View of our factory:

Prouduction equipment showing:

Welding and cutting machine

The H section steel plate should be checked again by our factory and shall be applied under the condition of up to design and specified requirements after checking. Steel plate cutting should be aimed at quality guarantee and material saving. For each process like plate cutting,H type assembly, components assembly and pre-assembly should be carried out by profession setting-out worker precisely on processing surface and assembly sample plates.To guarantee the accuracy of the components’geometrical dimension,tolerance of form and position, angle and contact surface,inspection is necessary by QC teams after setting out.In order to ensure the cutting quality,the surface of the ultra-thick plate is subjected to the surface carburizing hardness test before cutting.The laser cutting equipment is preferred for cutting.

H section steel assembly

The assembly process is set up on the imported H section production line.4 hydraulic positioning system press firmly against between the upper/lower flange and web plates in position. The adjust the parallelism of the flange plates and perpendicularity between flange and web plates and get them fixed after.

Automatic welding

The H section steel members will be hoisted into the gantry-type submerged arc automatic welding machine for welding.The welding process should be carried out in accordance with specified welding sequence and regulation parameters.Preheating, which uses the electrical heaters, is necessary for the ultra-thick plates of components.The set temperature shall be determined based on the specified one.Please see factory welding process documents for detail.

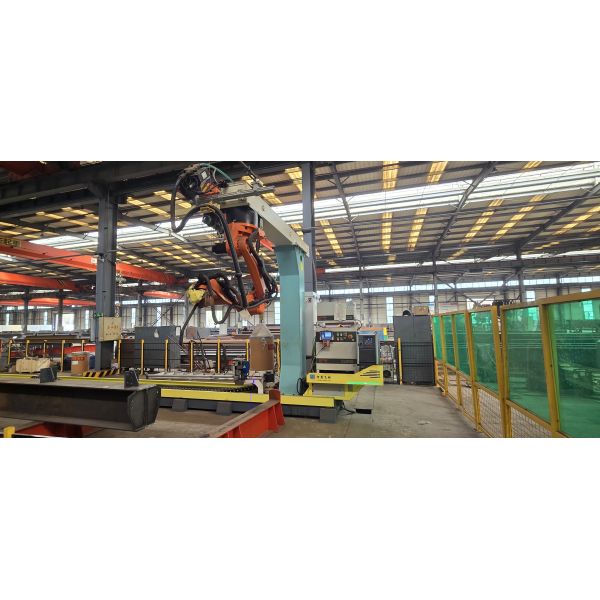

Welding robot

Stabilize and improve welding quality, and be able to reflect welding quality in numerical form; Improve labor productivity;Improve the labor intensity of workers;Reduced the requirements for workers' operational skills.

Photos taken after robot welding

Equipped with various testing equipment in the laboratory

Steel hardness tester

Testing result:

Temperature debugging device

Impact test

High strength bolt torque tester

Spectrometer chemical composition content testing

.

GROUP DEVELOPMENT HISTORY:

Sailing forward: Embark on a journey of infinite promise

(2002) Qingdao Yidongxiang Steel Structure Co., Ltd. opened a new milestone in the history of Yidongxiang's development.

(2002) The purchase of the first waveform pressure tile machine marks the company is entering into the era of steel structure material processing.

(2002)We have undertaken the glass curtain wall project for the office building of the Urban Construction Commission, covering an area of 12,325 square meters.

(2005) We have undertaken the glass curtain wall project of Huaxia Mall, with a project area of 13,500 square meters.

(2006) We have undertaken the glass curtain wall project for the highway section, covering an area of 8,000 square meters, and the production and installation of plastic steel doors and windows, covering an area of approximately 10,000 square meters..

(2007) The glass curtain wall project of the Industry and Commerce Bureau has been performed successfully by our group,with a project area of 60,000 square meters.

Exploration: Once the direction is chosen, brave every storm without hesitation

(2009) We have undertaken Steel Structure Workshop Construction Engineering and Office Building Decoration Engineering of Qingdao Takma Technology Co., Ltd., the project area is more than 6,000 square meters.

(2009) We have undertaken the curtain wall project of the Waterfront Haoting Sales Office and the production and installation engineering of plastic steel doors and windows in the community The area is more than 30,000 square meters.

