1.

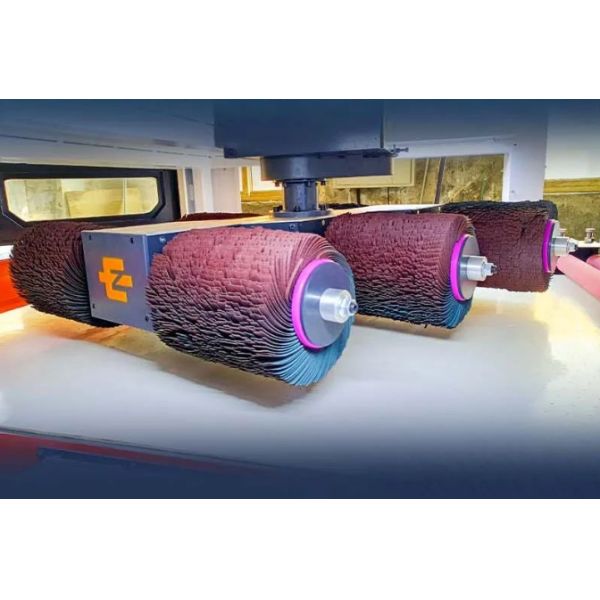

More convenient setting. Integrated function setting+LED touch screen.2. Lower material cost. Universal sand belt wheel can last 2~3 months; multiple sand belt wheels (80~120 molybdenum) are available.

3. Safe. Automatic braking of abrasive belt during alarm and power failure, effective limit protection at all positions, etc.

4. Clean. Dust and debris can be connected to the dust removal system.

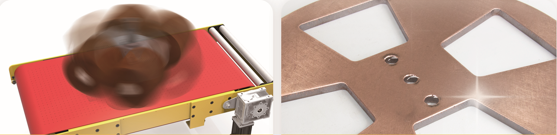

5. Multiple choices. For magnetic-capable material processing, magnetic adsorption function is standard configuration, greatly reduce device power consumption; For materials that cannot be magnetically attracted, vacuum negative pressure workstation can be selected for adsorption processing.

