| Details | 1. Size (Length* Width* Eave height, roof slope) : MOQ as 200sqm |

| 2. Type: Single slope, Double slope, Multi slope Single span, Double span, Multi span Single floor, Double floors | |

| 3. Base: Cement and Steel foundation bolts | |

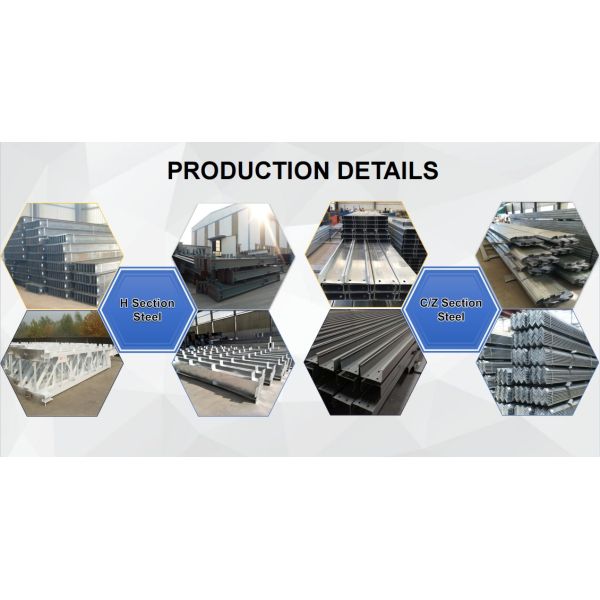

| 4. Column & Beam: Q345(S355JR) or Q235(S235JR) steel, all bolts connection! Straight cross-section or Variable cross-section! | |

| 5. Bracing: X-type or V-type or other type bracing made from angle, round pipe, etc | |

| 6. C or Z purlin: Size from C120~C320, Z100~Z200 | |

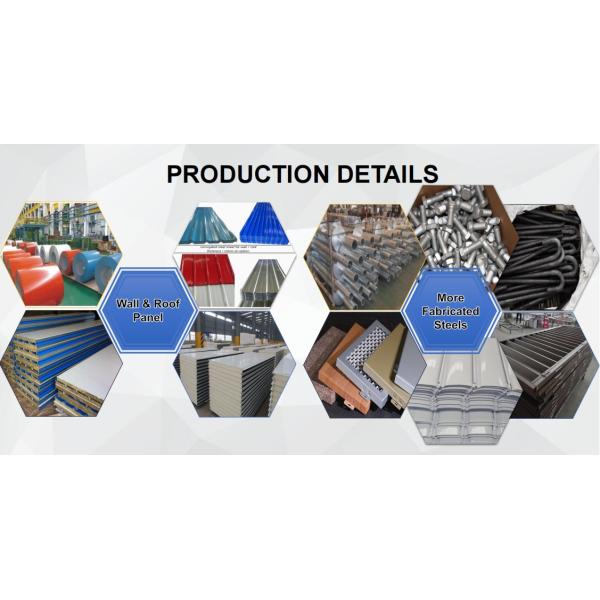

| 7. Roof and wall panel: Single steel sheet: thickness 0.326~0.8mm Sandwich panel: thickness 50mm~100mm | |

| 8. Accessories: Semi-transparent skylight belts, Ventilators, down pipe, galvanized gutter, etc | |

| 9. Surface treatment of steel: 2 layer epoxy zinc rich primer and 2 layer antirust paint |

The connection of plates and columns of steel structure workshops are generally divided into two types: flexible connection and rigid connection. The connection should be safe and reliable and easy to manufacture, install and repair.

1. Flexible connection

The characteristic of the flexible connection is that the wallboard between the house frame and the board between the board can be relatively independently displaced within a certain small range. And it can be better to adpat the deformation caused by vibration.

The structure of flexible connection generally includes bolt hook connection, steel angle hook connection and bead flexible connection.

2. Rigid connection

Rigid connection is to weld each plate and the column together with section steel, without additional steel support. The weight of the wallboard is completely borne by the column and the amount of connecting steel is small. But the relative independent displacement between the wallboard and the frame is lost. In the conditions of vibration and uneven settlement, the wall is easy to crack and damage.

3. Treatment of panels seam

The first requirement for the seam treatment is waterproofing. And the convenience of processing should be considered. For thermal insulation panels, the thermal insulation requirements should be meet. According to different situations, it can be made into various forms.

Horizontal seams can be made into flat seams, concave-convex staggered seams, tongue-and-groove seams, etc. Comprehensive consideration of different factors such as manufacturing, construction and preventing rainwater gravity and wind penetration, staggered seams are good, so this form is widely used.