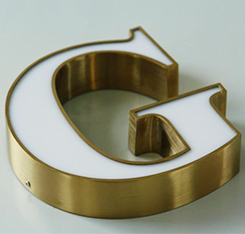

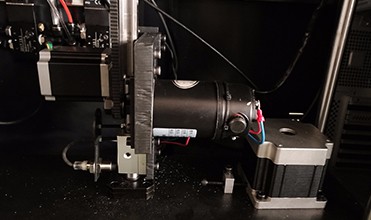

Alloy milling cutter slotting system for Aluminum plate and Aluminum profiles.

The feeding support adopts an integral casting structure,which effectively avoids the deformation generated during the feeding and ensures the stability of feeding.

SPECIFICATIONS | ||||||

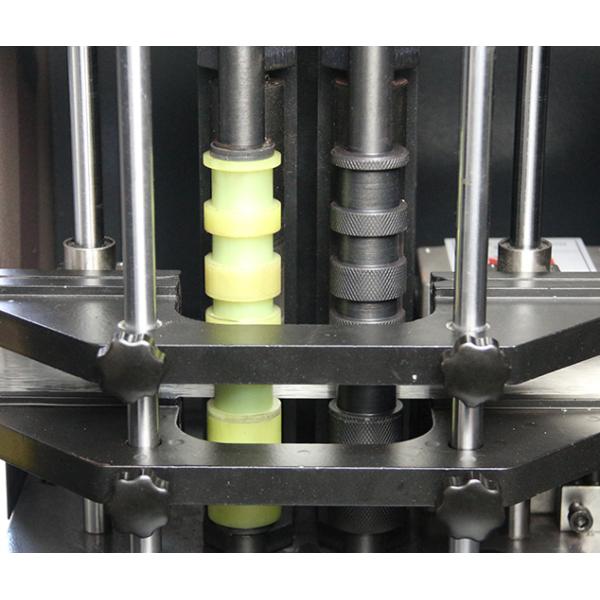

Feeding System | Roller circulation feeding system | |||||

Slotting System | Alloy milling cutter slotting system | |||||

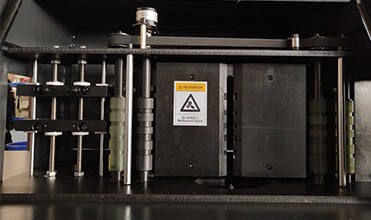

Bending System | Double bends bending system | |||||

Suitable Material | Flat Aluminum , Aluminium profile,Trim cap aluminum, Customized for different Materials | |||||

Material Height | 20~130mm | |||||

Material Thickness | 0.4~1.2mm | |||||

Control System | 4 axis control system | |||||

Min. Bending Angle | R6 | |||||

File Format | Dxf.Plt. | |||||

Power | AC220V,50Hz,2.0Kw | |||||

Total Weight | 200KG | |||||

Alloy milling cutter slotting system for Aluminum plate and Aluminum profiles.

The feeding support adopts an integral casting structure,which effectively avoids the deformation generated during the feeding and ensures the stability of feeding.

To use the device, you need to install the control card in your computer and then connect to the bending machine and install the software.Computer configuration : XP system or window7 32-bit system, and requires a PCI card slot to install the control card.

The use of equipment should be equipped with air compressor, we suggest that the selection of more than 4kw, the gas flow is 0.6m³/Min.

The software of bending machine is self-developed. Import file format supports .Dxf.Plt .AI We recommend using Coredraw or adobe illustrator to complete the file after the export file to.Dxf.Plt.Ai format. Then open the operating software, select the document.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.