(2010) The steel structure workshop project and office building decoration project of Qingdao Anyando Carbon Co., Ltd. has been performed successfully by our group.

(2011) Propose the operation standard of innovation, specialization, standardization, systematization, process, data, informatization and transparency.

(2012) We have undertaken the manufacture and installation project of insulation aluminum alloy doors and windows of Pingdu People's Hospital, and also the decoration work for the inpatient and outpatient buildings.

(2013) The production and installation project of steel structure curtain wall corridor of Pingdu People's Hospital has been performed successfully by our group.

(2014) Pingdu Xianhe Ecological Forest Farm Project (the third bid section) of Dazeshan Forest Farm , with a project area of 478,699 square meters which has been performed successfully by our group.

Growth: Let mountains and rivers bear witness, and time inscribe our legacy

(2015) The membrane structure carport project of Pingdu Vocational Education Center, with a project area of 19,878 square meters has been performed successfully by our group.

(2016) We have undertaken the contracting project of South Korea's wholly -owned enterprise of Qingdao Yongpu Industrial Park, with a project area of 17,510.78 sqm.

(2017) The thermal engineering project of Pingdu City with a project area is 26,6708 square meters has been performed successfully by our group.

(2018)We have undertaken the Apartment Project of Laixi Jiangshan Industrial New City , with a project area of 22,088.37 square meters.

(2018) The municipal engineering project of the spring Community project in Fengtai Street, Pingdu City, with a construction area of 87,239.24 square meters has been performed successfully by our group.

(2018) The project of Pingdu City's new and old kinetic energy conversion industrial park has been performed successfully by our group, the project area is 34,880 square meters.

(2018) The food grade probiotics production project in Pingdu city with total area of 5,761.45 square meters has been performed successfully by our group.

(2018) We have undertaken the first phase of Pingdu Airport Economic North District construction project, with a project area of 104,256 square meters.

Strength: With aspirations like a radiant arc, forge ahead with unyielding strength

(2019) We have undertaken the PPP project of Qingdao Pingdu Central Hospital (Phase I), with a project area of 58,000 square meters.

(2019) We have undertaken the decoration project of the first and third floors of office area of Building B, Shangpin Plaza,Pingdu city, with a project area of 2,600 square meters.

(2020) The first phase of the construction project of Pingdu Airport Economic North Zone, with a project area of 104,256 square meters has been performed successfully by our group.

(2020) We have undertaken the Shanxi Engineering Steel Structure Report Hall project, with a project area of 5,004 square meters.

(2020) We have undertaken the first phase of Pingdu Guofu Elderly Care Project, with a project area of 26,266.77 square meters.

(2020) We have undertaken the relocation and new construction project of Shandong Vocational College of Culture and Industry, with a project area of 67,233.46 square meters.

(2020) The first phase outdoor supporting project of Shandong Cultural Industry Vocational College, with a project area of 63,649.74 square meters has been performed successfully by our group.

(2020) We have undertaken the outdoor cable engineering project for the relocation and new construction of Shandong Cultural Industry Vocational College, with a project area of 40,000 square meters.

(2020) We have undertaken the Laixi Jiangshan Industrial New City Headquarters Port (Hotel) project, with a project area of 30,791.92 square meters.

(2020) The second phase of Pingdu Guofu Elderly Care Project, with a project area of 57,490.28 square meters has been performed successfully by our group.

Breakthrough: Advance with resolve and aim far beyond the horizon

(2021) The double Innovation Center project of Shandong Vocational College of Cultural Industry has been performed successfully by our group, with a project area of 9,810 square meters.

(2021) We have undertaken the outdoor supporting project of Shandong Cultural Industry Vocational College Phase II, with a project area of 19,830 square meters. square meter.

(2021) The glass curtain wall project for the standardized factory building of Huizhong Finance in Bincheng District, with a project area of 62,583.01 square meters has been performed successfully by our group.

(2021) We have undertaken the urban heating supporting project, including the heating pipeline, network supporting projects of Hisense Fengtai Shijia and other residential areas, with a project area of 155,000 square meters.

(2021) We have undertaken the high-temperature water pipe network project in the Libanzhuang area and Zhengzhou Road (Tianjin Road to Nanjing Road), with a project area of 58,009 square meters.

