Product Description:

1-3 Screen Deck Carbon Steel Gyratory Screen Machine Separator For Frac Sand

The Gyratory Screen Machine Separator is a type of rectangular sifter that is commonly used in various industries for efficient and effective screening of materials. It is also known as a rectangular separator or a rectangular gyratory sifter. This machine is designed to meet the needs of different industries and can be customized to specific requirements.the Gyratory Screen Machine is a versatile and efficient rectangular sifter that can be customized to meet the specific needs of different industries. It is made of high-quality materials, offers easy maintenance, and is equipped with a powerful motor and a large screening area, making it the ideal choice for all your screening needs.

The Gyratory Separator is available in different sizes, with a screening area ranging from 3-7.2m2. This allows for a large amount of material to be screened at once, increasing efficiency and productivity. The size of the screening area can also be customized to meet the specific needs of our customers.

Technical Parameters:

| Product Name | Gyratory Screen Machine Separator |

| Customized Service | Support |

| Power | 1.5-7.5kw |

| Screening Maintenance | Easy |

| Screen Deck | 1~8 |

| Screening Area | 3-7.2m2 |

| Structural Material | Stainless Steel304/316L, Carbon Steel |

| Capacity | 5-70 Tons/hour |

| Screen Mesh | 2~600 Mesh |

Features:

Features

1. High screening accuracy: the gyratory motion of the screen deck ensures a thorough and precise screening process.

2. Customizable screen deck: the number of layers can be adjusted to meet different capacity requirements.

3. Durable materials: the use of Stainless Steel304/316L and Carbon Steel ensures a long lifespan of the machine.

4. Easy to clean: the smooth surface of the screen deck and the detachable parts make cleaning and maintenance a breeze.

5. Low noise and energy consumption: the specially designed motor reduces noise and saves energy.

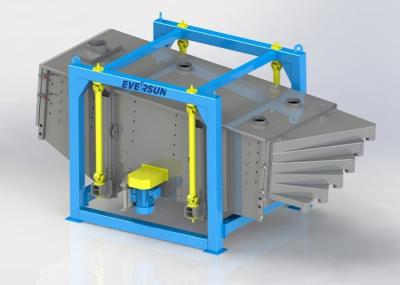

Structure:

Structure of Gyratory Screen Machine Separator

The Gyratory Screen Machine is made of high-quality structural materials, including Stainless Steel304/316L and Carbon Steel. It consists of a square gyratory sieve, a screen deck, and a motor. The screen deck can be customized with 1 to 8 layers, depending on the application and desired capacity. The Gyratory Screen Machine is responsible for the gyratory motion of the screen deck, while the motor provides the necessary power for the screening process.

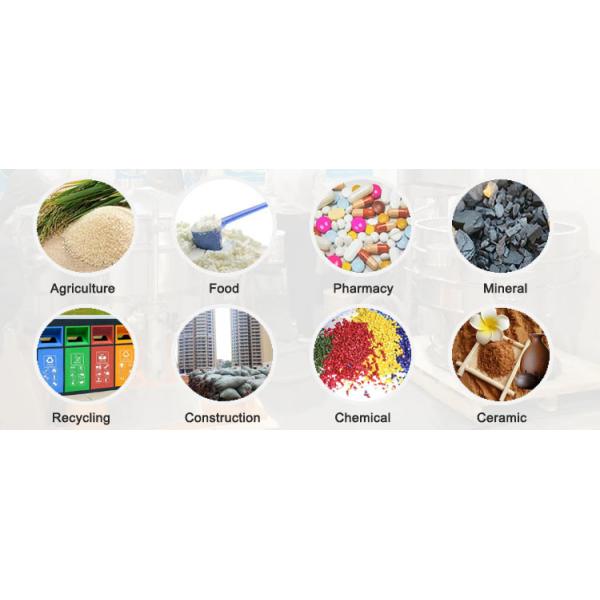

Applications:

Application

The Gyratory Screen Machine is suitable for a wide range of applications in industries such as food and beverage, pharmaceuticals, chemicals, ceramics, and more. It can be used to screen and grade various materials, including powders, granules, and liquids. Some common applications include:

- Food and beverage: sifting flour, sugar, spices, coffee, milk powder, etc.

- Pharmaceuticals: separating different sized pills, powders, and granules.

- Chemicals: grading and classifying chemicals for production processes.

- Ceramics: removing impurities and ensuring product quality.

Packing and Shipping:

Packaging and Shipping for Gyratory Screen Machine

1. Packaging:

- The Gyratory Screen Machine will be packed in a sturdy wooden case to ensure safe transportation.

- All parts and components will be securely wrapped and cushioned with foam to prevent any damage during shipping.

- The wooden case will be labeled with the product name, model number, and shipping information for easy identification.

- Customized packaging options are available upon request.

2. Shipping:

- The Gyratory Screen Machine will be shipped via sea, air, or land depending on the customer's preference and location.

- We will work with reliable and efficient shipping companies to ensure timely delivery and safe handling of the product.

- Customers will be provided with a tracking number and updates on the shipping status of their order.

- For international shipments, all necessary customs documentation will be prepared and included with the shipment to avoid any delays.

- Shipping costs will be calculated based on the destination and mode of transportation.

3. Delivery Time:

The delivery time for the Gyratory Screen Machine will vary depending on the customer's location and shipping method chosen. We will provide an estimated delivery date upon order confirmation.

4. Installation and Training:

Our team of experienced technicians can provide installation and training services upon request. Additional charges may apply.