Exchanger Type

-

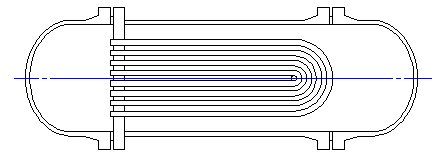

U-Tube has only one tubesheet. The tubes are bent in the form of a "U." The bundle can removed for maintenance, but the inside of the tube is harder to clean because of the bend.

-

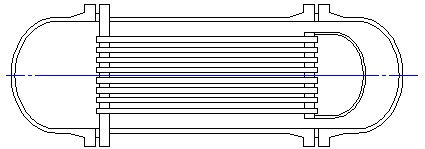

Fixed has two tubesheets that are fixed at each end of the exchanger and are connected to each other by straight tubes. Both the tubesheets are stationary, so differential thermal expansion can develop between the shell and the tubes. An expansion joint is sometimes required to absorb the thermal growth. You must select a fixed type of tubesheet exchanger to perform finite element analysis (YUHONG) on expansion joints.

-

Floating has one tubesheet that is fixed (stationary) and one that is free to move. Because one tubesheet floats, any differential thermal expansion between the shell and tubes is absorbed. This category of exchangers is the most versatile and also the costliest. Tubes can also be cleaned easily compared to U-tube exchangers.

| Carbon & Low Temperature | Chromiun | Stainless & Duplex | Copper& Bronze | Titanium | Ni-Alloy | |

| A105 /A105N | A182-F1 | A182-F304 | A182-F347H | SB151-C70600 | SB381-GR.1 | B564-NO2200 |

| A516-GR.70 | A182-F11 | A182-F304L | A182-F904L | SB151-C71500 | SB381-GR.3 | B564-NO6022 |

| A350-LF2 | A182-F12 | A182-F304H | A182-F44 | SB151-C71520 | SB381-GR.5 | B564-N10276 |

|

| A182-F22 | A182-F304N | A182-F51 | C44300 | SB381-GR.7 | B564-NO4400 |

|

| A182-F5 | A182-F309S | A182-F53 | C68700 | SB381-GR.12 | B564-NO6600 |

|

| A182-F9 | A182-F310S | A182-F55 | C71640 |

| B564-NO6601 |

|

| A182-F91 | A182-F310H | A182-F60 |

|

| B564-NO6625 |

|

|

| A182-F316 |

|

|

| B564-NO8800 |

|

|

| A182-F316L |

|

|

| B564-NO8810 |

|

|

| A182-F316Ti |

|

|

| B564-NO8811 |

|

|

| A182-F316H |

|

|

| B564-NO8825 |

|

|

| A182-F317L |

|

|

| B564-N10665 |

|

|

| A182-F321 |

|

|

| B564-N10675 |

|

|

| A182-F321H |

|

|

| B160-NO2201 |

|

|

| A182-F347 |

|

|

| B462-NO8020 |

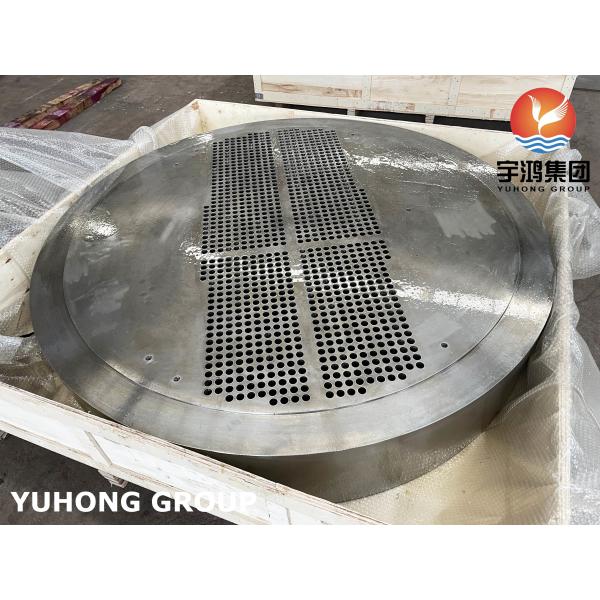

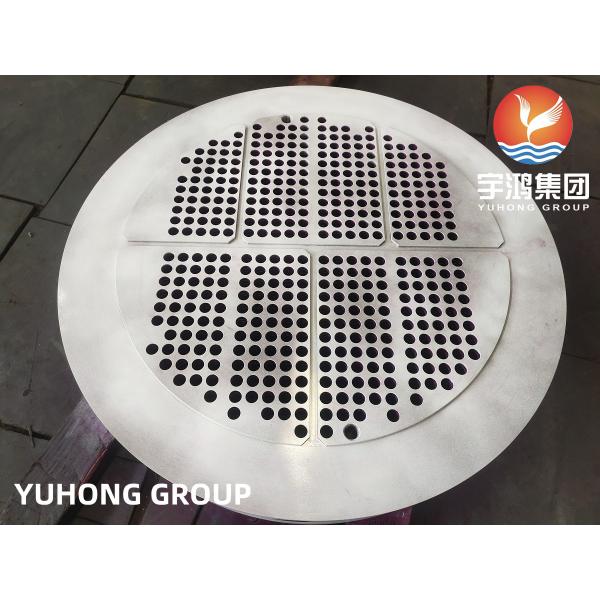

Tube sheet Available Raw material

| Type of materials | Technical requirements |

| Duplex Stainless Steel | ASTM/ASME SA182 F44, F45, F51, F53, F55, F60, F61 |

| Stainless Steel | ASTM/ASME SA182 F304,304L,F316,316L, F310, F317L, F321, F347 |

| Carbon Steel | ASTM/ASME A105, A350 LF1, LF2, A266, A694, A765 Gr.2 |

| Alloy Steel | ASTM/ASME SA182 F1, F5, F9, F11, F12, F22, F51, A350-LF3 |

| Non Ferrous |

|

| Titanium | ASTM/ASME SB381, Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 |

| Copper Nickel | ASTM/ASME SB151, UNS 70600(Cu-Ni 90/10), 71500(Cu-Ni 70/30) |

| Brass, Al-brass | ASTM/ASME SB152 UNS C10100, C10200,C10300,C10800,C12200 |

| Nickel Alloys | ASTM/ASME SB169,SB171, SB564, UNS 2200, UNS 4400, UNS 8825 |

| Alloy 20 | ASTM/ASME SB472 UNS 8020 |

| Hastelloy | ASTM/ASME SB564, UNS10276 ( C 276 ) |

| Claded materials | ASTM/ASME SB898, SB263, SB264 or closer |

| Titanium- Steel, Nickel-Steel,Titanium- Copper, |

Application

-

Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc