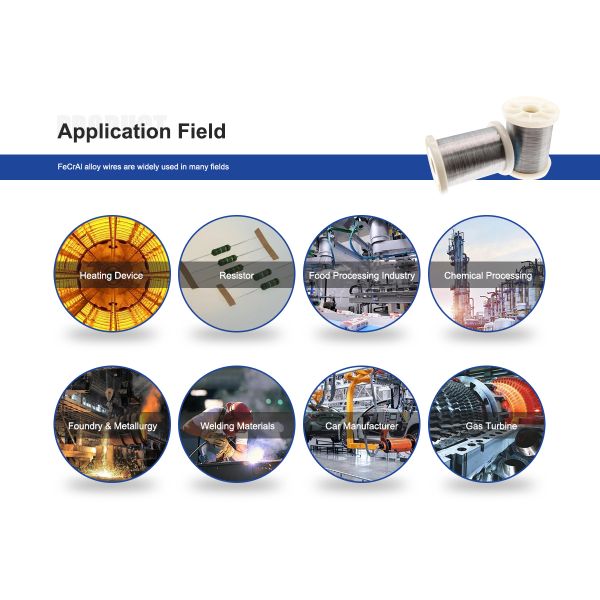

1. Heating elements: FeCrAl wire is extensively used as heating elements in appliances such as electric ovens, toasters, industrial furnaces, and kilns. Its high resistance to oxidation and excellent heat resistance make it suitable for these high-temperature heating applications.

2. Electrical industry: FeCrAl wire is utilized in the electrical industry for applications such as resistors, heating coils, and electrical heating elements. Its high electrical resistivity and ability to withstand elevated temperatures make it suitable for these electrical heating applications.

3. Automotive industry: FeCrAl wire finds application in the automotive industry for components such as oxygen sensors, spark plug resistors, and electrical connectors. Its resistance to high temperatures and corrosion makes it suitable for these automotive applications.

4. Industrial heating and drying: FeCrAl wire is employed in industrial heating and drying processes, including heat treatment, annealing, and drying of materials. It is used in equipment such as industrial dryers, heat treatment furnaces, and annealing ovens.

5. Aerospace industry: FeCrAl wire is used in the aerospace industry for applications such as heating elements, temperature sensors, and electrical connectors. Its high-temperature resistance and ability to withstand harsh environments make it suitable for aerospace applications.

6. Food processing industry: FeCrAl wire finds application in the food processing industry for equipment such as electric grills, cooking appliances, and heating elements in commercial ovens. Its high-temperature resistance and corrosion resistance make it suitable for these food processing applications.

In summary, FeCrAl wire is employed in industries that require high-temperature resistance, oxidation resistance, and electrical heating properties. Its applications include heating elements, electrical industry, automotive industry, industrial heating and drying, aerospace industry, food processing industry, petrochemical industry, and research and development.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)