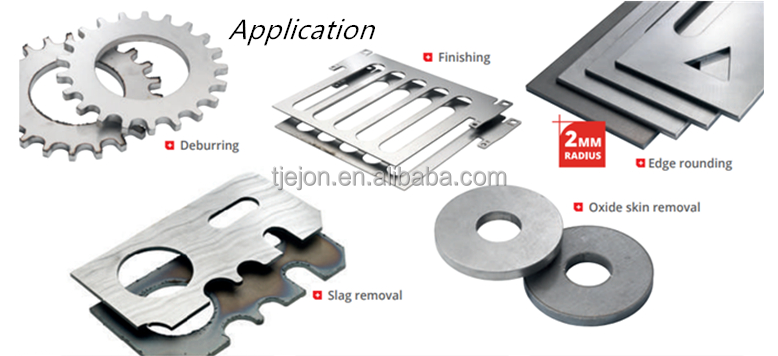

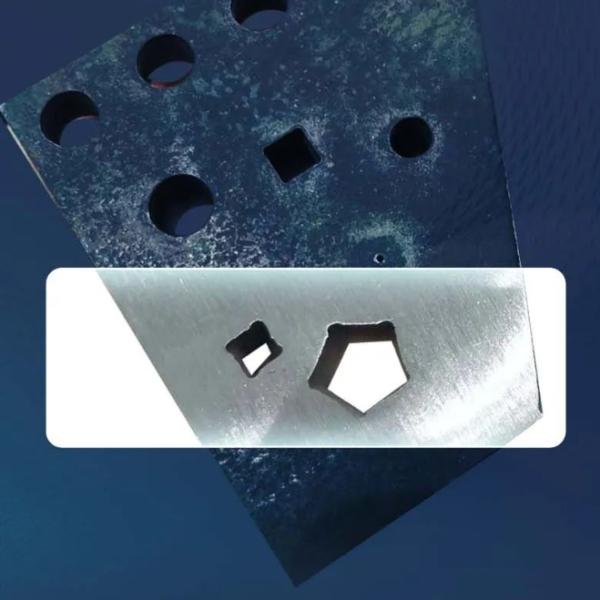

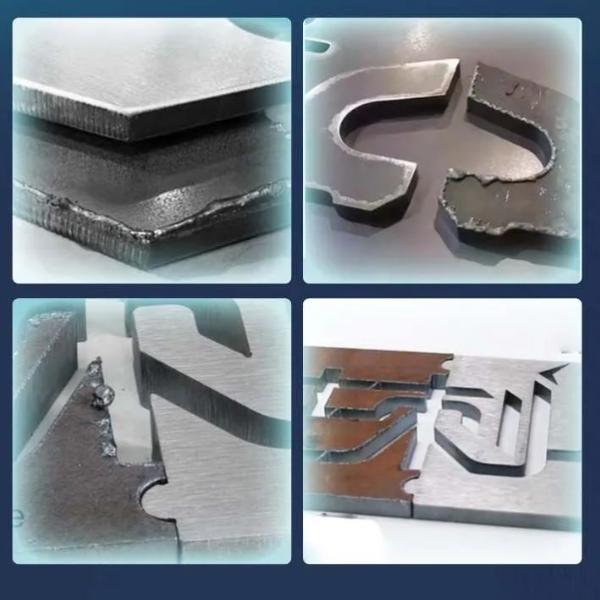

6. Parameters visual adjustment. The grinding and stroke parameters can be freely adjusted visually, can only grind the contour and sharp edge of the workpiece without damaging the surface.

7. Two grinding procedures. The burr can be removed and the oxide layer can be kept, or the oxide layer can be completely removed.

8. Easy hoisting. The whole structure is welded with thickened profiles to ensure stable operation and facilitate lifting and forklift operation.

9. More powerful. Two-station drive motors are all 18.5 kW in power.

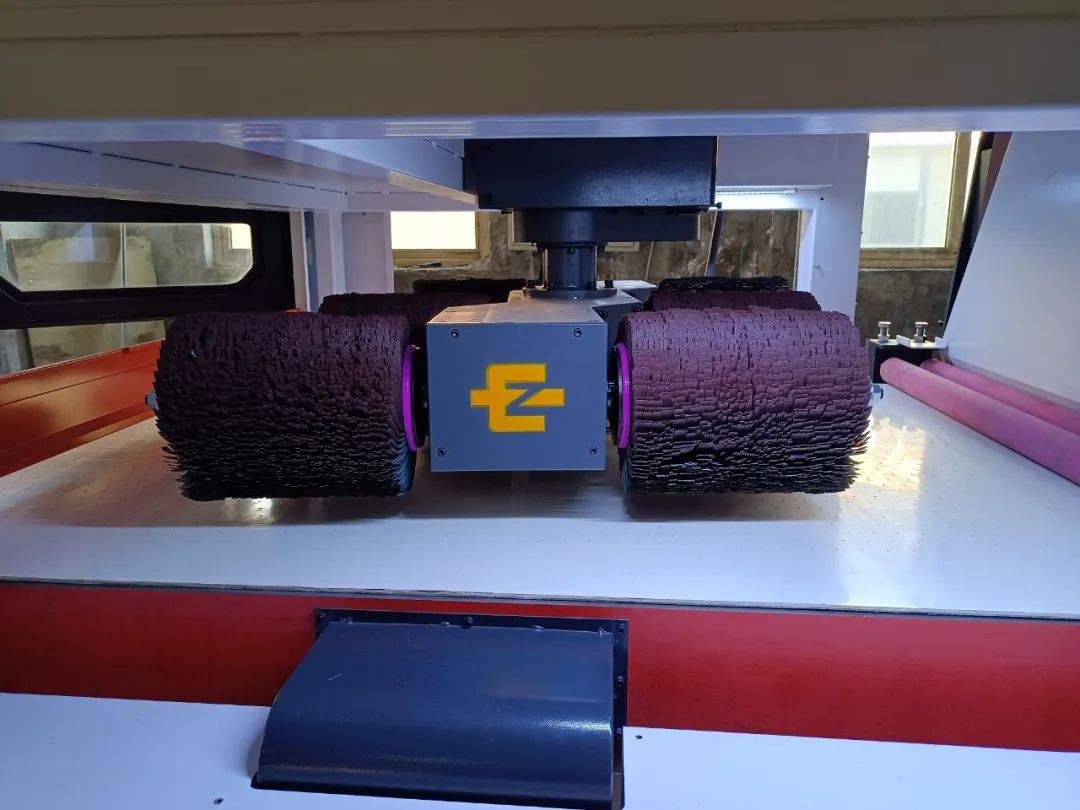

10. Independent height adjustment. The chamfer part adopts double frequency conversion control to adjust the height independently.