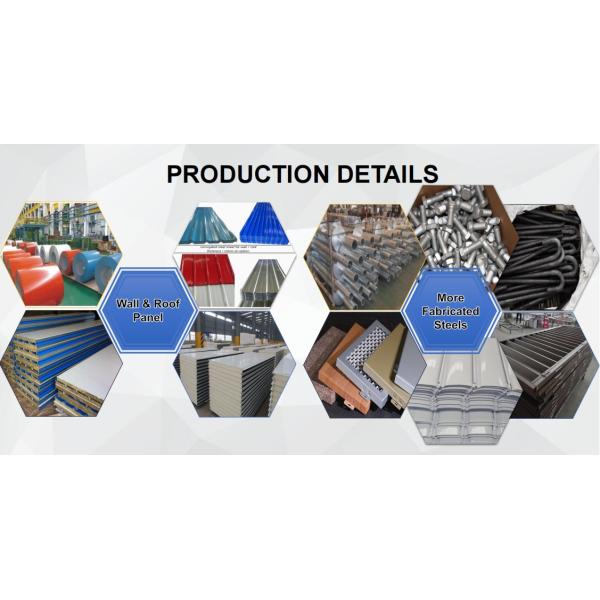

| Roof & wall | Sandwich panel or Single steel sheet | |

| Door | Sliding door / Rolling door / Securing door | |

| Window | Aluminium alloy frame | |

| Surface | Total four layers of Anti-rust Painting or Galvanized |

Steel Frame Installation

---Steel column installation

The steel column should be lifted by one-point straight lifting lashing method. When in place, align the anchor bolts and slowly drop. After alignment, screw on the nut to temporarily fix the column, correct its plane position and verticality. After the correction, finally screw the nut and use the backing plate is welded firmly to the column bottom plate. Then the column bottom is grouted and fixed.

---Steel crane beam installation

The crane beam is lashed at two points, and when hoisting, the aerial posture of the components during the hoisting process is controlled by a sliding rope to facilitate alignment and avoid collisions. After being temporarily fixed in place, the verticality, elevation, and vertical and horizontal axis positions of the crane beam should be corrected.

---Roof system installation

The roof truss installation should be carried out after the columns are calibrated and fixed. The roof system can be hoisted after the expansion assembly assembly, and the expansion assembly assembly unit should become a spatial structure with certain rigidity. The installation of purlins and other components should be carried out after the roof truss is adjusted and positioned.