(2022) The decoration and renovation project of the comprehensive building of Qingdao New Oriental Bilingual School, with a project area of 128,680 square meters has been performed successfully by our group.

(2022) We have undertaken the smart factory project of Qingdao Huadi Food Ingredients Co., Ltd., with a project area of 10,400 square meters.

(2022) We have undertaken the infrastructure supporting construction project of Xinhe town Eco-Chemical Industrial Park with an area of 72,052 square meters.

(2022)We have undertaken the agricultural machinery parking project of Dahuangbu Community, Mingcun Town, Pingdu City, with a project area of 6,780 square meters.

(2023) The 8 # international student apartment building project of Shandong Cultural Industry Vocational College, with a project area of 10,330.73 square meters has been performed successfully by our group.

(2023) We have undertaken the renovation project of old residential areas in Laoshan District (Jinjialing Street) (design and construction general contracting) for Section 11, with a project area of 15,130 square meters.

(2024) We have undertaken the infrastructure construction project of Baishahe Street in Pingdu City, with a project area of 15,558 square meters.

(2024) We have undertaken the infrastructure improvement project for poverty alleviation key villages in Yunshan Town, Pingdu City, with a project area of 285,680 square meters.

Future: Together, toward the light of a brighter tomorrow

2025 – Embracing the future

Our Service

I. We would offer you the proposed design plan and the most valuable quotation based on the parameter of the following information.

1. Building Dimension: Length*width*height, eave height, roof type etc.

2. Doors and windows: Dimension, quantity, position to put them if you have your own requirements.

3. Local climate: Wind speed, snow load, earthquake etc.

4. Insulation material for roof and wall: Sandwich panel or single metal sheet.

5. Crane if have: Do you need crane beam inside the steel structure? And its capacity.

6. If have other requirements, such as fire proofing, isolated roof ,roof ventilation and daylighting etc, please kindly inform us.

II. In accordance with your requirement, our experienced engineers would provide the best program.

III. We would give the best service to our client, including design, manufacturing,installation and after-sale service etc.

We can provide the service of installation, supervision, and training by extra. We will dispatch our engineers team to your country to guide the assemble work, and we will provide the detailed professional installation drawings and guide installation service team keep 24-hour online service ,they will help you to install your steel structure building .

IV. QC processing:

1. Every one week meeting for Quality Audit to solve the weakness during processing and procedures

2. Every two weeks meeting for employee training.

3. Producing as to the International Steel Structure Standard with ISO 9001 Quality Control System

4. Each project, every 1 months, connect with clients for feedback and complaints, then improve the quality control actions.

5. Quality inspection report for every process during production. Ensure 100% good quality products.

FAQ

I. What kind of Industry Steel Workshop do you need?

There are very experienced, expertised engineers in our company who can design whatever shape of buildings as your request. Your building is a major investment and you take it seriously. So do we!

II:Are you manufacturer or trade company?

We are professional manufacturer of steel structure building.

III:Do you offer guiding installation on site overseas for warehouse building?

Yes, we can provide the service of installation, supervision, and training by extra. We will dispatch our engineers team to your country to guide the assemble work, and we will provide the detailed professional installation drawings and guide installation service team keep 24-hour online service ,they will help you to install your steel structure building .

IV. What's the quality assurance you provided and how do you control quality?

We have professional QC team monitoring the quality at all stages of the manufacturing process - raw materials, in-process materials, validated or tested materials, finished Goods and packing the Goods, we also accept the third party International inspection agencies to inspection the quality such as SGS,BV etc.

V. Could you offer designing service?

We have complete engineering team and we are using the state of the art designing and manufacturing software, Tekla, Advance Steel,Auto CAD, PKPM, MTS, 3D3S, Search etc. We are capable of designing and offering your economical solution to your needs if there is any inquiry. Please do not hesitate to contact which will be at your disposal at any time. Please note preliminary costing and design will be done at no extra cost.

IV:Is there any warranty available on the steel structure buildings?

The steel structure buildings have limited warranty. Usually,steel structure houses with long use lifespan which can reach 50 to 100 years which depending on material quality, design standards, construction quality, and subsequent maintenance.